| Availability: | |

|---|---|

| Quantity: | |

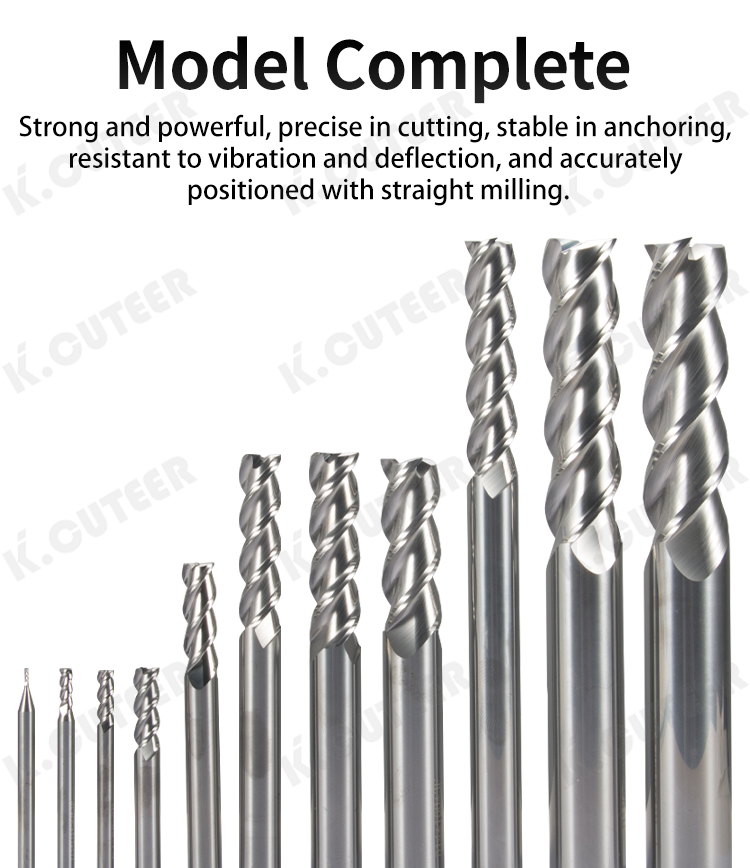

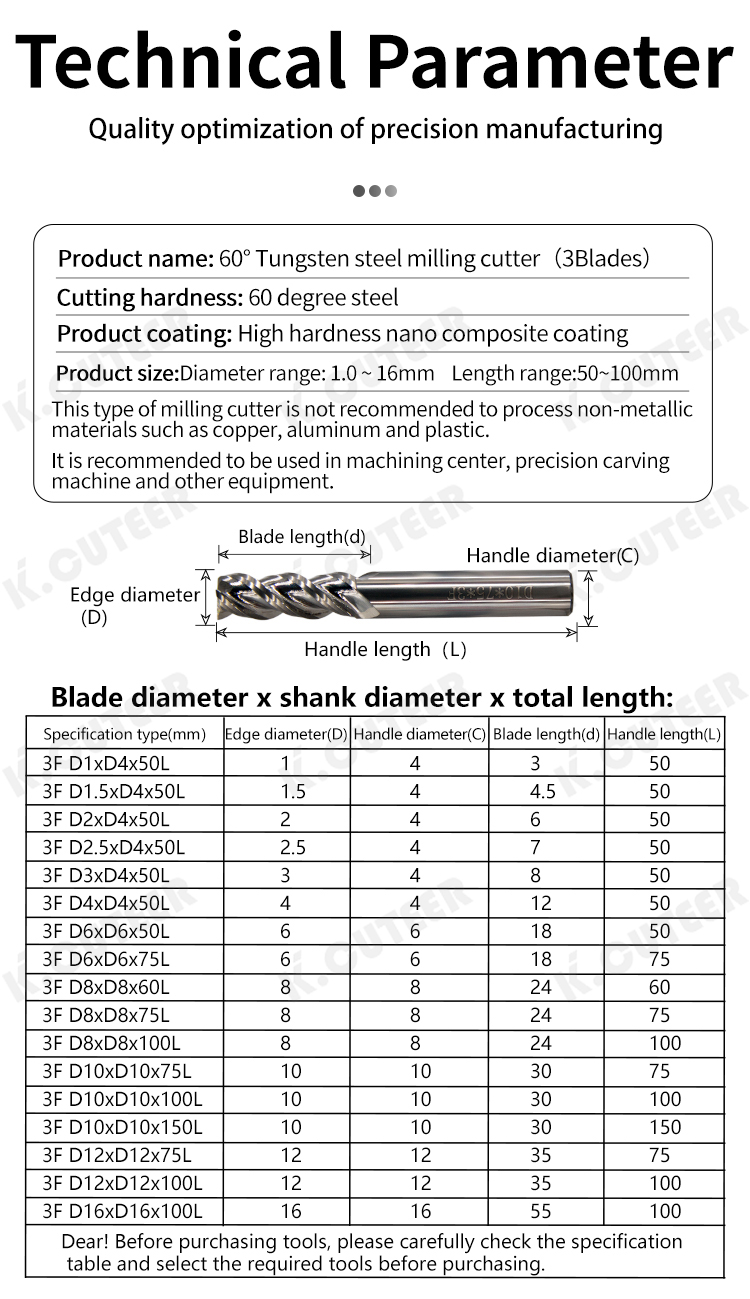

Specification:

Item:3 Flutes Tungsten Steel End Mill

HRC:60

Coating:TiALN

Flute:3

Material:tungsten steel

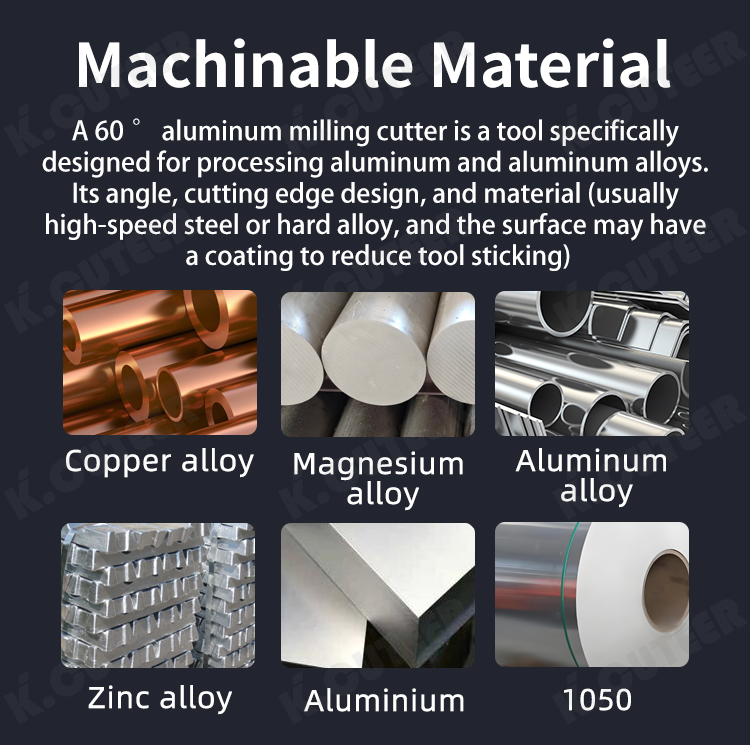

Suitable for:aluminium parts with hardness less than 60.

Feature:

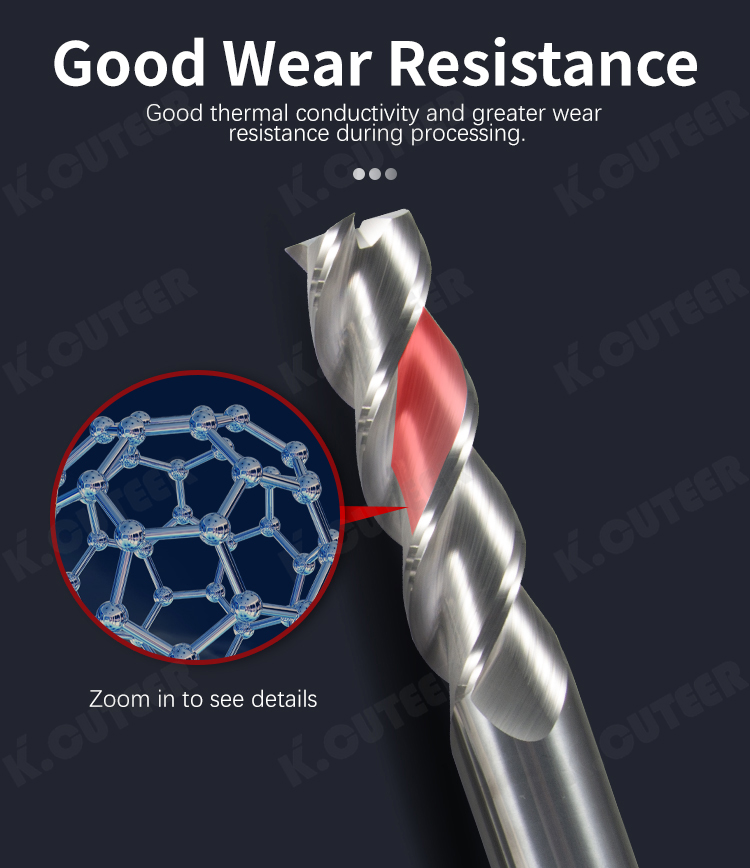

1.Material & Construction: Made from super-micro grain tungsten carbide (solid carbide), which provides exceptional hardness, wear resistance, and rigidity, allowing for high-speed machining and long tool life .

2.Flute Design: The three-flute design offers an excellent balance between efficient chip evacuation and tool strength. It often provides a better surface finish and higher feed rates compared to two-flute end mills while maintaining greater stability than four-flute tools in specific applications. Some designs feature a variable helix to minimize vibration and ensure a smoother cutting process .

3.Point Angle: The 60° point angle is typically engineered for specific machining tasks. It is particularly well-suited for chamfering and milling 60° grooves or threads. This geometry facilitates precise angular cuts.

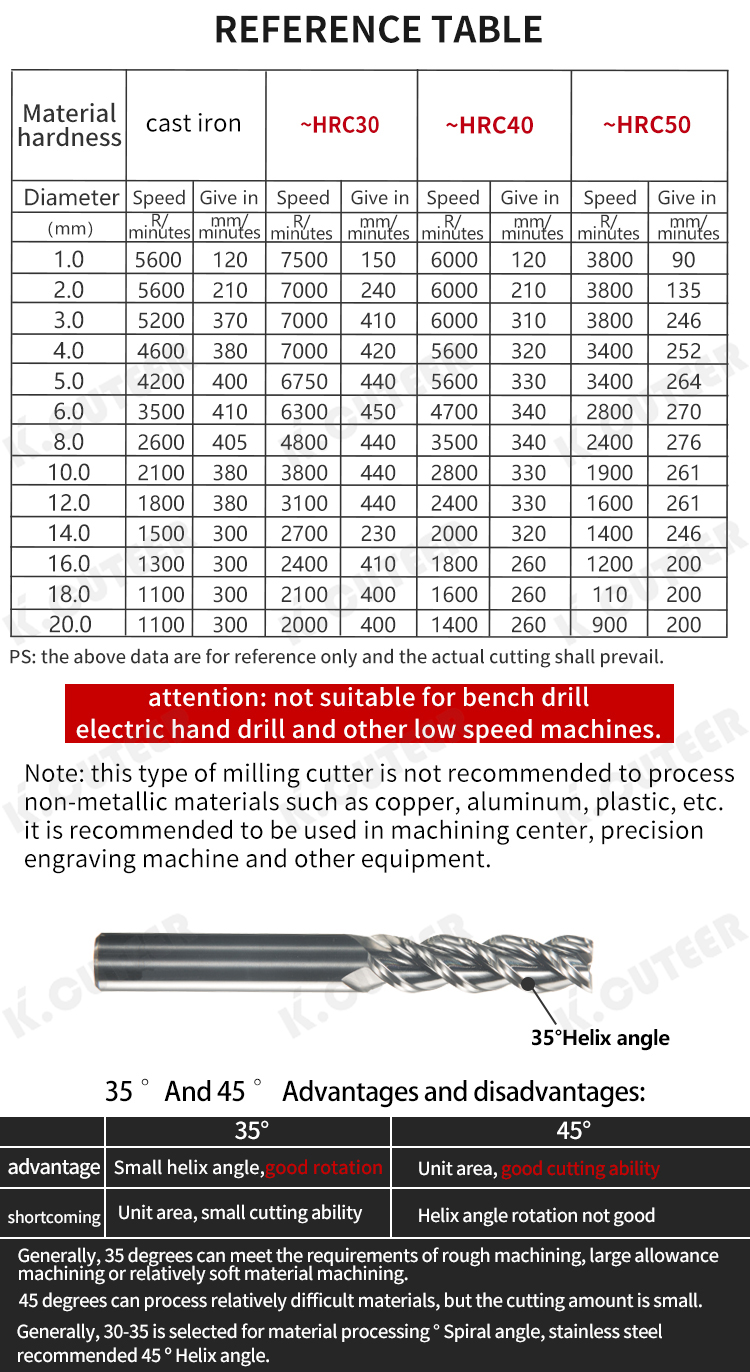

4.Helix Angle: These end mills may come with different helix angles (e.g., 45° or 50°) optimized for different materials. A higher helix angle can promote smoother cutting and better surface finish in certain alloys .

5.Cutting Edge Design: Many models incorporate unique designs such as an arc relief angle to enhance chip breaking and evacuation, contributing to stable cutting and extended tool life .

6.Coatings: They are often available with advanced coatings (such as AlCrN, TiAlN, etc.) that significantly increase heat and wear resistance, allowing the tool to withstand higher temperatures generated during cutting and further prolonging its service life .

Applications:

This type of end mill is versatile and can be used for:

Chamfering edges at a 60-degree angle.

Milling 60° V-grooves.

Thread milling of 60° threads (e.g., standard metric or Unified thread forms).

Shoulder milling and slotting in various materials, including steel, stainless steel, cast iron, and heat-treated materials (depending on the specific tool grade and coating).