| Availability: | |

|---|---|

| Quantity: | |

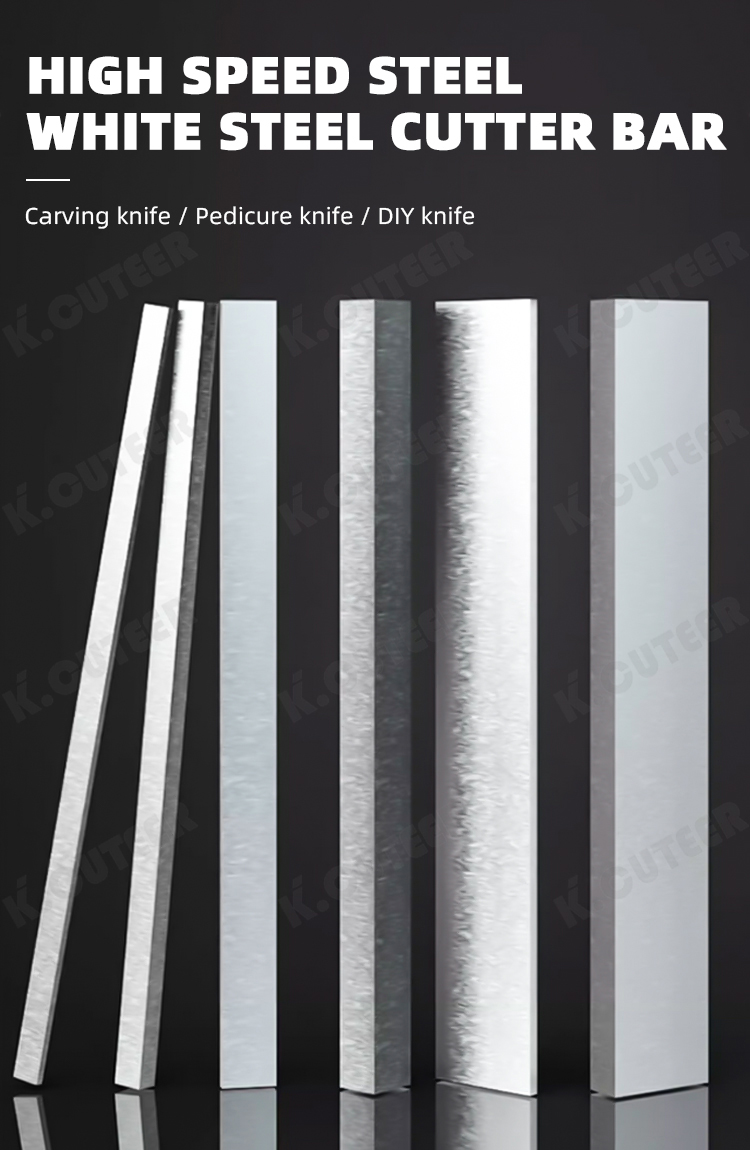

Key Features & Benefits

Excellent Toughness: H-S-S is significantly tougher and more resistant to chipping and breakage than harder but more brittle materials like carbide. This makes it ideal for applications with intermittent cuts, unstable conditions, or complex tool geometries like drills and taps.

Good Wear Resistance: While not as wear-resistant as carbide, it offers superior wear resistance compared to carbon tool steels, allowing for effective machining of a wide range of materials.

Ease of Resharpening: H-S-S tools can be easily and repeatedly sharpened using conventional grinding wheels, which simplifies maintenance and extends their service life.

Cost-Effectiveness: For many applications, especially in low-to-medium volume production or on less rigid machines, H-S-S tools provide an excellent balance of performance and cost.

Versatility: It is suitable for machining a wide array of materials, including carbon steel, alloy steel, stainless steel, cast iron, and non-ferrous metals.

Common Tool Types & Applications

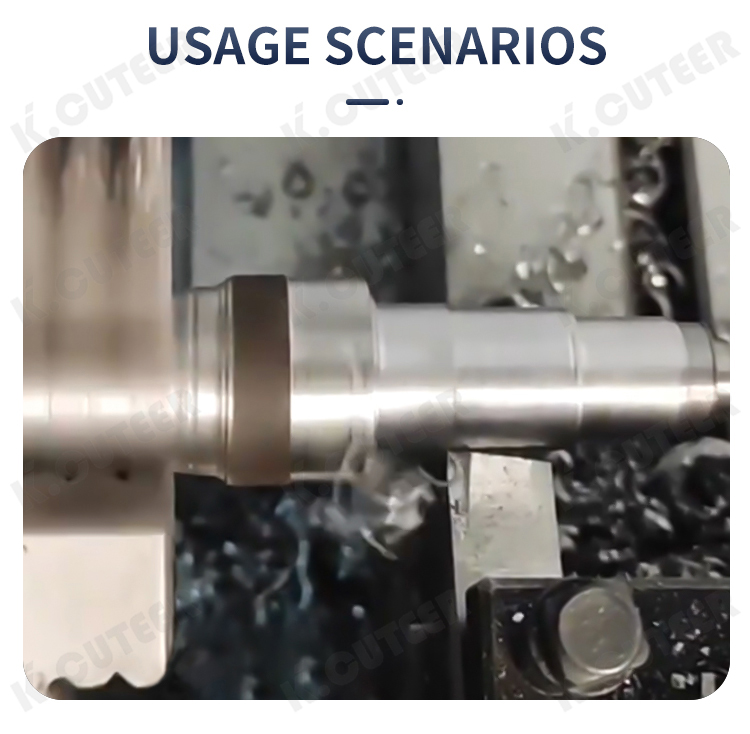

General-purpose machining on mills, lathes, and drill presses.

Intermittent cutting operations.

Low-speed and low-rigidity machining conditions.

Situations where tool toughness is more critical than extreme heat resistance.

Tools: Widely used in the manufacture of drill bits, taps, dies, reamers, end mills, and gear cutters.

Applications:

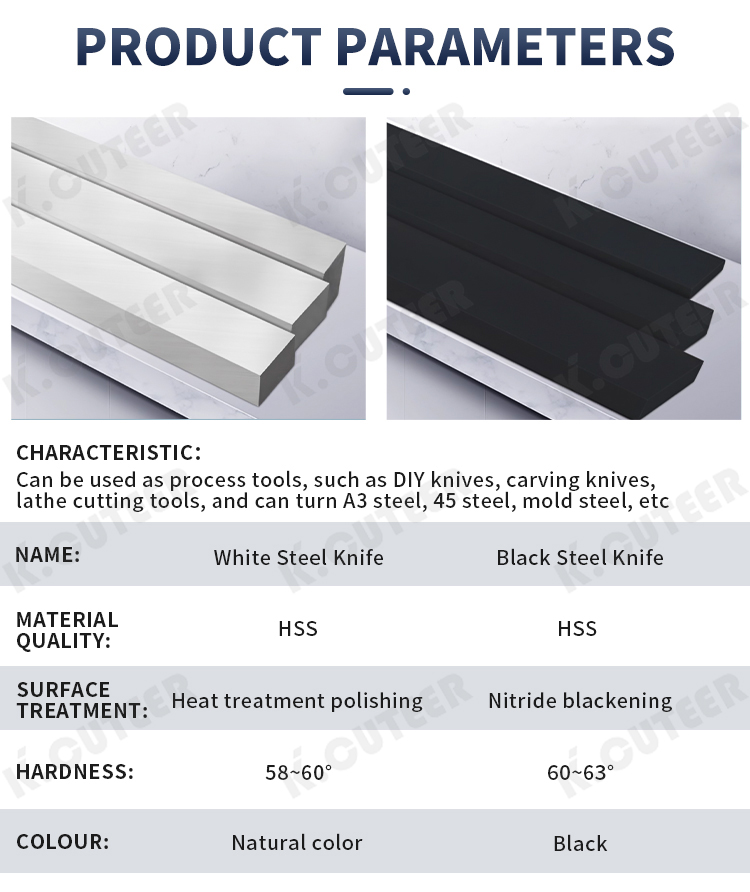

Material Composition

The key alloying elements in H-S-S are Tungsten (W), Molybdenum (Mo), Chromium (Cr), and Vanadium (V). These elements contribute to its hot hardness, wear resistance, and ability to hold a cutting edge.