| Availability: | |

|---|---|

| Quantity: | |

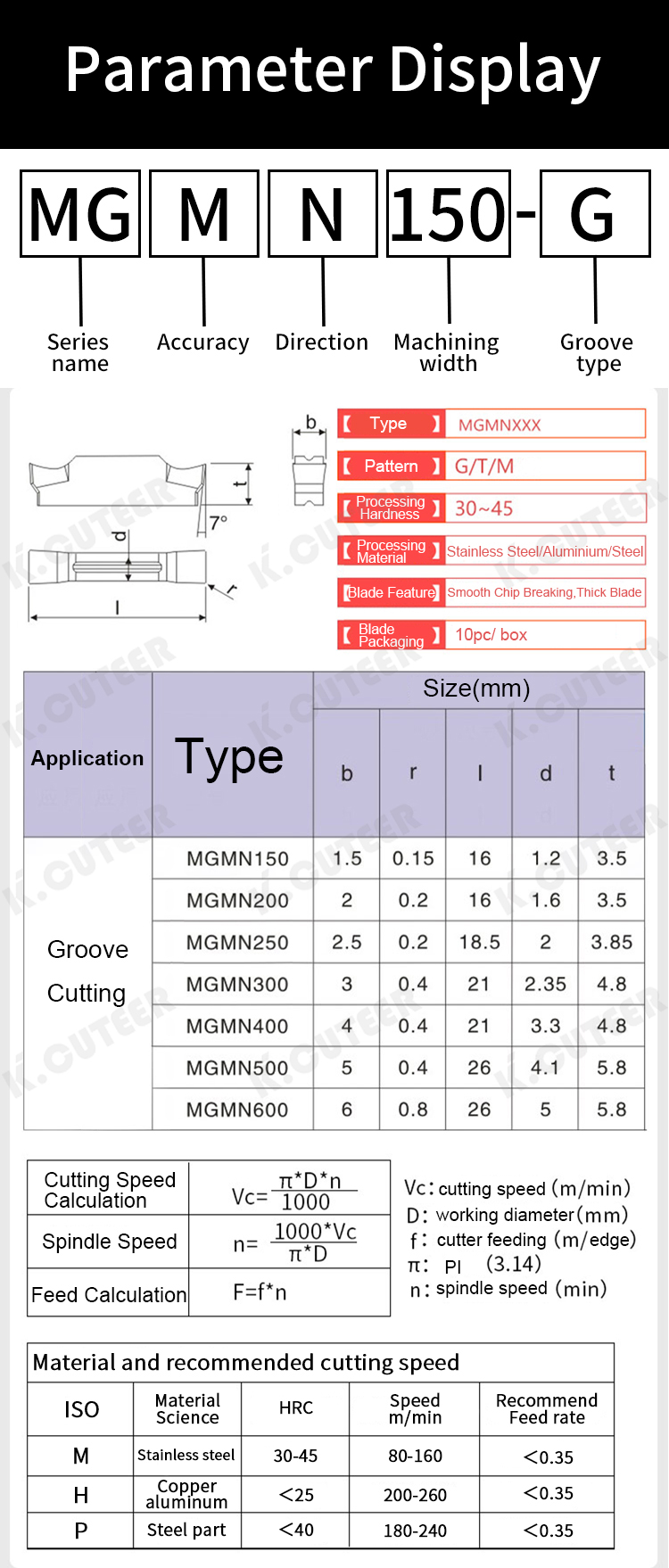

Specification:

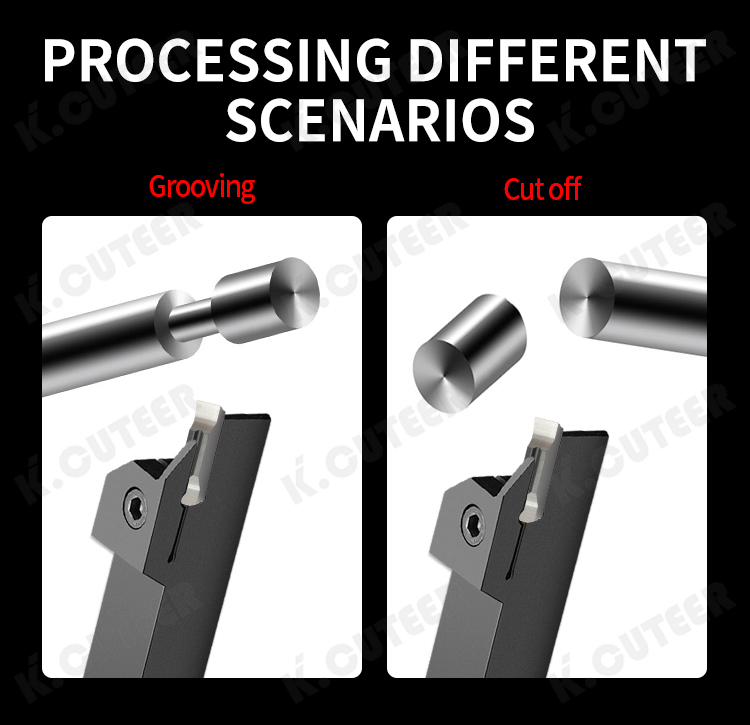

Name: Grooving and cutting CNC blade

Brand: KEENCUTEER

ItemNo.: MGMN

Suitable for: MGEHR/L

H01: For aluminum and copper parts processing.

LH: Large front angle design, low cutting resistance without generating chip lumps.

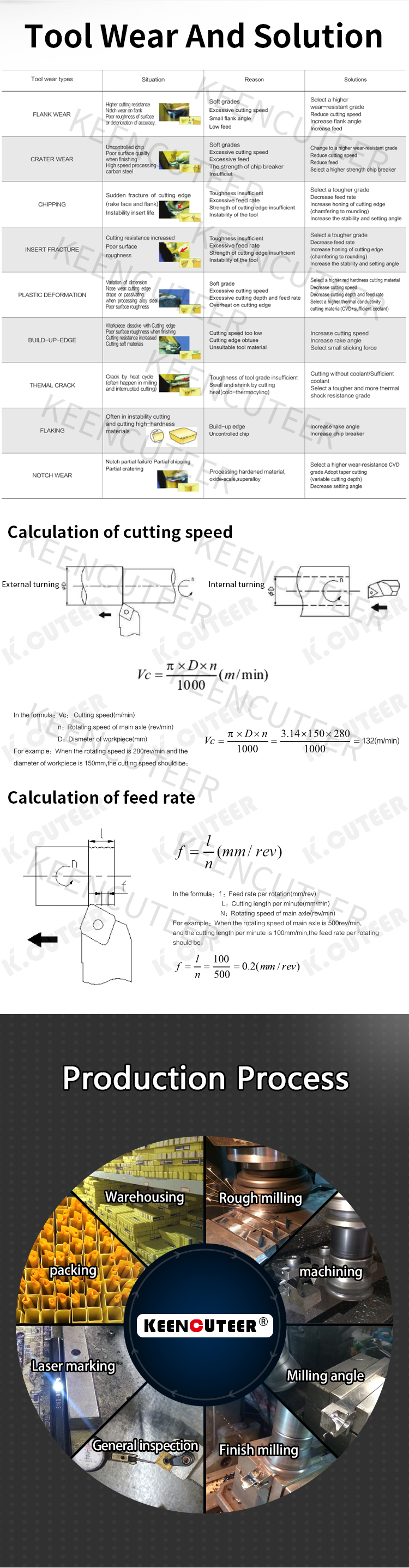

Features:

1. Reduces friction between chips and workpieces, resulting in better surface roughness.

2. Good chip removal, less likely to stick to the tool.

3. More wear-resistant, reduces tool replacement, and improves production efficiency.

Key Characteristics:

Grade: H01

Coating Technology: Features a unique Titanium Diboride (TiB₂) coating.

Primary Application: Optimized for the high-speed machining of aluminum alloys and other sticky, non-ferrous materials.

Core Advantage: The TiB₂ coating provides an extremely low coefficient of friction, which highly effectively prevents the formation of built-up edge (BUE). This results in superior surface finish, improved dimensional accuracy, and longer tool life.

Insert Geometry (MGGN): The MGGN designation typically refers to a negative rake, square-shaped insert with a sharp cutting edge and generous chip pockets, promoting free cutting and efficient chip evacuation in aluminum.

In summary, the MGGN H01 insert combines a sharp geometry with a non-stick TiB₂ coating, making it an excellent solution for productive and high-quality aluminum machining.