| Availability: | |

|---|---|

| Quantity: | |

Technical Highlights:

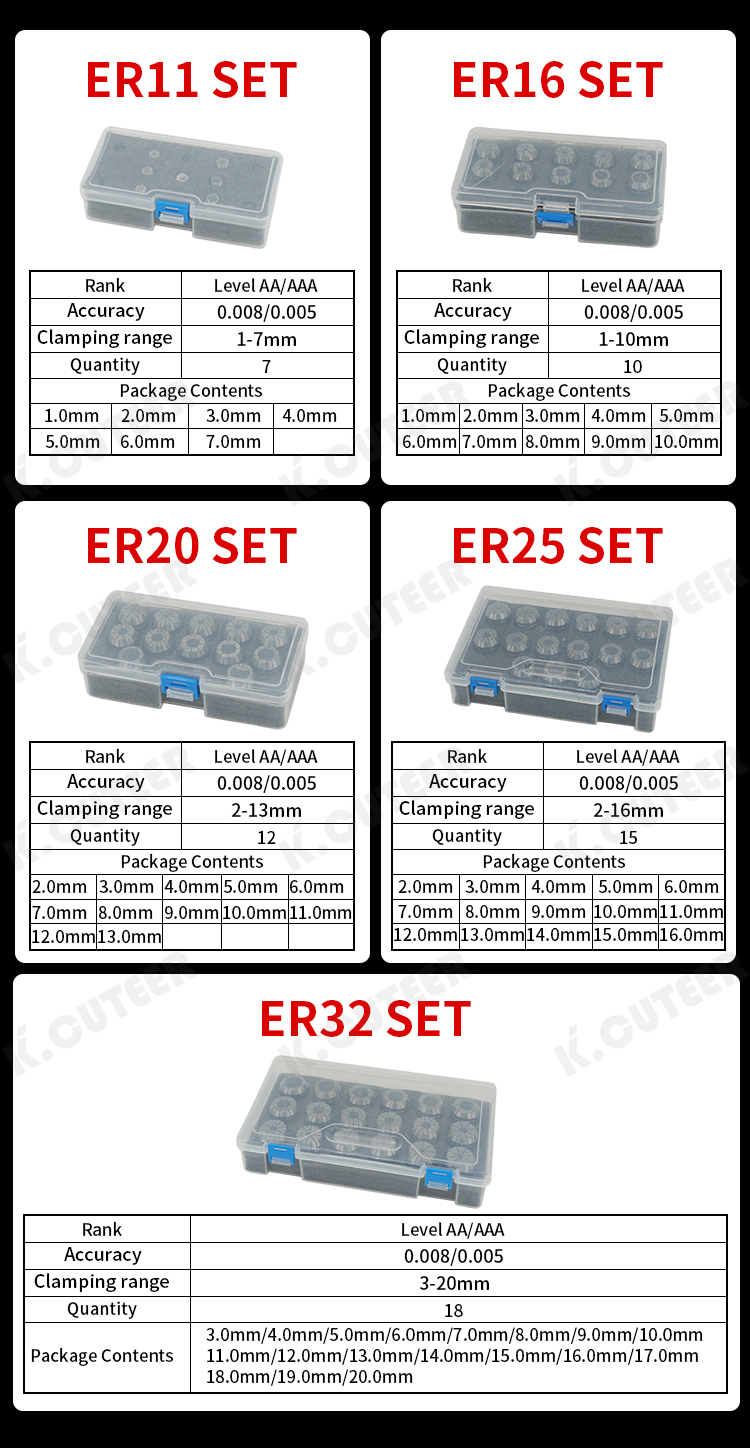

Exceptional Accuracy: These collets are manufactured to very tight tolerances. High-precision collet chucks utilizing these collets can achieve runout accuracies of around 0.00012" (3 µm) at 3 times the diameter, which is crucial for fine finishing and maintaining tight tolerances.

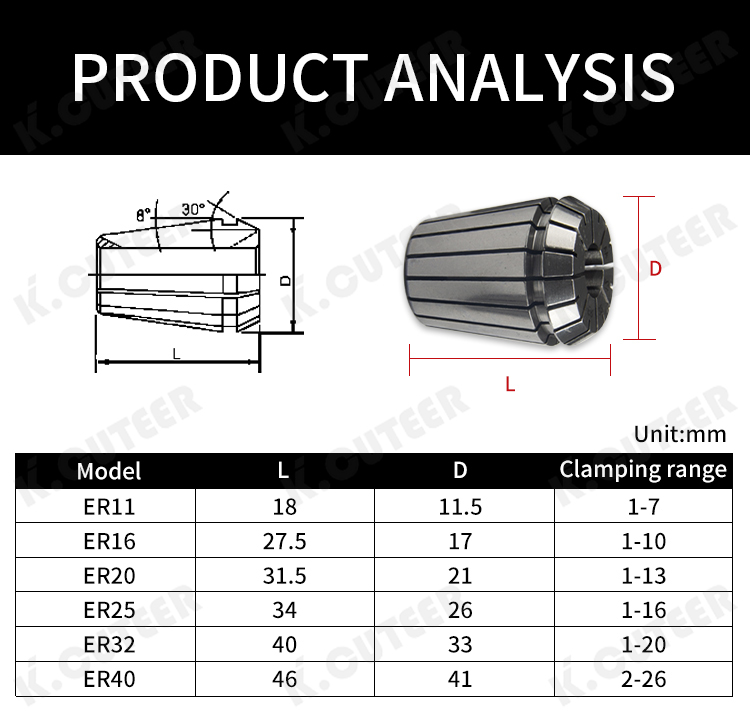

Large Clamping Range: ER collets are known for their generous clamping range. For example, ER collets from sizes like ER16, ER20, ER25, ER32, and ER40 typically have a compression range of 1 mm (.040"), reducing the number of collets needed to cover a given tool shank size range.

Rigidity and Stability: The design of the ER collet system, especially when used with precision chucks, provides high rigidity. This dampens vibrations, leads to a smoother machining process, protects the machine spindle, and allows for more aggressive cutting parameters.

Standardization: Adherence to ISO 15488 ensures that these precision collets can be used in a vast ecosystem of standard ER collet chucks and tool holders.