| Availability: | |

|---|---|

| Quantity: | |

Key Features and Functions:

Axial Float Compensation: This is the most critical feature of a tapping chuck. It automatically compensates for minor discrepancies between the machine spindle's feed rate and the actual pitch of the tap. Without this compensation, the lack of synchronization would easily cause tap breakage or poor thread quality.

Torque Overload Protection: Many tapping chucks incorporate an adjustable torque clutch mechanism. If the tapping torque exceeds a preset value, the clutch slips, effectively protecting the delicate tap from being twisted and broken.

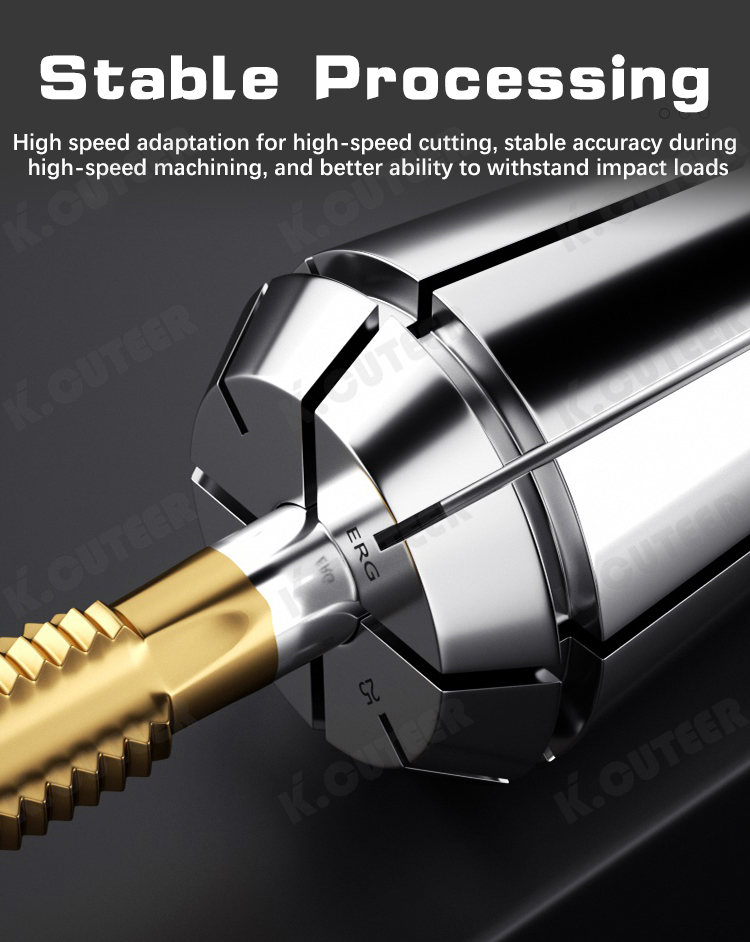

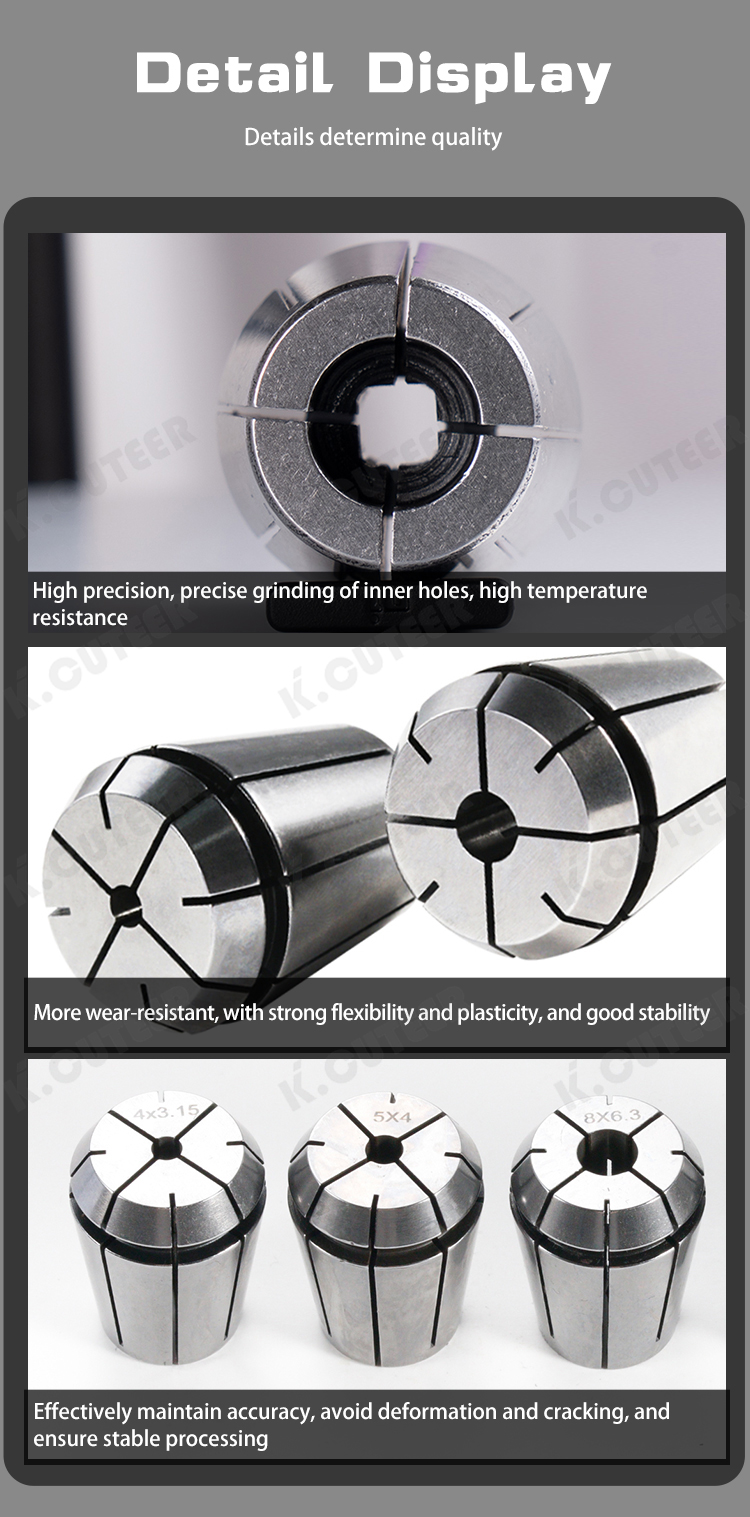

High Precision and Rigidity: They ensure the tap is aligned with the spindle centerline, minimizing radial runout to produce high-quality, precise threads.

Quick Tool Change: They are typically designed for rapid tap changes, improving production efficiency.

Working Principle:

During tapping, the machine spindle rotates and feeds downward. Thanks to the internal spring and float mechanism within the chuck, the chuck body can move axially (compress and extend) a small amount relative to the shank. This allows the tap to be "pulled" into the workpiece by its own thread lead, achieving a "self-feeding" action that perfectly matches the feed to the pitch.

Applications:

Widely used in any industry requiring precision internal thread machining, such as general machinery manufacturing, automotive, mold and die making, and aerospace.