| Availability: | |

|---|---|

| Quantity: | |

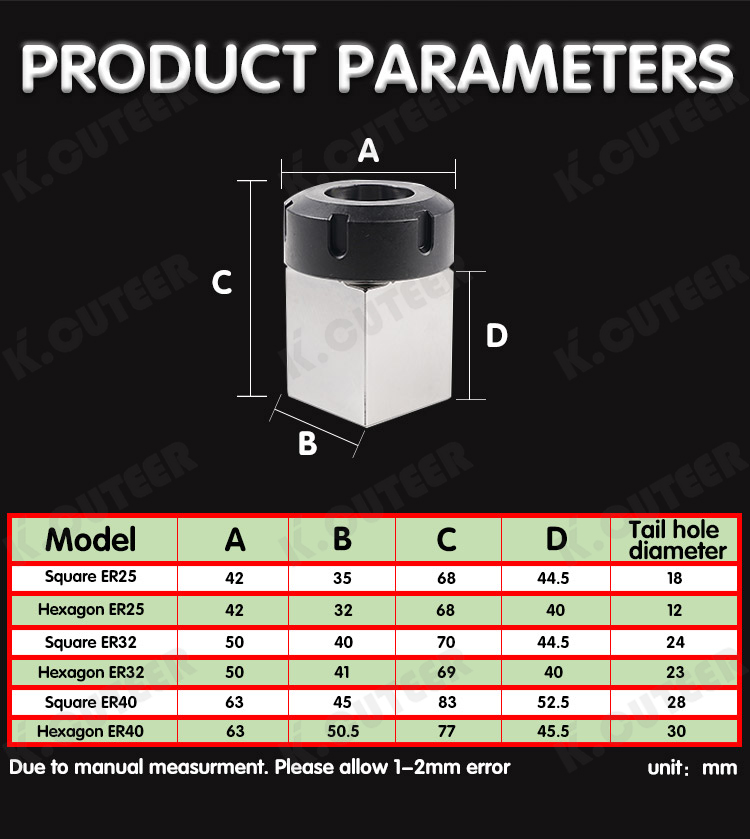

An ER Square and Hexagon Collet is a specialized type of ER collet designed not to hold cutting tools, but to act as a high-precision workholding fixture. Its primary function is to securely clamp square or hexagonal bar stock in a CNC machine (typically a lathe or mill-turn center) for machining operations.

The fundamental design principle is the same as a standard ER collet:

It fits into a standard ER collet chuck and is tightened with a standard ER nut.

The key difference is its internal bore shape, which is precision-machined to match the external profile of square or hexagonal material.

| Feature | Description | Key Benefit |

|---|---|---|

| Internal Profile | Precision-ground square or hexagonal bore. | Provides maximum contact area and grip on the workpiece. |

| Material | Typically made of hardened alloy steel. | Ensures durability, wear resistance, and maintains clamping accuracy. |

| Clamping Method | Uses the standard ER system: the collet is pulled into the tapered chuck, causing it to compress uniformly. | Delivers even, concentric clamping force with excellent repeatability. |

| Standards | Manufactured to ER collet standards (e.g., ER32, ER40) and specific profile dimensions (e.g., 10mm hex, 1/2" square). | Guarantees interchangeability with standard ER tooling systems. |

These collets are specified using a combination of the ER size and the workpiece dimensions:

Example Naming: ER32 Hexagon 10mm or ER40 Square 1/2".

Meaning: This indicates an ER32 collet body with a 10mm hexagonal internal bore, or an ER40 body for clamping 1/2" (approx. 12.7mm) square stock.

Secondary Operations on CNC Lathes: This is the most common use. A piece of bar stock is first cut to length. The ER square/hex collet is then used in the lathe's turret or a secondary spindle to hold the pre-cut piece for machining additional features (drilling cross-holes, milling flats, engraving) without the need for a custom fixture.

Workholding on Machining Centers: They can be used in a vise or directly in the spindle of a milling machine to present square or hex stock at a precise, repeatable orientation for machining.

Key Advantages:

High Precision & Repeatability: Offers excellent concentricity and axial alignment, crucial for accurate machining.

Quick Changeover: Much faster than adjusting a standard vise with soft jaws.

Strong, Even Grip: The full-profile contact prevents workpiece rotation and distortion.

Space-Saving: A very compact workholding solution compared to bulky fixtures.

Workpiece Tolerance: The bar stock must have consistent dimensions. Collets are designed for a specific nominal size with a very small clamping range (typically less than 0.1mm/0.004"). Oversized or undersized stock will not clamp correctly.

Not for Round Stock: These collets cannot effectively clamp round material. A standard round-bore ER collet must be used for that purpose.

Chucking Pressure: Avoid excessive tightening force, as it can deform the collet's profile over time. Use the recommended torque for the ER nut size.