| Availability: | |

|---|---|

| Quantity: | |

The bar puller is mounted on the lathe's turret like a cutting tool. A typical cycle is:

Cut-Off: A part is completed and cut off from the bar stock.

Positioning: The turret indexes the bar puller into position, and it moves to grip the exposed end of the remaining bar.

Pulling & Clamping: The puller's jaws close to grip the bar. The lathe's chuck opens, and the puller moves axially to pull the bar out to the exact length required for the next part.

Re-clamping & Release: The lathe chuck closes to clamp the bar again. The puller's jaws open and retract, ready for the next cycle.

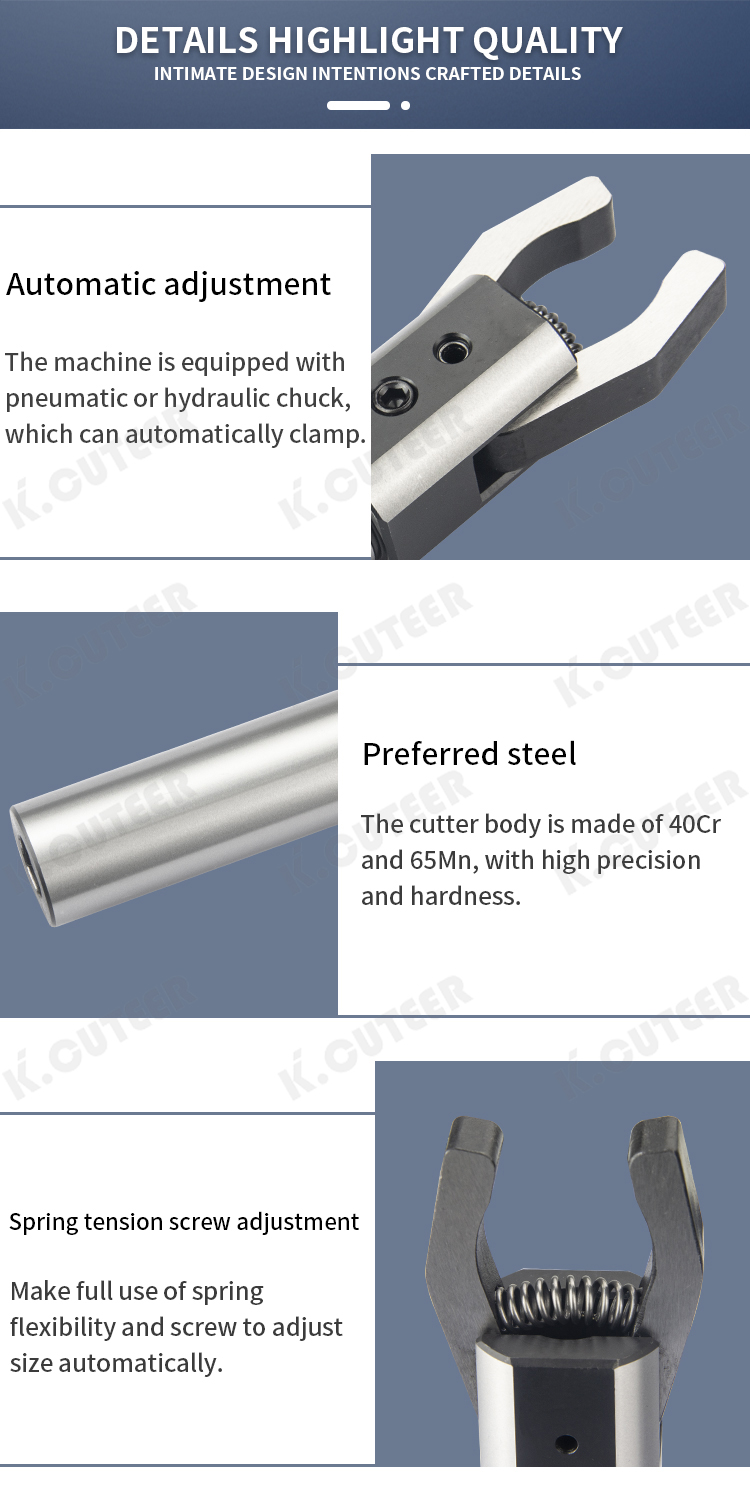

Key components are hardened gripping jaws (often with serrated or knurled surfaces) and an actuation mechanism.

There are two primary designs, differing in their actuation method:

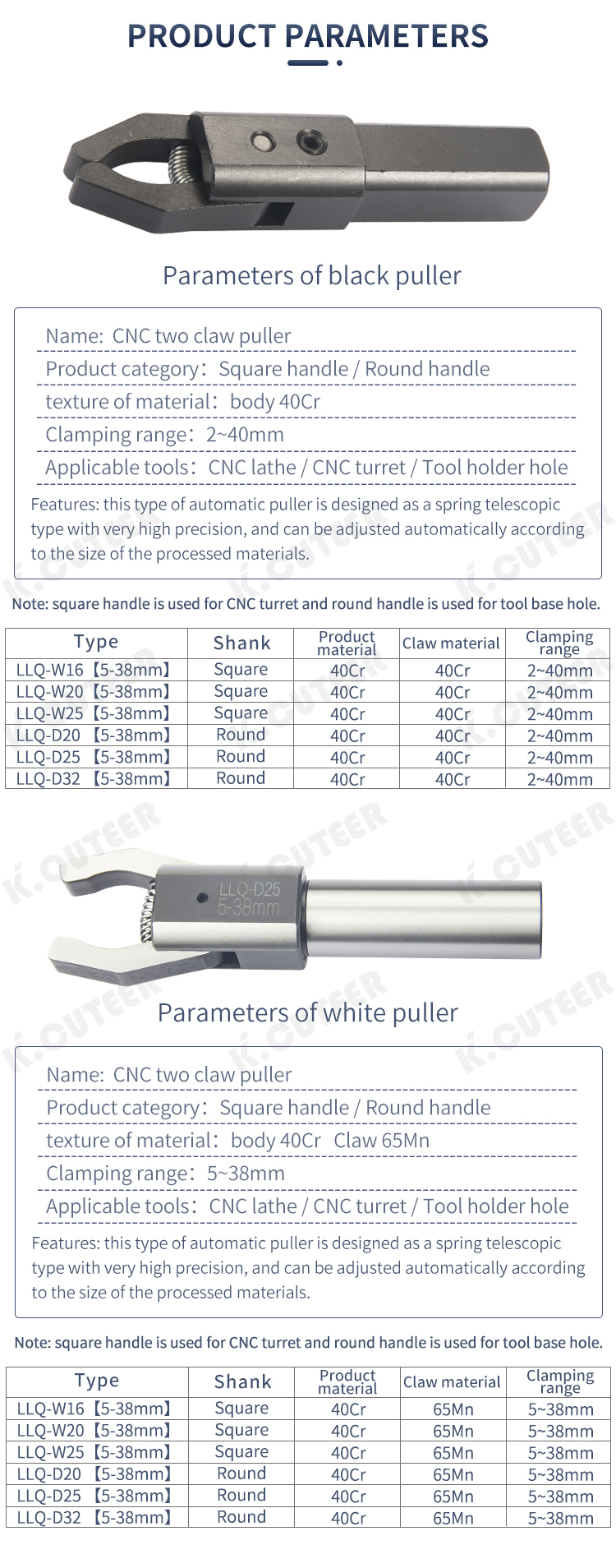

| Type | Working Principle | Key Features |

|---|---|---|

| Mechanical (Swing Arm) Bar Puller | Uses a hard stop on the machine bed. The turret feeds the tool forward; the puller's arm contacts the stop, causing it to pivot and close the jaws around the bar. | Simple, robust, cost-effective. Requires a fixed mechanical stop setup. |

| Hydraulic Bar Puller | Uses hydraulic pressure from the machine's turret or an external unit to close the jaws. Activated by an M-code (e.g., M11/M10). | More precise, versatile. Can grip on any surface (even machined diameters), offers adjustable gripping force. No hard stop needed. |

Bar Stock Tolerance: For consistent pulling length, the bar stock diameter must be uniform. Hydraulic pullers are more forgiving.

Gripping Force: Must be sufficient to pull the bar against the resistance of the guide bushing or chuck without slipping or marring the material.

Interference: The puller's body must clear the chuck, guide bushing, and other components during rotation and movement.

Programming: Requires specific G-codes and M-codes (for hydraulic types) integrated into the part program's cycle.

It is crucial to distinguish a Bar Puller from a Bar Pusher or Bar Support:

Bar Puller: Pulls the bar out of the spindle (used with a bar feeder for sequential part machining).

Bar Pusher/Pushrod: Pushes a short bar into the spindle from the rear (used for machining single short pieces without a feeder).

Bar Support (Steady Rest): Supports a long, overhanging bar to prevent whipping during rotation, but does not pull it.

This device is fundamental to automated turning production. If you are setting up a lathe for bar work, specifying the bar diameter range and machine model (to determine turret compatibility) is essential for selecting the correct puller type and size.