| Availability: | |

|---|---|

| Quantity: | |

Product Description:

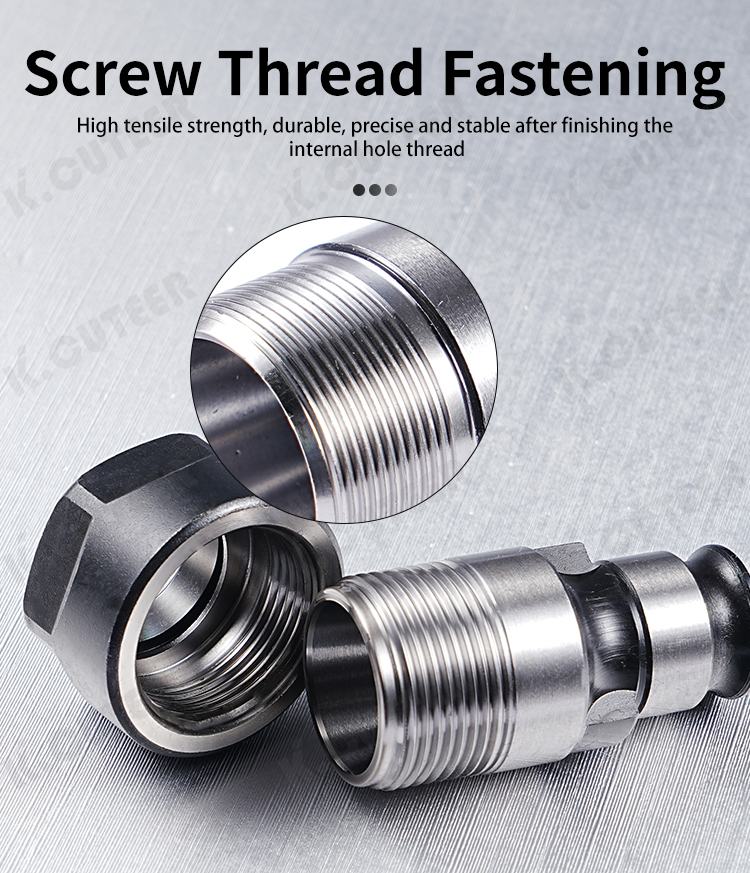

A tapping chuck, also known as a tap holder, is a core component on a tapping machine, specifically designed for clamping taps to perform internal thread machining with high precision and efficiency.

Unlike standard drill chucks, a tapping chuck typically features a critical characteristic—float compensation. During the tapping process, there is a minute discrepancy between the machine spindle's feed and the actual pitch required by the tap. The floating mechanism within the chuck automatically compensates for this error through axial spring action. This effectively prevents tap breakage, thread stripping, or hole size inaccuracies caused by lead inaccuracies.

Furthermore, high-quality tapping chucks often incorporate a quick-change feature, allowing operators to install and release taps rapidly without additional tools, significantly boosting productivity. They are also engineered to provide high concentricity and excellent torque transmission, ensuring the tap rotates stably to produce high-quality threads.

Features:

1.Float Compensation: Automatically compensates for feed error, protecting both the tap and the workpiece.

2.High Precision: Ensures high concentricity between the tap and spindle for superior thread quality.

3.Quick-Change: Enhances operational efficiency and simplifies the process.

4.Robust & Durable: Capable of withstanding the high torque and impact forces generated during tapping.

In conclusion, the tapping chuck is an indispensable tool in modern precision threading operations. Its performance directly impacts machining efficiency, product quality, and tool life.