| Availability: | |

|---|---|

| Quantity: | |

Specification:

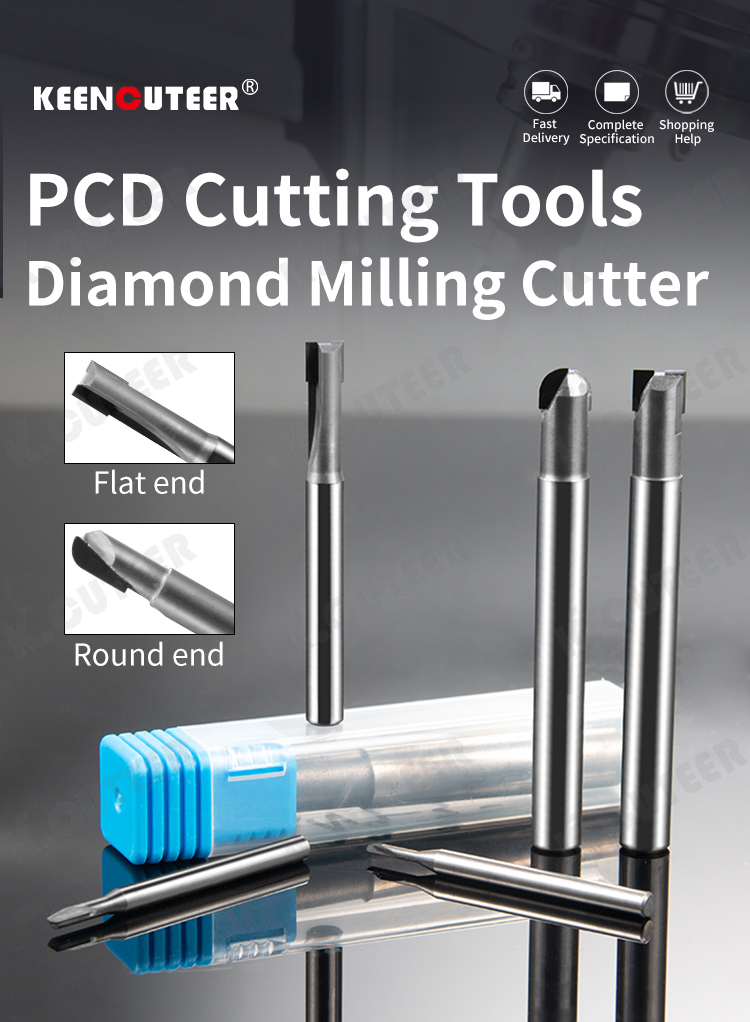

Product Name: PCD Diamond Milling Cutter

Product material: Tungsten steel blade body PCD blade head

Tolerance: plus or minus 0.02~0.03mm

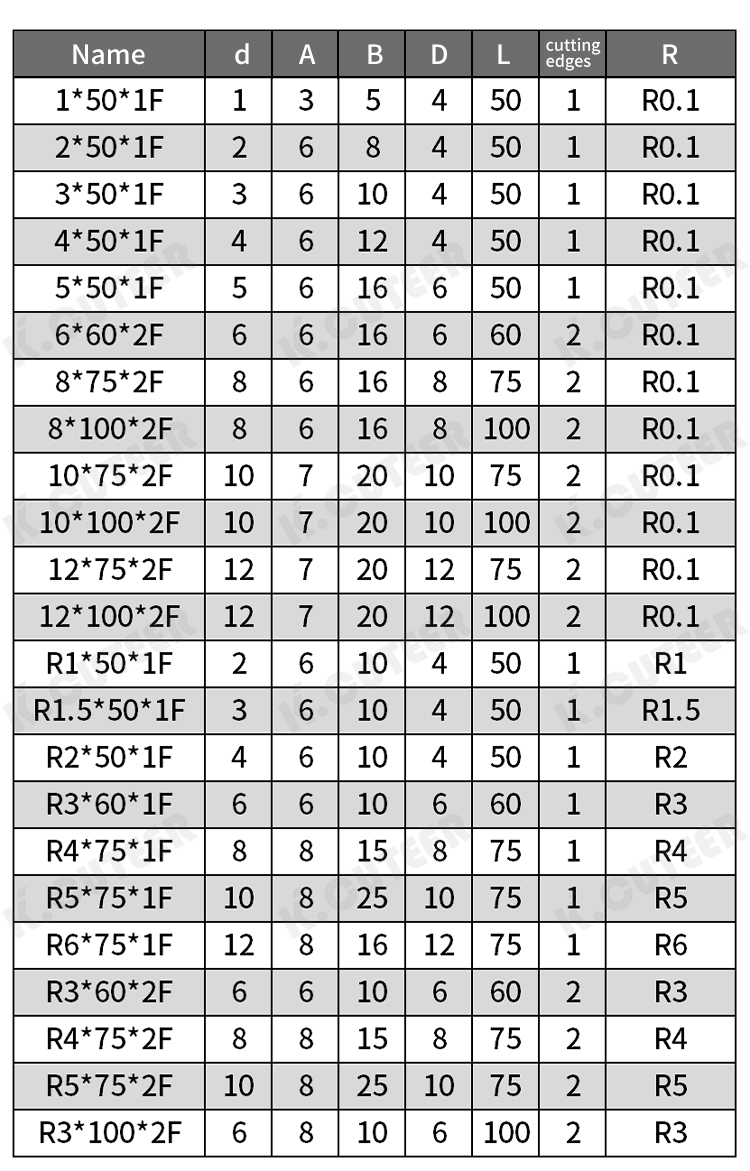

Blade diameter range: 1-12mm

Length range: 50~100mm

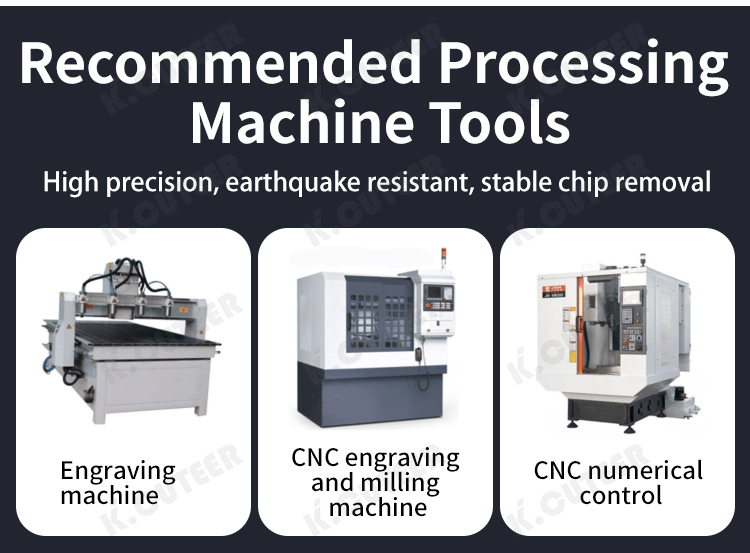

Applicable machine tools: CNC machining centers, engraving machines, precision engraving machines, etc

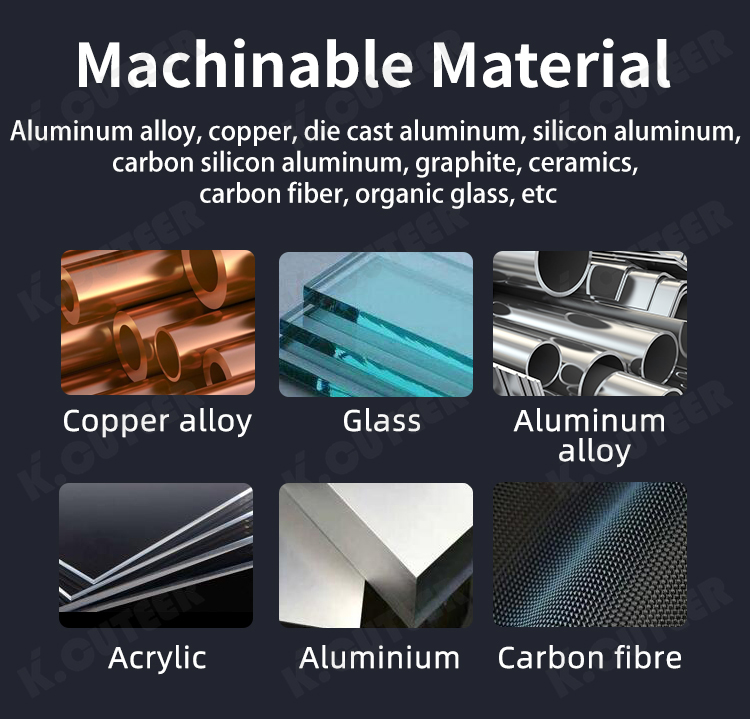

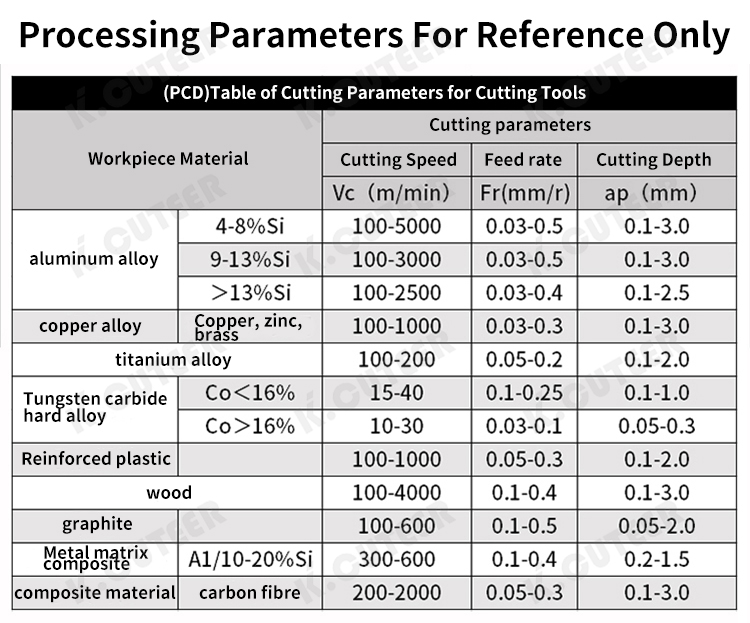

Applicable materials: aluminum alloy, copper, die cast aluminum, silicon aluminum, carbon silicon aluminum, graphite, ceramics, carbon fiber, organic glass, etc

Feature :

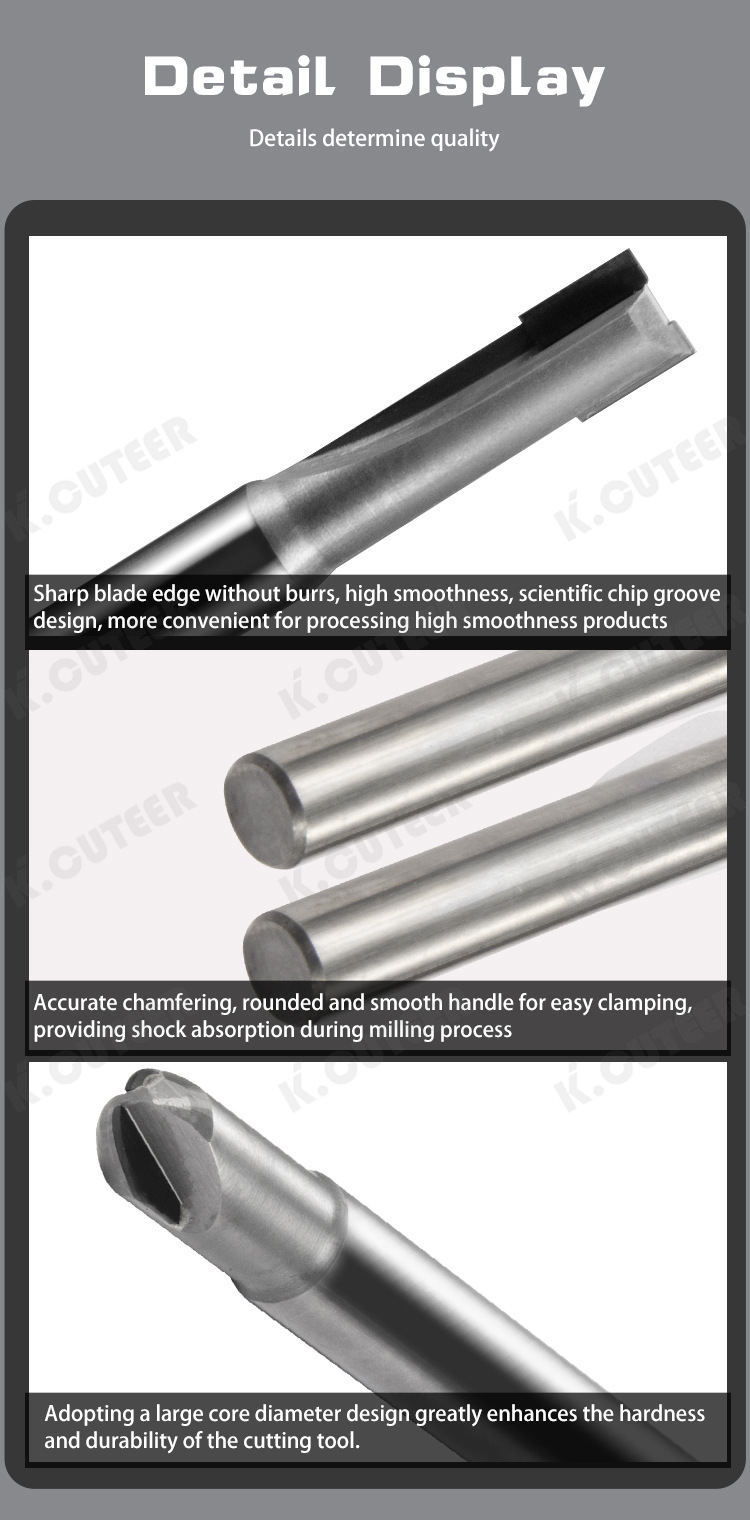

1. The tungsten steel blade body has stable performance, is not prone to overheating, and reduces the number of tool changes.

2. Diamond cutting heads have high hardness, strong wear resistance, and long service life.

3. Good chip removal, non stick to the blade.

4.Extreme Hardness & Wear Resistance: The PCD tip consists of countless fine diamond grains sintered together, making it one of the hardest materials available. This grants it wear resistance tens or even hundreds of times greater than cemented carbide, drastically reducing tool changes.

5.High-Speed Machining Capability: PCD cutters can withstand very high cutting speeds, significantly boosting machining efficiency and productivity.

6.Superior Surface Finish: The sharp edge and excellent wear characteristics of PCD enable it to produce high-quality surface finishes, often eliminating the need for subsequent finishing operations.

7.Chemical Stability: PCD is inert to most materials, minimizing reactions like adhesion or diffusion wear during cutting.

Limitations:

Cost: PCD tools are more expensive than carbide tools.

Machinability: The extreme hardness makes the PCD tip difficult to grind and shape, requiring specialized manufacturing processes.

Material Restrictions: Unsuitable for machining ferrous metals (steel, iron) due to a chemical reaction that causes rapid diamond graphitization and tool failure at high temperatures.

Primary Applications:

PCD milling cutters are predominantly used for machining:

Non-ferrous Metals: Such as silicon-aluminum alloys, high-silicon aluminum, copper alloys, and other abrasive materials common in the automotive and aerospace industries.

Non-metallic Materials: Including carbon fiber reinforced plastics (CFRP), fiberglass, ceramics, graphite, and various composite materials.

Woodworking & Plastics: For specialized applications requiring extreme durability.

In summary, the PCD milling cutter is a premium, high-performance tool ideal for achieving high efficiency, exceptional finish quality, and maximum cost-effectiveness in long-run production of abrasive non-ferrous and non-metallic components.