| Availability: | |

|---|---|

| Quantity: | |

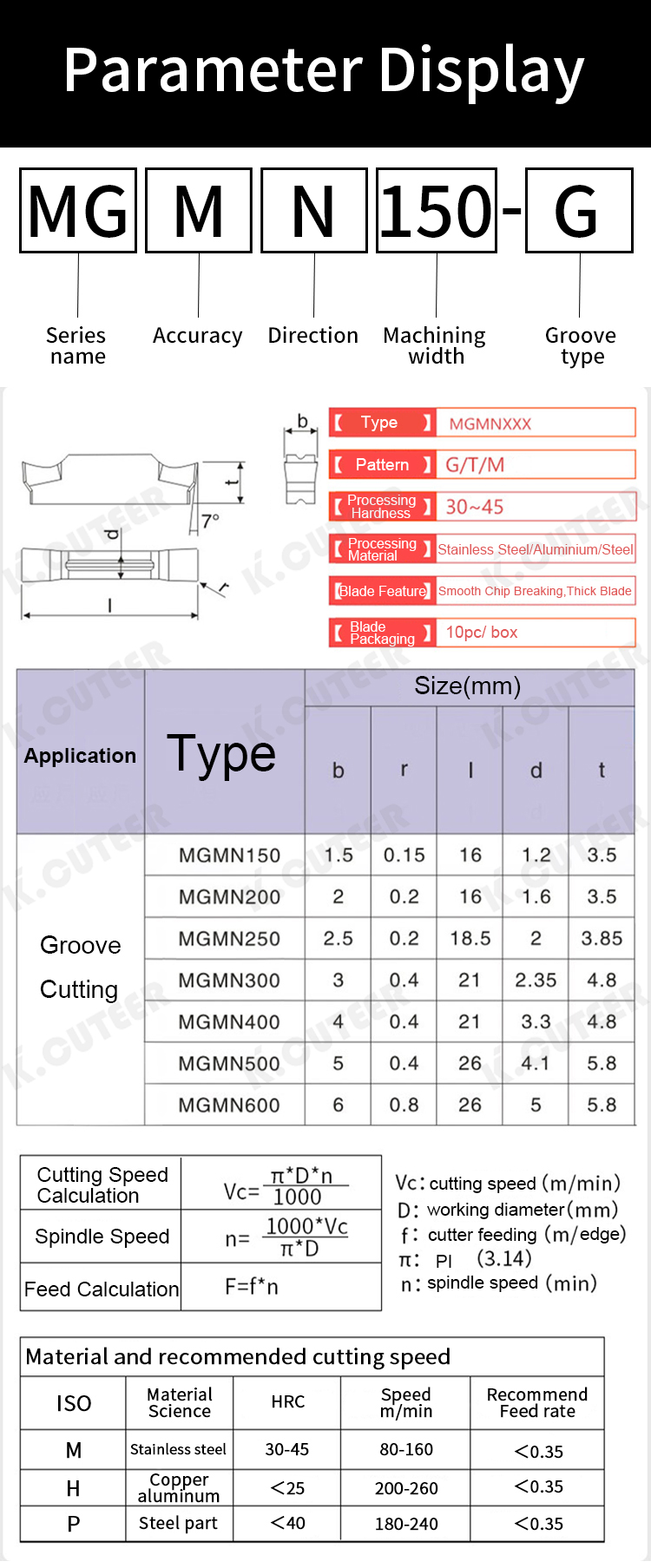

The MGMN code denotes a square-shaped, negative rake insert.

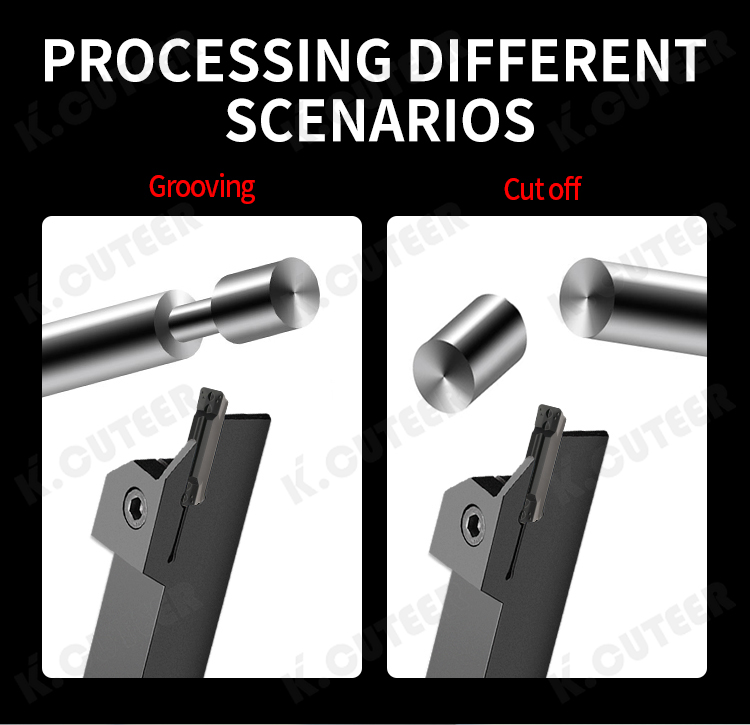

It is a versatile insert used for:

Grooving

Cut-off (parting)

Light side-turning (copying)

YZ5115 is a premium grade from ISCAR's SUMO TEC coated grade family.

It features a micro-grain carbide substrate with a specialized CVD coating.

This combination is specifically optimized to handle the highly abrasive nature of cast iron materials, providing exceptional resistance to flank wear.

Superior Abrasion Resistance: The advanced coating provides exceptional resistance to the abrasive wear caused by cast iron, leading to long and predictable tool life.

Thermal Stability: The grade maintains its hardness and integrity at the elevated temperatures generated during high-speed machining of cast iron.

High Productivity: Allows for significantly higher reliable cutting speeds compared to standard grades, reducing machining cycle times.

Predictable Performance: Offers consistent and reliable wear patterns, which is crucial for automated production environments.

This insert is ideal for:

High-speed grooving and cut-off operations on cast iron components.

Machining parts for the automotive industry (e.g., brake discs, engine blocks).

Pump and valve manufacturing.

Any application involving the machining of gray cast iron or ductile iron where maximizing tool life against abrasion is the primary goal.

In summary, the MGMN YZ5115 insert combines a versatile grooving geometry with a wear-resistant grade specifically engineered for efficient and high-productivity machining of cast iron components.