| Availability: | |

|---|---|

| Quantity: | |

TCMT Insert for Steel Turning

English Introduction:

A TCMT insert is a specific type of indexable carbide turning insert widely used in machining operations, particularly for machining steel workpieces .

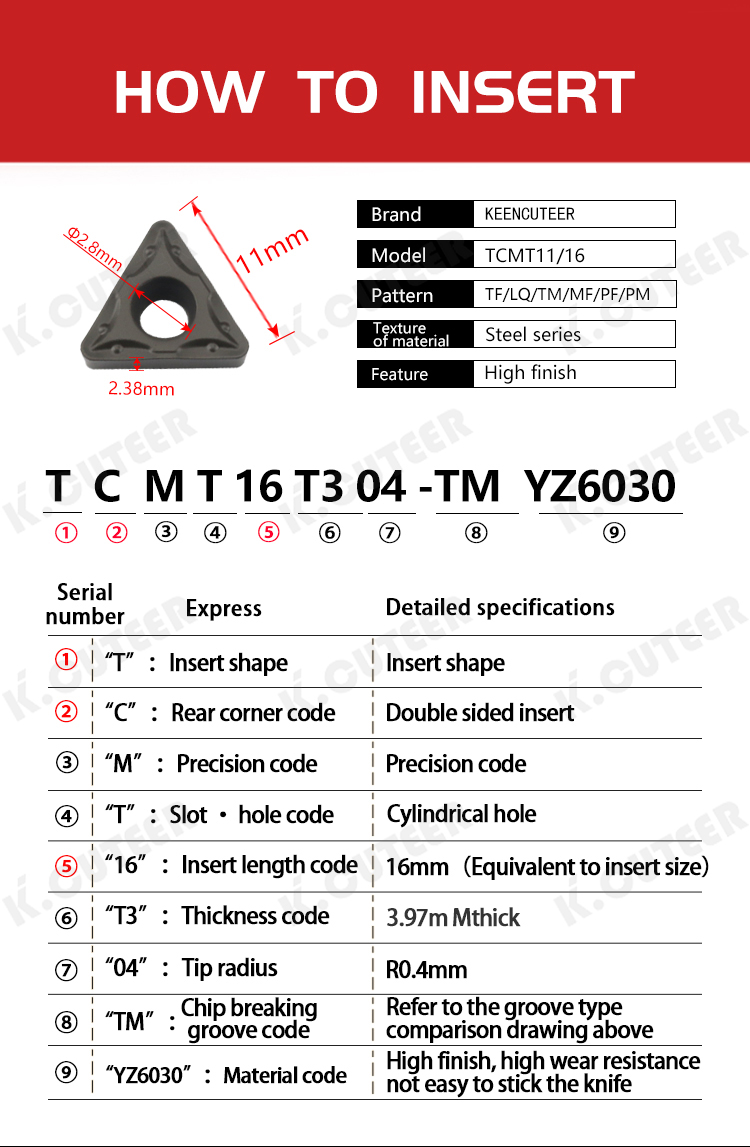

Shape and Angles: The "T" indicates a triangular shape (60-degree corner angle) . This shape provides three cutting edges per indexable side (and since it's typically double-sided, you get six edges total), making it a cost-effective option.

Clearance Angle: The "C" signifies a 7-degree clearance angle. This positive clearance angle helps reduce cutting forces and power consumption, leading to a freer cutting action suitable for a wide range of steel grades.

Tolerance Class: The "M" stands for the tolerance class, ensuring dimensional consistency for reliable performance.

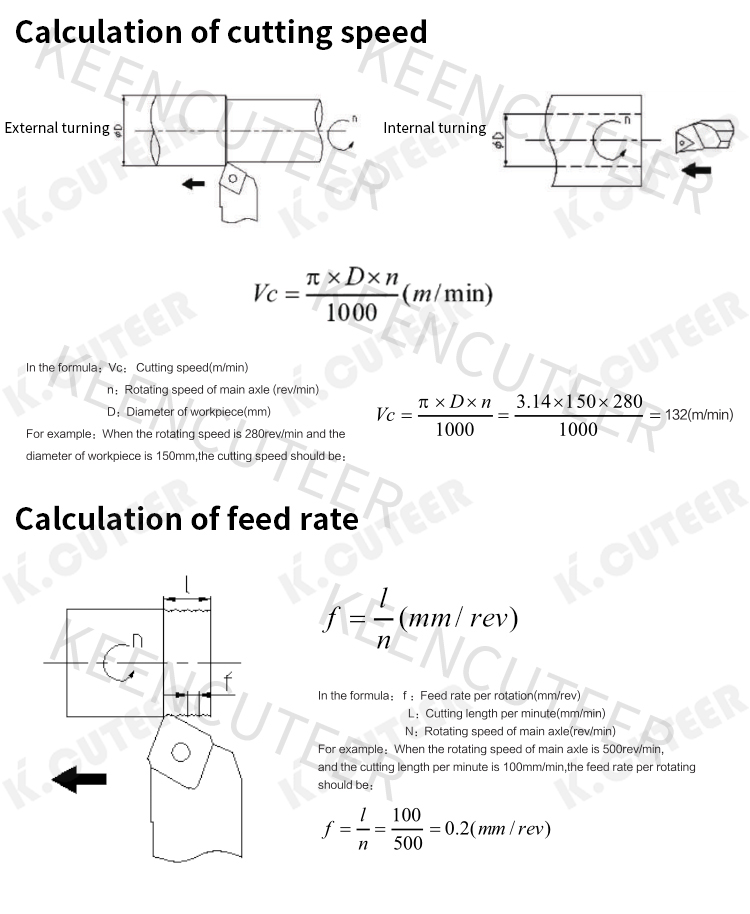

Size and Nose Radius: The following numbers (e.g., 16T308) specify the insert size (inscribed circle, thickness) and the nose radius (e.g., 0.8 mm) . A larger nose radius can improve tool life and surface finish but may increase cutting forces.

Difference

YZ6030:High hardness, used for processing steel parts below 45 degrees.

YZ5010:For machining any superhard material, suitable for 40-60 degrees.

YZ5028:Strong interrupted machining, used for processing 20-60 degrees steel parts.

JC800:With high quality material coating,Used for processing steel parts.

Key Features & Applications:

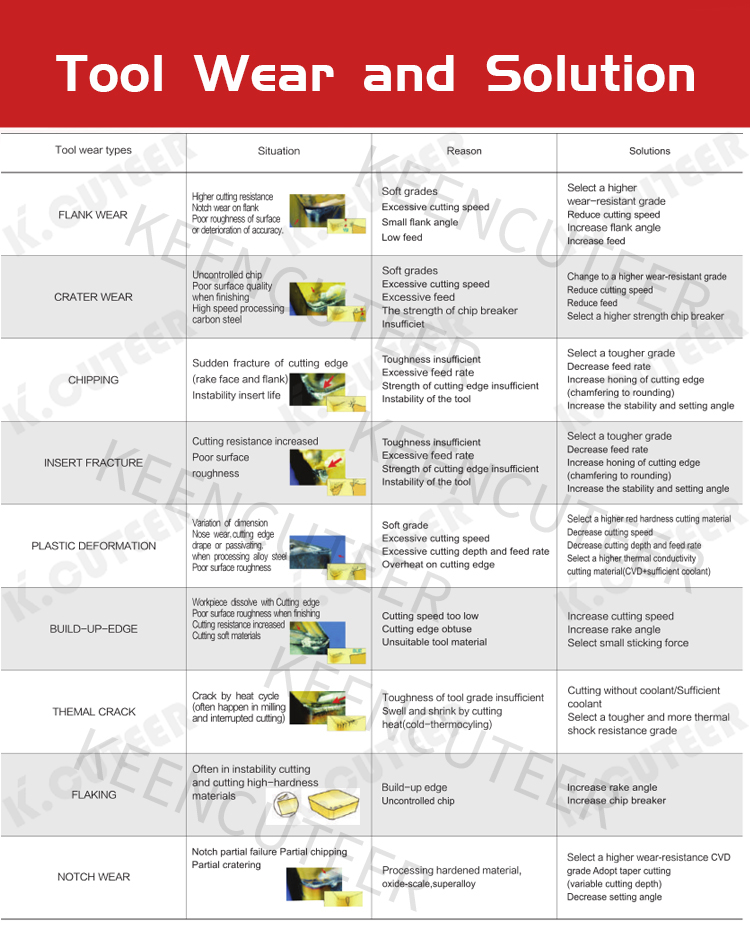

1.Positive Rake Geometry: TCMT inserts are positive rake inserts . This geometry results in lower cutting forces, reduced heat generation, and improved surface finishes compared to negative rake inserts. This makes them particularly well-suited for finishing and semi-finishing operations on steels .

2.Chipbreaker Design: The final letter(s) (e.g., MP, FP, LF) denote the chipbreaker groove design . These grooves are engineered to control chip formation effectively. For steel machining, common chipbreaker types include:

1)Finishing (e.g., F, LF): Designed for light cuts and fine feeds, producing small, easily broken chips.

2)General Purpose/Medium (e.g., M, MP): A balance between finishing and roughing capabilities, offering good chip control across a wider range of feeds and depths of cut.

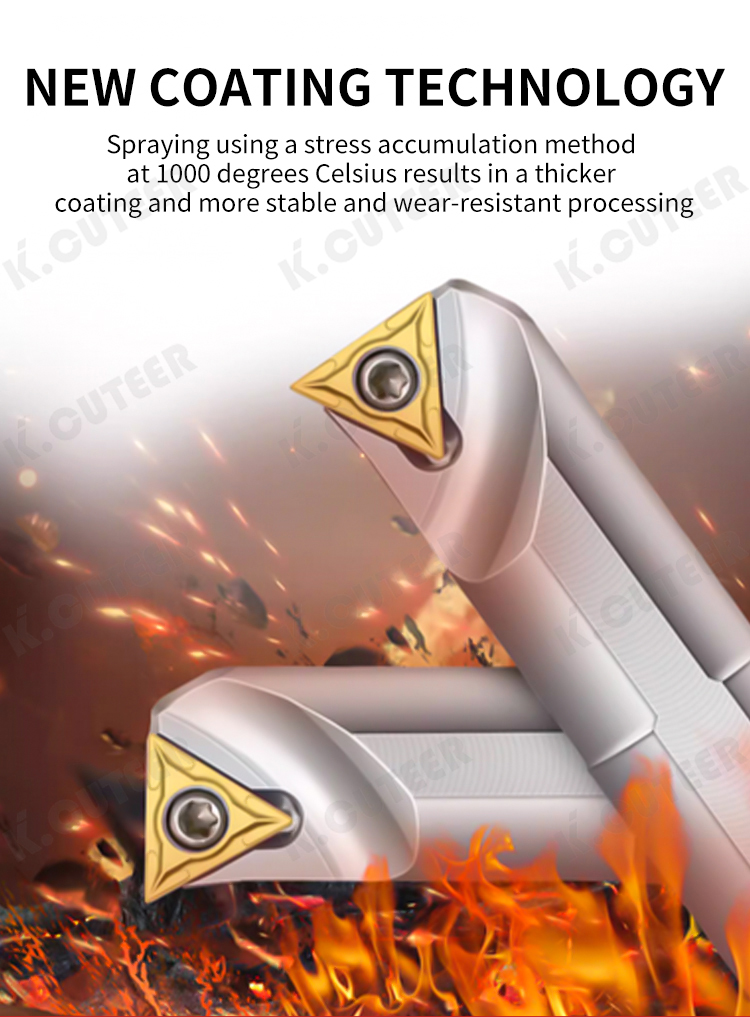

3.Carbide Grades and Coatings: For steel machining, these inserts are typically made from carbide substrates coated with advanced materials like PVD or CVD coatings (e.g., TiN, TiCN, Al₂O₃) . These coatings significantly enhance wear resistance, thermal stability, and overall tool life. Specific grades are often developed for different steel types, from low-carbon steels to more challenging alloy steels .

Primary Application Advantages:

1.Excellent Chip Control: Effective chipbreaking prevents long, tangled chips that can damage the workpiece or toolholder.

2.Good Surface Finish: The positive geometry and sharp cutting edges are conducive to achieving fine surface finishes.

3.Versatility: With the right grade and chipbreaker selection, TCMT inserts can handle a wide range of steel materials and operating conditions, from continuous finishing to lightly interrupted cuts .

4.Cost-Effectiveness: The multiple cutting edges per insert lower the cost per edge.