| Availability: | |

|---|---|

| Quantity: | |

Key Features :

Clamping and Positioning: The shank features a precise insert clamping mechanism at its front end. This ensures the insert remains absolutely stable under high rotational speeds and cutting forces, guaranteeing consistent machining dimensions.

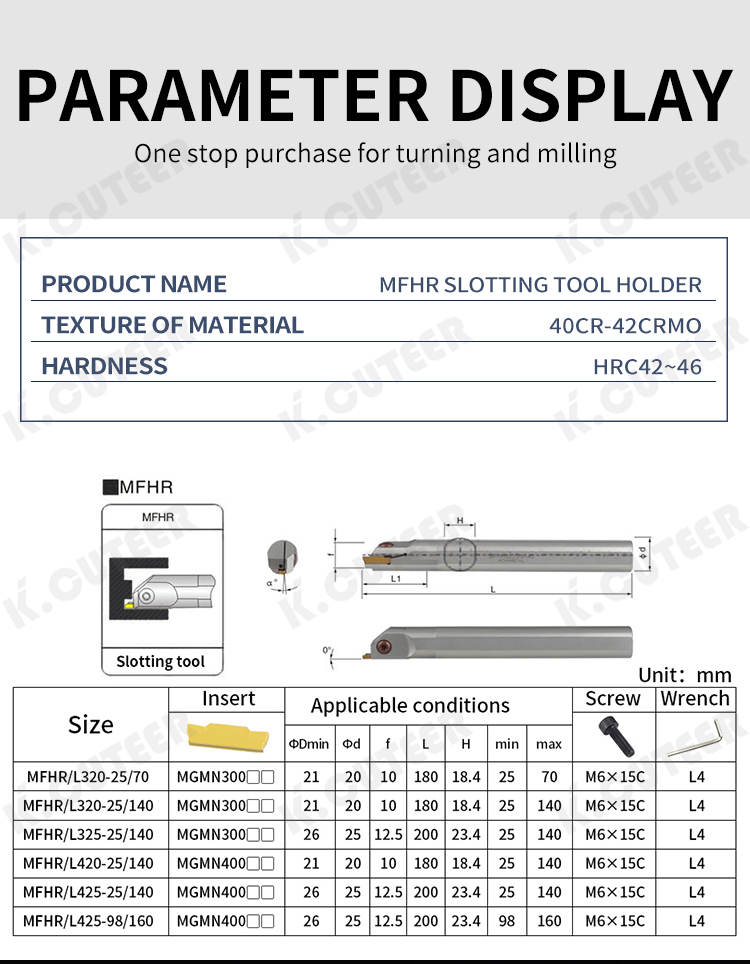

Rigid Structure: Typically manufactured from high-strength alloy steel, toolholders possess excellent resistance to deformation and vibration , allowing them to handle heavy cutting loads without deflection or vibration.

Guidance and Precision: The cutting section of the toolholder is designed for specific groove widths. It guides the insert for precise radial or axial cuts, producing grooves that meet required specifications for width, depth, and surface finish.

Coolant Delivery: Many modern toolholders incorporate integrated coolant channels (through-tool coolant capability). This delivers cutting fluid directly to the cutting edge, effectively reducing heat, improving chip evacuation, and extending tool life.

Diverse Designs: Based on application needs, toolholders are categorized into external grooving toolholders, internal (boring) grooving toolholders, and face grooving toolholders. Specialized toolholders also exist for machining specific groove profiles .