| Availability: | |

|---|---|

| Quantity: | |

3D Mold & Die Machining: Finishing cores, cavities, and intricate details.

Aerospace Components: Machining complex impellers, turbine blades, and structural parts.

General 3D Contouring: Creating smooth radii, free-form surfaces, and decorative engravings.

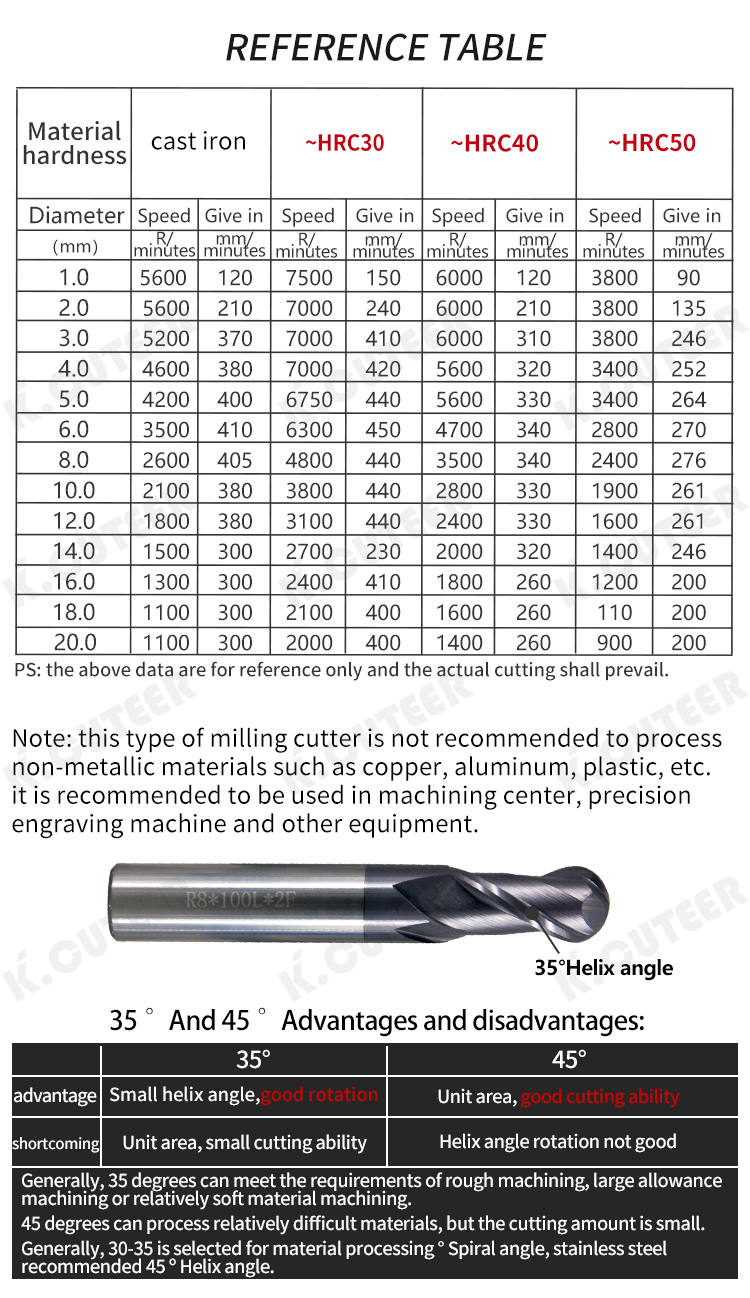

Cutting Strategy: Primarily used for contour parallel or z-level finishing paths. A small stepover (5%-10% of tool diameter) is critical for achieving a smooth surface finish with minimal cusp height.

Critical Parameters: Feed per tooth and axial depth of cut must be balanced. A light axial depth is used to maintain tool life and prevent deflection. For hardened steels (HRC 45-55), a conservative starting parameter would be a surface speed (Vc) of 120-150 m/min and a feed per tooth (fz) of 0.03-0.06 mm/tooth.

Tool Path Optimization: Employ corner radius compensation or smoothing algorithms in your CAM software to maintain constant tool engagement and feed rate, preventing tool marks during direction changes.

System Rigidity: Non-negotiable. Use a high-precision, centric collet chuck (e.g., hydraulic or shrink-fit) to maximize holding force and minimize runout, which directly translates to better surface quality and tool life.

Coolant Strategy: For finishing, a mist coolant or high-pressure through-tool coolant is highly effective for chip evacuation and temperature control, especially in deep cavities.