| Availability: | |

|---|---|

| Quantity: | |

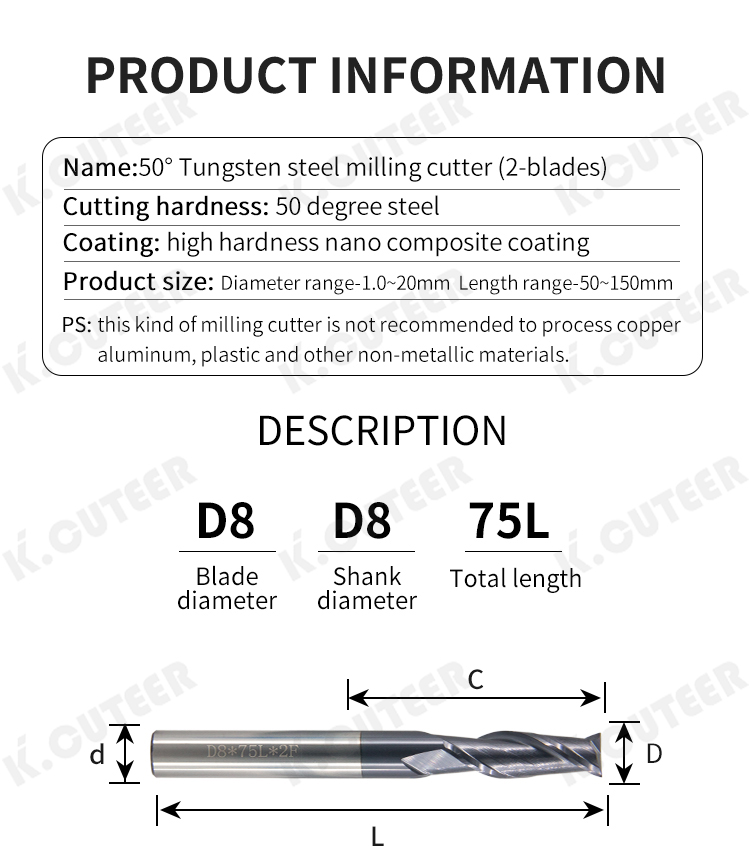

The table below summarizes common specifications and offers selection guidance.

| Feature | Typical Specification / Description | Key Points & Application Guidance |

|---|---|---|

| Material | Tungsten Carbide (Cemented Carbide) | Extremely hard and wear-resistant. More rigid than HSS but also more brittle; requires a stable machine setup-8. |

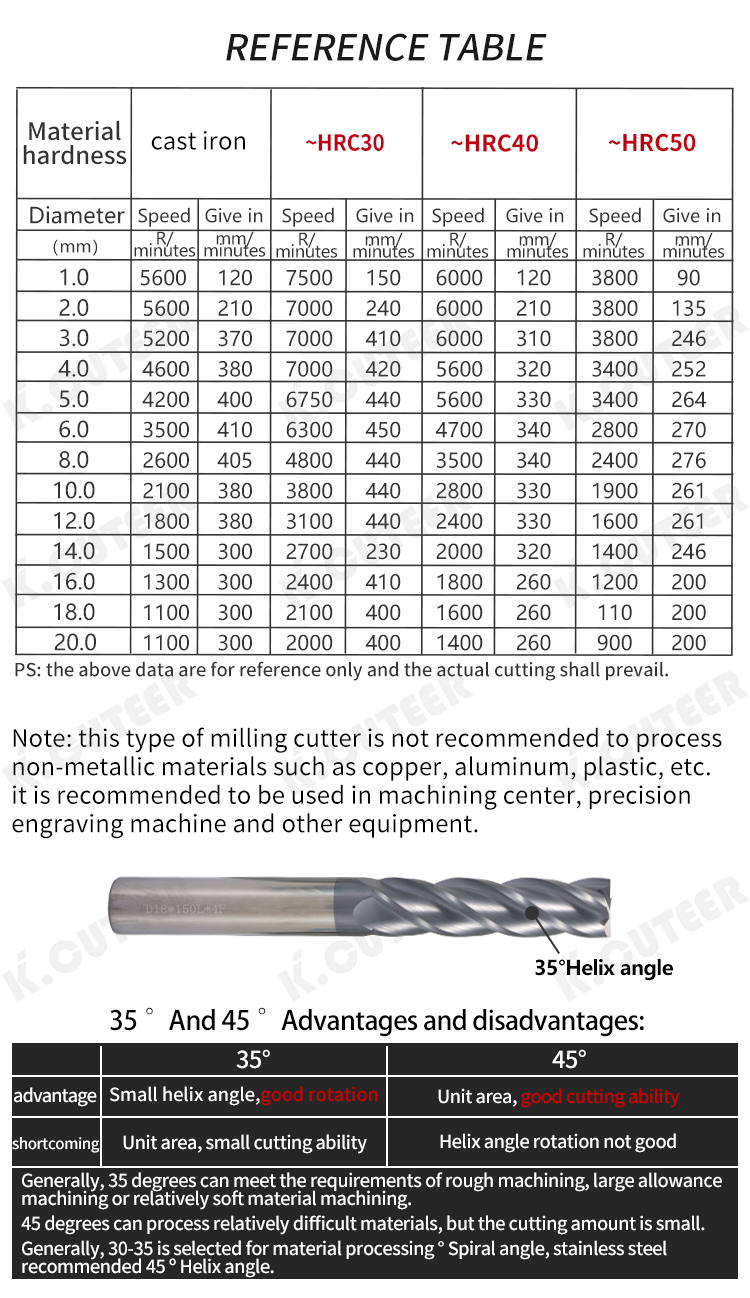

| Helix Angle | 50° (High Helix) | Promotes smooth cutting and good surface finish. Ideal for finishing operations and machining gummy materials like aluminum. |

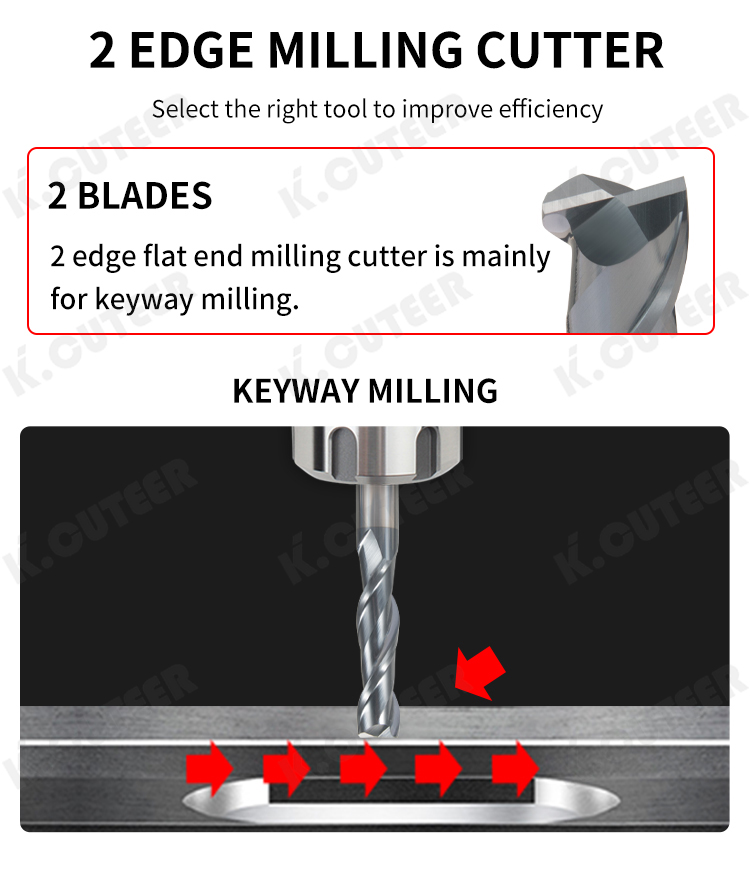

| Number of Flutes | 2 | Provides large chip spaces for excellent chip evacuation in slots and deep cavities. |

| Common Coatings | TiAlN, AlTiN, or specialized proprietary coatings | Essential for high-speed machining. Reduces friction and protects against heat and wear. The coating type should be selected based on the workpiece material. |

| Primary Applications | Plunge milling, slotting, profiling, and machining deep grooves | The 2-flute design allows for efficient axial plunging cuts. Best for operations where chip removal is critical. |

| Workpiece Materials | Alloy steel, tool steel, stainless steel, titanium alloys, aluminum | A versatile tool geometry. Ensure the specific carbide grade and coating are suitable for your target material. |

Features and Advantages are:

High Helix Angle (50°): Provides a shearing cut action, which significantly reduces cutting forces and vibration. This leads to superior surface finishes and is excellent for machining challenging materials like aluminum, stainless steel, and titanium alloys.

Two Flutes: Offers the largest possible chip gullet (space), allowing for effective chip evacuation in slotting, plunging, and pocketing operations. This prevents chip re-cutting and tool damage.

Tungsten Carbide Substrate: Provides extreme hardness, wear resistance, and rigidity compared to High-Speed Steel (HSS), enabling higher cutting speeds, longer tool life, and better performance in hard materials.

Common Coatings: Often coated with TiAlN or AlTiN to further enhance heat resistance, lubricity, and tool life, especially in dry or high-speed machining.

Typical Applications:

Slotting and Plunging: The 2-flute design is ideal for cutting full-width slots and vertical plunging operations.

Finishing Operations: The 50° helix excels at producing fine surface finishes on slopes and contours.

Machining Difficult Materials: Effective for sticky alloys (e.g., aluminum) and hard, tough materials (e.g., tool steels, Inconel).

Usage Tips:

Ensure Rigidity: A secure setup in the machine spindle and a firmly held workpiece are critical to prevent chatter and tool breakage.

Optimize Coolant: Use ample coolant or compressed air to evacuate chips, especially in deep slots, to prevent re-cutting.

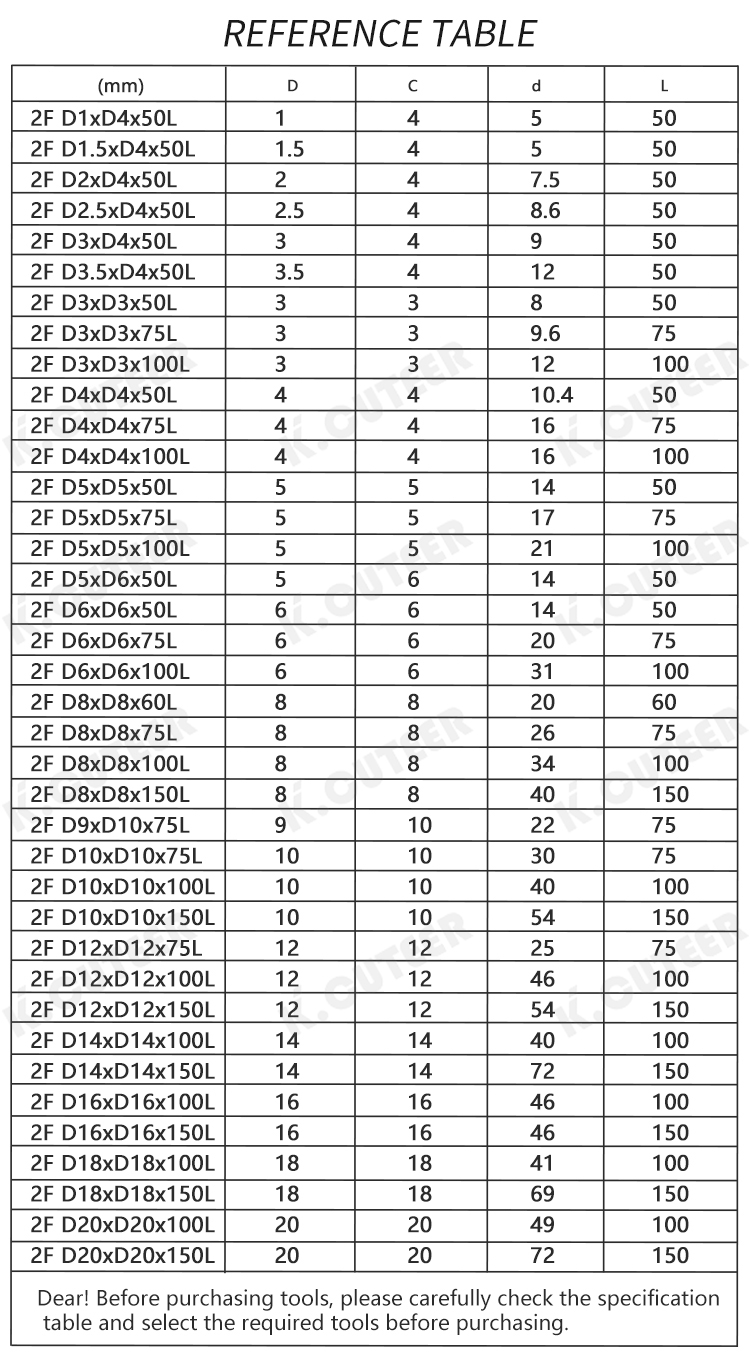

Follow Parameters: Adhere to manufacturer-recommended speeds and feeds for your specific workpiece material to balance performance and tool life.