| Availability: | |

|---|---|

| Quantity: | |

Specification:

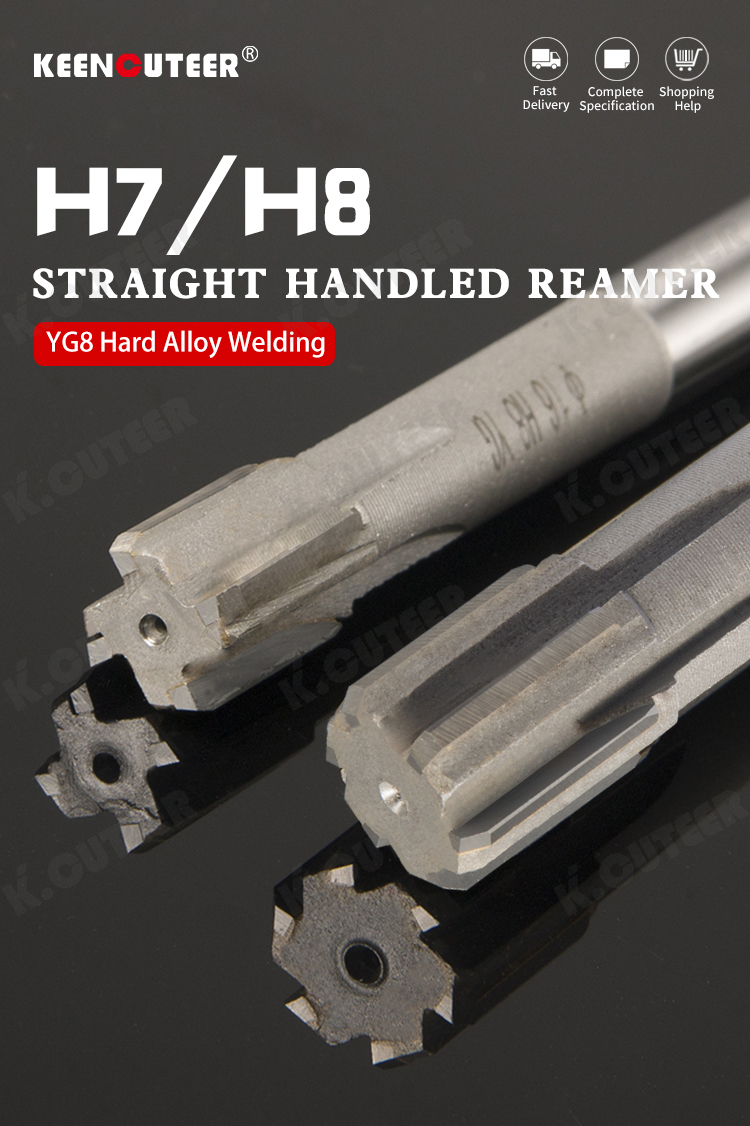

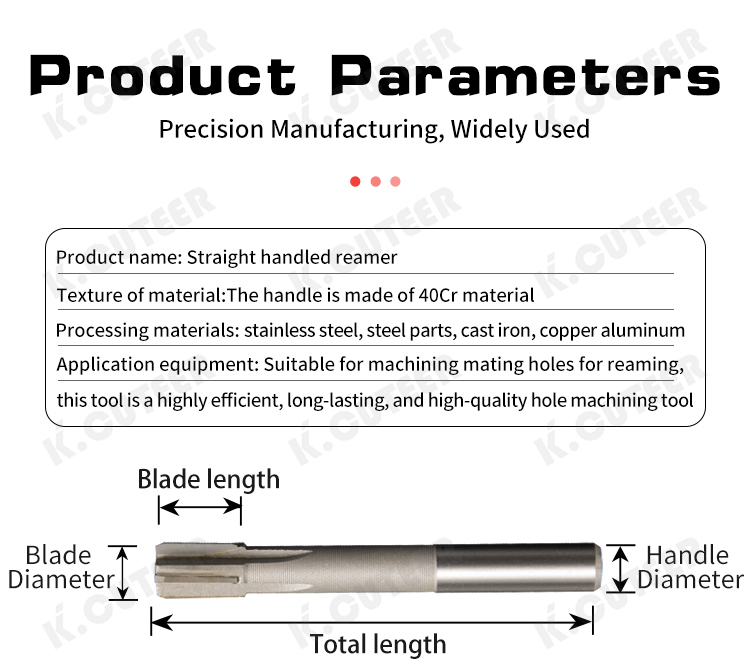

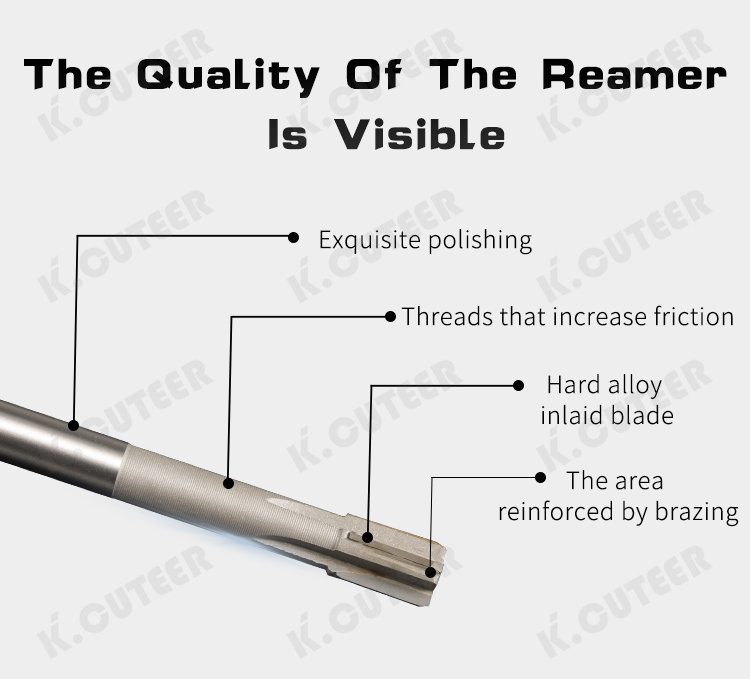

Product Name: Straight Shank Reamer

Material texture: handle made of 40Cr material, cutter head is inlaid tungsten steel alloy

Precision: H7/H8

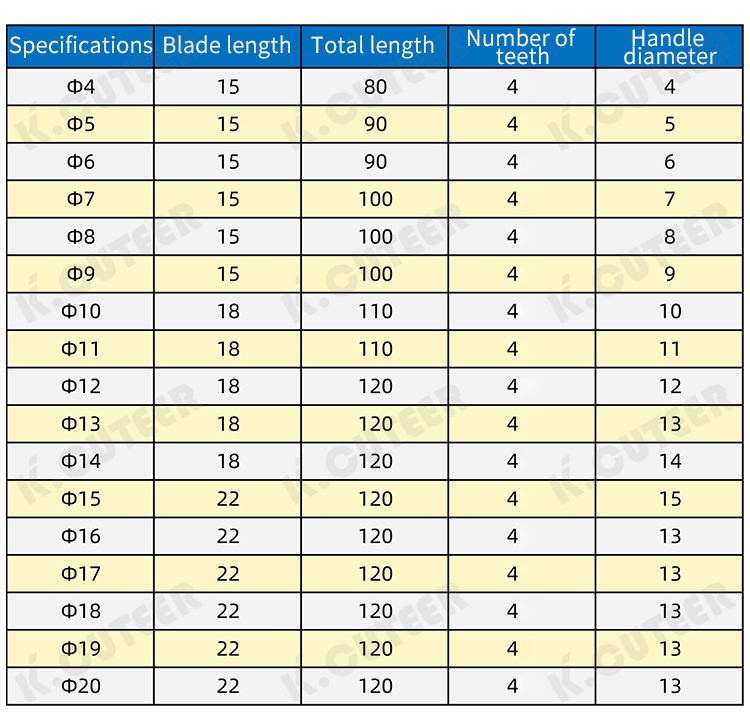

Model: 6mm-20mm

Flute: 4

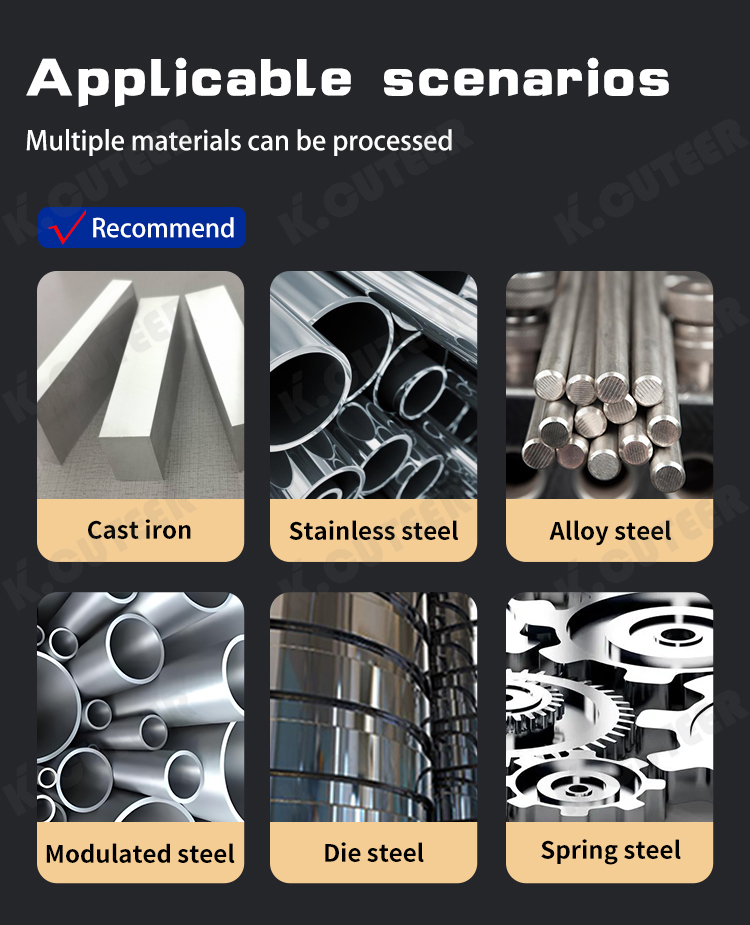

Material: Stainless steel, steel parts, cast iron, copper and aluminum.

Application equipment: Suitable for machining reamed holes.The tool is an efficient, durable, high-quality hole processing tool Tolerance

requirements: H7 = 0~0.015mm/H8=0~0.022mm

Package Included:1 PCS

Key Characteristics and Features:

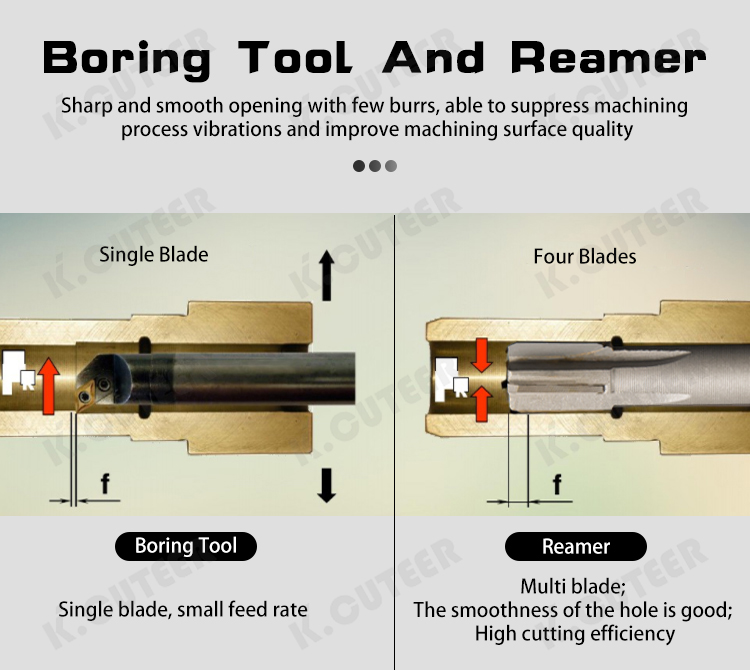

Precision Finishing:

The primary function is to remove a small amount of material from a pre-drilled hole to achieve tight dimensional tolerances, excellent roundness, and a superior surface finish.

Straight Shank Design:

The uniform cylindrical shank ensures easy and secure clamping in a wide range of common machine tool holders (e.g., drill presses, milling machines). This offers great versatility across different machines.

Flute Configuration:

Available with straight flutes or spiral flutes.

Straight Flutes: Provide good stability and are cost-effective; suitable for general-purpose reaming and materials that produce short chips.

Spiral Flutes: Offer smoother cutting action and better chip evacuation; ideal for interrupted holes or materials that produce stringy chips.

Cutting Geometry:

The cutting edges are precisely ground with a narrow land margin that guides the tool in the hole, ensuring stability and maintaining the hole's straightness.

Materials and Coatings:

Commonly made from High-Speed Steel (HSS) for general applications, Cobalt HSS for tougher materials, or Carbide for high-production and abrasive materials.

Often feature wear-resistant coatings (e.g., TiN, TiCN, TiAlN) to enhance tool life and performance.

Applications:

Straight shank reamers are used in a vast array of industries for precision hole finishing. Typical applications include:

Finishing holes for bearing seats.

Sizing holes for precision pins (e.g., dowel pins).

Achieving final bore dimensions in components before assembly.

They are suitable for machining various materials, including steel, cast iron, aluminum, and plastics.

In summary, the straight shank reamer is a fundamental and versatile tool for achieving high-precision, finished holes. Its straightforward shank design makes it widely compatible and essential for any machining process where hole quality and accuracy are critical.