| Availability: | |

|---|---|

| Quantity: | |

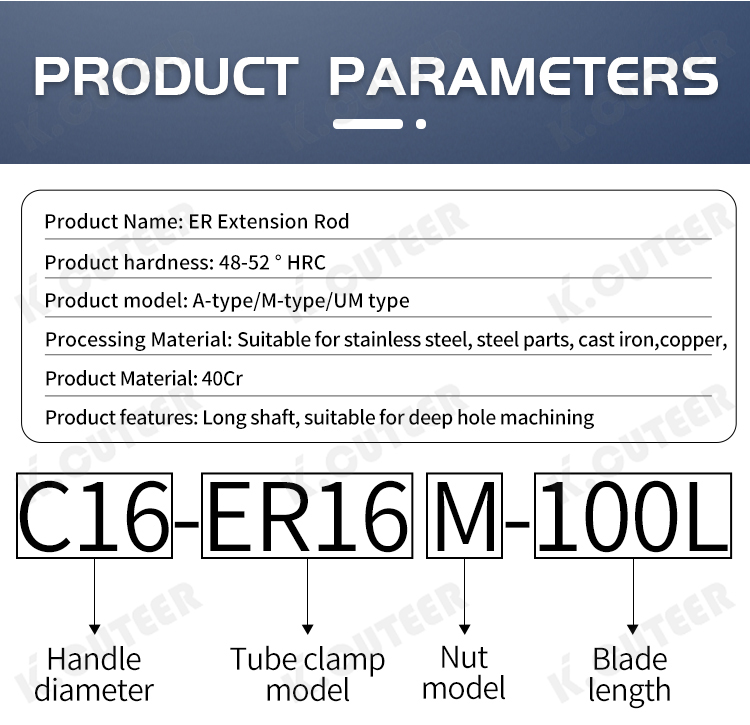

The name follows a common industry shorthand:

C: This part of the model number indicates the machine-side taper or shank interface of the extension rod. In the case of C20, it likely refers to a CAT/CV toolholder taper with a size of 20 (e.g., CAT40 taper), which is a standard interface for CNC milling machines.

ER: Indicates the working end of the rod holds a standard ER collet chuck.

Numbers (e.g., 16): This typically refers to the maximum collet size the holder can accept. An ER16 collet holder accepts ER16 series collets.

Based on a common example model (C20-ER16M-150L), here are the typical specifications:

| Feature | Specification | Notes |

|---|---|---|

| Material | Alloy Steel (e.g., 20CrMnTi) | Provides strength and durability. |

| Hardness | HRC 44-48 | Hardened to resist wear from the collet nut and use. |

| Accuracy (Runout) | ~0.003 mm | Crucial for maintaining precision in the extended tool setup. |

| Length Code (e.g., 150L) | 150 mm extension length | Actual added reach depends on the specific model. |

Assembly: The machine-side taper (C20) is inserted into your machine's spindle. An ER collet and locking nut are assembled onto the ER end of the rod.

Tool Mounting: Your cutting tool (drill, end mill) is inserted into the collet, and the nut is tightened to clamp it securely.

Machining: The extended tool can then reach into deeper or obstructed areas of the workpiece for operations like milling, drilling, or reaming.

ER extension rods are a modular, cost-effective solution ideal for general applications. For maximum performance in demanding situations (like high-speed machining or hard-to-reach areas), major tooling brands offer specialized integrated systems. For example, SCHUNK's SVL series extension rods are designed with minimal interference contours and can be paired with hydraulic or shrink-fit chucks for superior vibration damping.

Reduced Rigidity: Any extension increases the tool's overhang, which reduces rigidity. This can lead to vibration (chatter), poorer surface finish, and reduced tool life.

Speed Limits: Always adhere to the manufacturer's maximum RPM rating.

Balancing: For high-speed applications, dynamically balanced extension rods are recommended.

Tool Selection: Use the shortest possible extension and the most rigid cutting tool to minimize negative effects.