| Availability: | |

|---|---|

| Quantity: | |

Key Features & Benefits:

1.High Precision and Accuracy: It guarantees that the tool enters the workpiece at the exact predetermined location and maintains the correct path, resulting in highly accurate hole positions and straightness.

2.Improved Tool Life: By providing rigid support and preventing tool deflection or "walking," it reduces side loads and wear on the tool, thereby extending its service life.

3.Enhanced Process Stability: It is essential for maintaining stability in high-volume production, ensuring consistent quality from the first part to the last.

4.Reduced Vibration and Chatter: The close-tolerance support dampens vibrations, leading to a smoother cutting action and better surface finish on the machined hole.

Common Applications:

1.Guide bushes are fundamental in various machining processes:

2.Jig Boring and Drilling: Used extensively in drilling jigs and fixtures for guiding tools.

3.CNC Machining: Often employed in CNC machining centers for critical hole-making operations to enhance accuracy.

4.Gun Drilling: A critical component in gun drilling systems, providing the necessary starting support and guidance for the deep-hole drilling process.

5.Mass Production: Widely used in automotive and aerospace manufacturing for repetitive, high-precision drilling tasks.

Types and Materials:

1.Types: Common types include fixed guide bushes, slip/renewable bushes (for different operations on the same hole), and linear motion bushes (for supporting shafts).

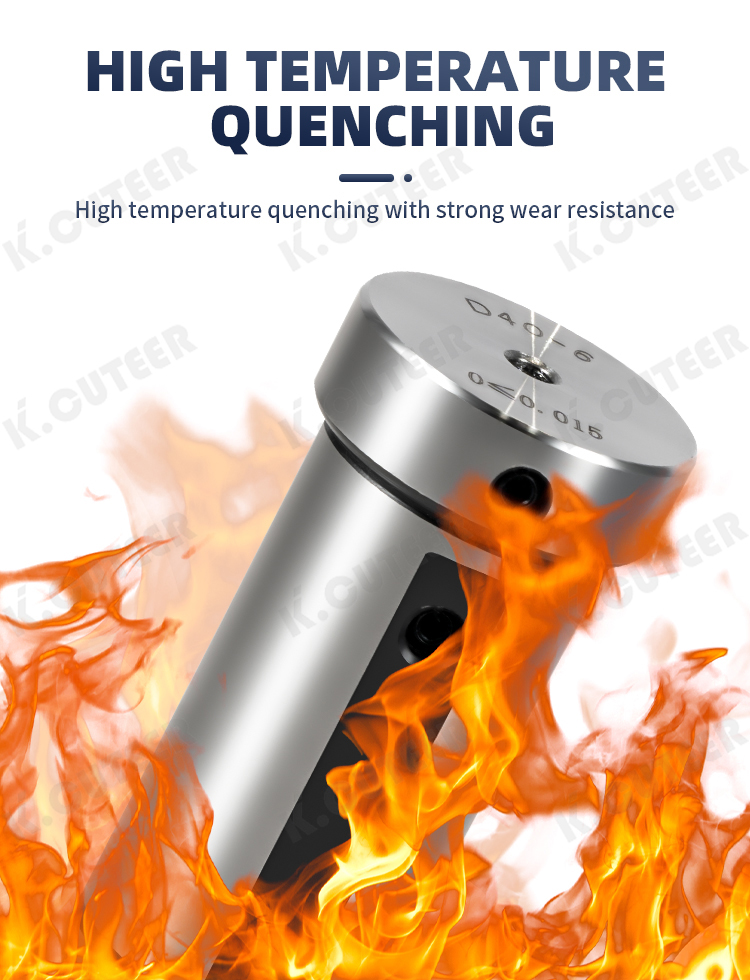

2.Materials: Typically made from high-carbon, high-chromium tool steel (like SUJ2), hardened and ground to resist wear. Some feature special liners for lubrication.