| Availability: | |

|---|---|

| Quantity: | |

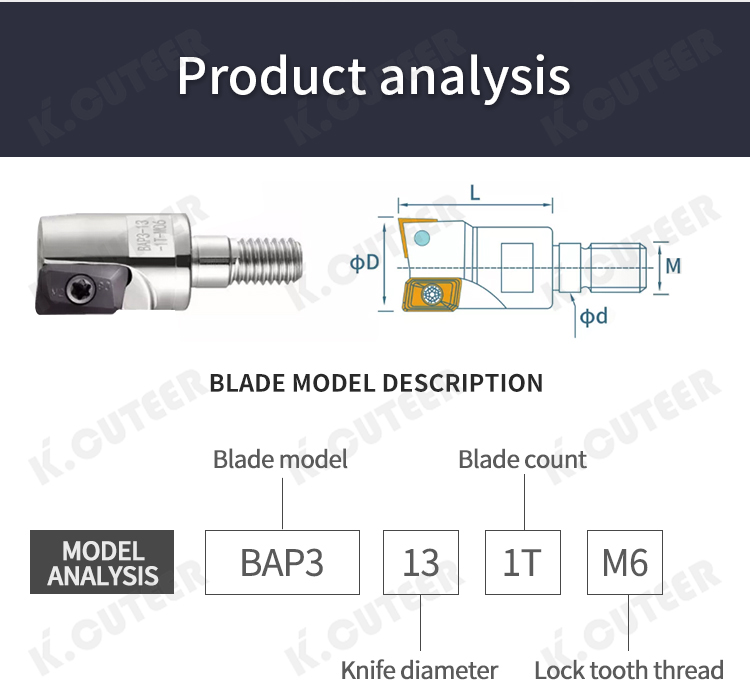

BAP Milling Cutter Head: English Introduction

1. Concise Version (For Catalogs & Quick Reference)

The BAP Milling Cutter Head is an indexable square shoulder milling cutter known for its screw-clamping mechanism. It is engineered for high-efficiency machining of 90-degree shoulders and faces, offering exceptional rigidity and stability in heavy-duty applications.

2. Standard Technical Description

The BAP Series represents a robust, screw-type indexable milling cutter head designed primarily for square shoulder milling and face milling operations. Its key characteristic is a threaded clamping system that secures positive rake inserts with exceptional force, minimizing tool deflection and vibration.

Key Features:

Screw-Lock Design: Ensures maximum insert clamping security, ideal for high-feed and heavy-cut conditions.

90° Shoulder Machining: Capable of producing true vertical shoulders and flat surfaces.

High Rigidity: Solid body construction provides superior stability, reducing chatter and improving surface finish.

Positive Rake Geometry: Facilitates freer cutting action, lower power consumption, and better chip evacuation.

Excellent Chip Evacuation: The open design allows for efficient chip flow, which is critical in deep slotting and high-volume material removal.

3. Detailed Professional Overview

BAP Indexable Milling Cutter Head: Technical Overview

The BAP milling cutter head is a premium-grade tooling solution for demanding shoulder and face milling applications on CNC machining centers. It falls under the category of screw-clamp square shoulder cutters and is distinguished by its superior clamping reliability and metal removal rates.

Technical Highlights:

Clamping Mechanism: Utilizes a central screw to directly axially clamp the wedge-seat and insert. This system offers the highest level of security, virtually eliminating the risk of insert movement during aggressive machining.

Enhanced Stability: The rigid design is particularly advantageous when machining difficult-to-cut materials like stainless steels, titanium alloys, and high-temperature alloys.

Versatile Application: Suitable for a wide range of operations, from heavy roughing to semi-finishing, across various industries including aerospace, mold & die, and general engineering.

Insert Compatibility: Typically uses standardized positive rake, rhombic-shaped inserts (such as those in the APMT or similar series), which provide multiple cutting edges and are available in various grades for different materials.

Typical Applications:

Shoulder milling

Face milling

Slot milling (depending on cutter diameter)

Heavy-duty profiling

High-productivity machining on cast iron, steel, and alloyed materials