| Availability: | |

|---|---|

| Quantity: | |

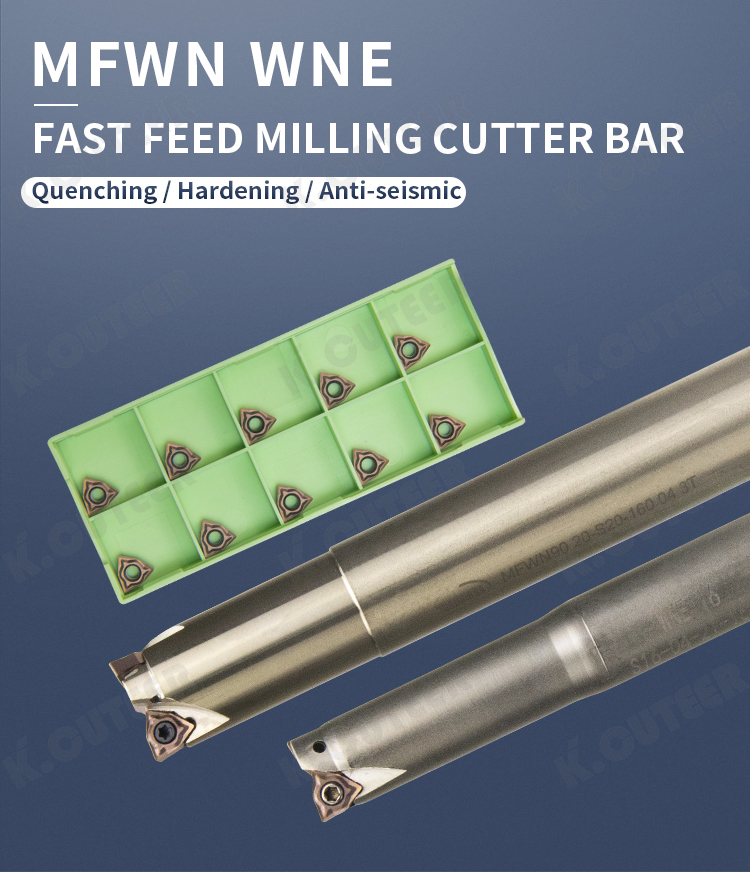

1. High-Efficiency Design

Core Principle: The inserts feature a pronounced, curved cutting edge (high positive rake) and a strong, protected cutting geometry.

Operating Method: This design enables machining at feed rates several times higher than conventional milling cutters (often ranging from 0.5 to 3.0 mm per tooth or more), even at moderate cutting speeds.

Result: It dramatically reduces machining cycle time for roughing and semi-finishing operations.

2. Superior Stability and Tool Life

Low Radial Forces: The shallow depth of cut and specialized edge geometry direct the majority of the cutting force axially along the spindle, minimizing radial deflection. This is critical for stability on long overhangs or in less rigid setups.

Extended Tool Life: Reduced vibration and lower cutting temperatures contribute to significantly longer, more predictable insert life.

3. Versatile Chip Control

Effective Chip Thinning: The insert shape creates a "chip thinning" effect, allowing the high feed per tooth to produce manageable, thin chips.

Benefit: This improves chip evacuation, reduces heat, and protects the workpiece surface.

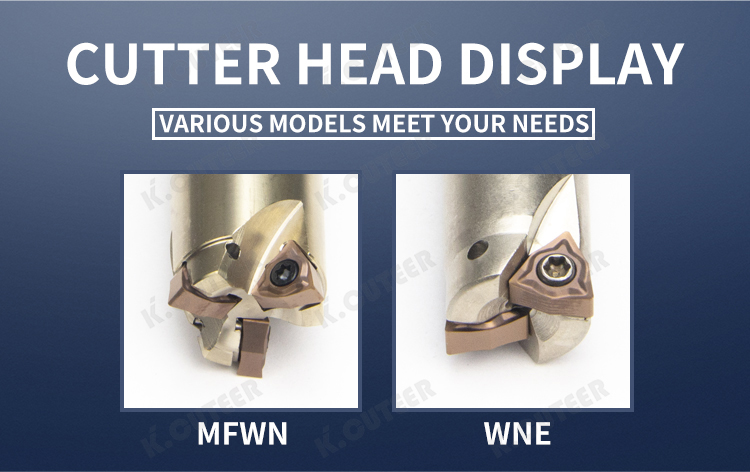

4. High-Quality Shoulder Finish

Precision: Despite being a high-feed tool, the 90-degree lead angle produces clean, square shoulders with good surface finish in a single pass, often eliminating the need for a separate finishing operation.

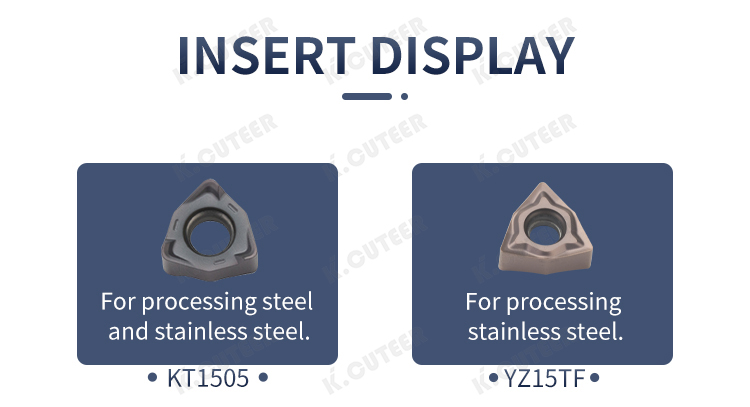

Insert Type: Primarily uses WNMU series (e.g., WNMU080408) double-sided square or octagonal inserts with 8 cutting edges.

Cooling System: Most models feature internal coolant channels (IC) for precise delivery of cutting fluid to the cutting zone, essential for high-productivity machining.

Material Application: Excellent for efficient roughing of a wide range of materials, including carbon steel, alloy steel, stainless steel, and cast iron.

High-Speed Roughing of large planar surfaces, cavities, and mold cores.

Shoulder and Face Milling where a square corner and high stock removal are required.

Machining in Challenging Conditions, such as with long tool overhangs or on components with thin walls, due to its low radial cutting forces.

| Feature | MFWN Fast-Feed Milling Cutter | Conventional Square Shoulder Milling Cutter |

|---|---|---|

| Typical Feed per Tooth (fz) | Very High (e.g., 0.8 - 3.0 mm) | Low to Medium (e.g., 0.1 - 0.4 mm) |

| Depth of Cut (ap) | Shallow (usually < 2.5mm) | Medium to Deep |

| Main Cutting Force Direction | Primarily Axial (towards the spindle) | Primarily Radial (perpendicular to the spindle) |

| Primary Advantage | Maximum Material Removal Rate, Stability | Flexibility in Depth of Cut, Slotting Capability |

In summary, the MFWN series fast-feed milling cutter is a specialized, high-productivity tool designed for modern CNC machining. Its core value lies in drastically reducing machining time through exceptionally high feed rates while providing exceptional process stability and good shoulder quality.