| Availability: | |

|---|---|

| Quantity: | |

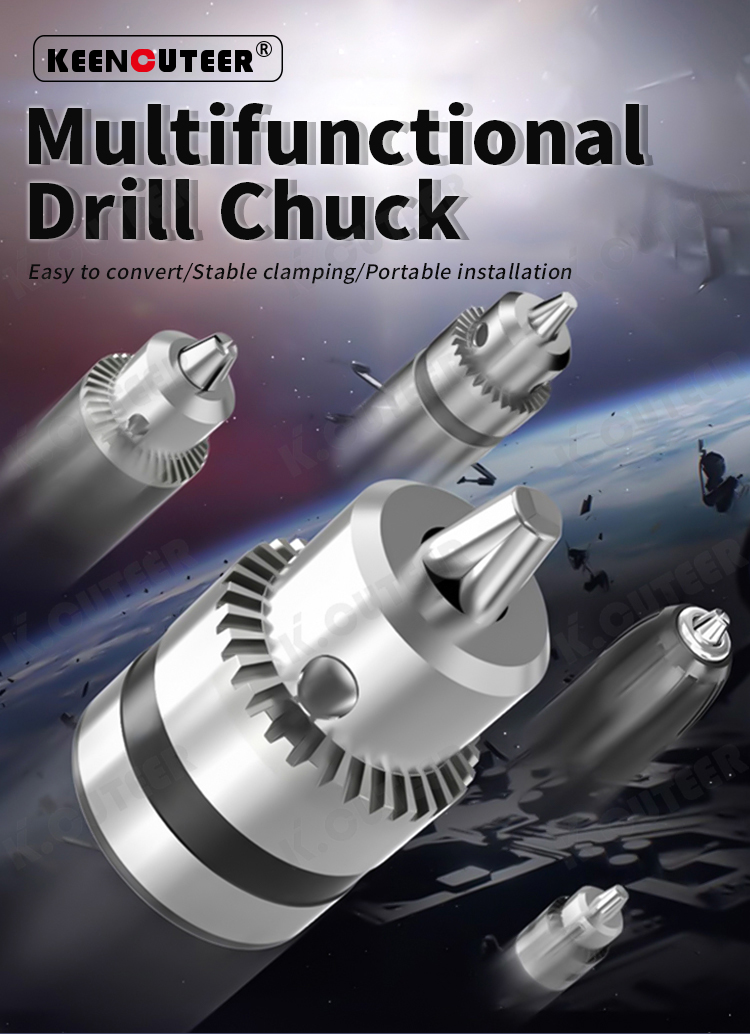

Key Features & Benefits

Integrated Multi-Function Design: This chuck uniquely combines several tool types—most commonly a drilling function with a milling function—within one compact unit. Some advanced models may also integrate tapping or even boring capabilities.

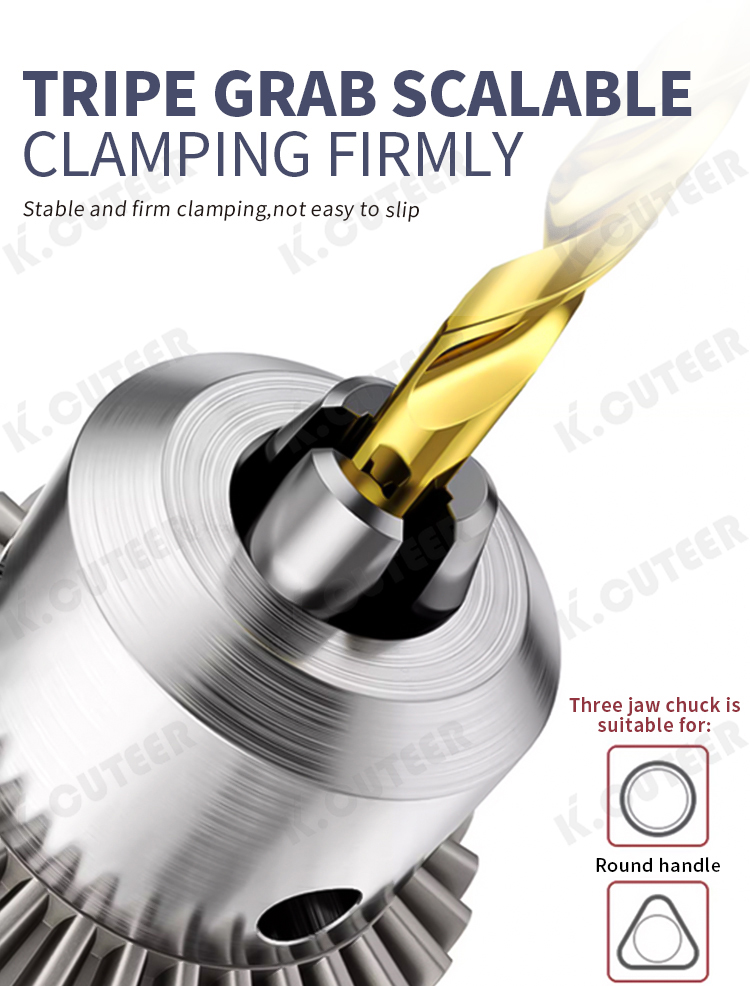

Reduced Tool Changes: The primary advantage is the drastic reduction in tool change times. A single multi-function chuck can perform operations like drilling, spot facing, chamfering, and light milling, which would otherwise require multiple dedicated tools.

Improved Accuracy and Efficiency: By minimizing setup changes and re-clamping of the workpiece, it improves positional accuracy and overall machining efficiency. This leads to shorter cycle times and increased throughput.

Space-Saving: It saves critical space on the tool magazine of a CNC machining center, allowing for a wider range of other tools to be available for a job.

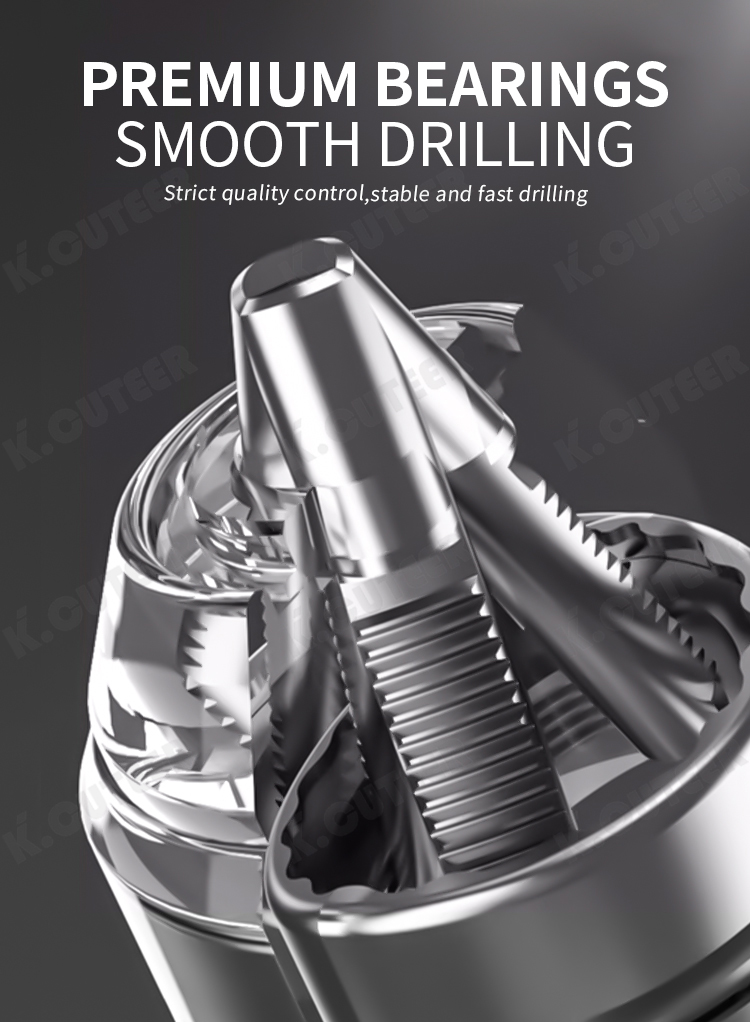

High Rigidity: Engineered for high rigidity to handle the combined forces of drilling and milling, ensuring stability and precision during operation.

Common Applications

The Multi-Function Drill Chuck is ideal for complex parts requiring sequential operations on a single machine, such as:

Drilling a hole and immediately milling a surrounding face or pocket.

Drilling and then chamfering the hole edge in the same setup.

Producing components with multiple features in high-volume manufacturing where cycle time is critical.

Typical Configuration

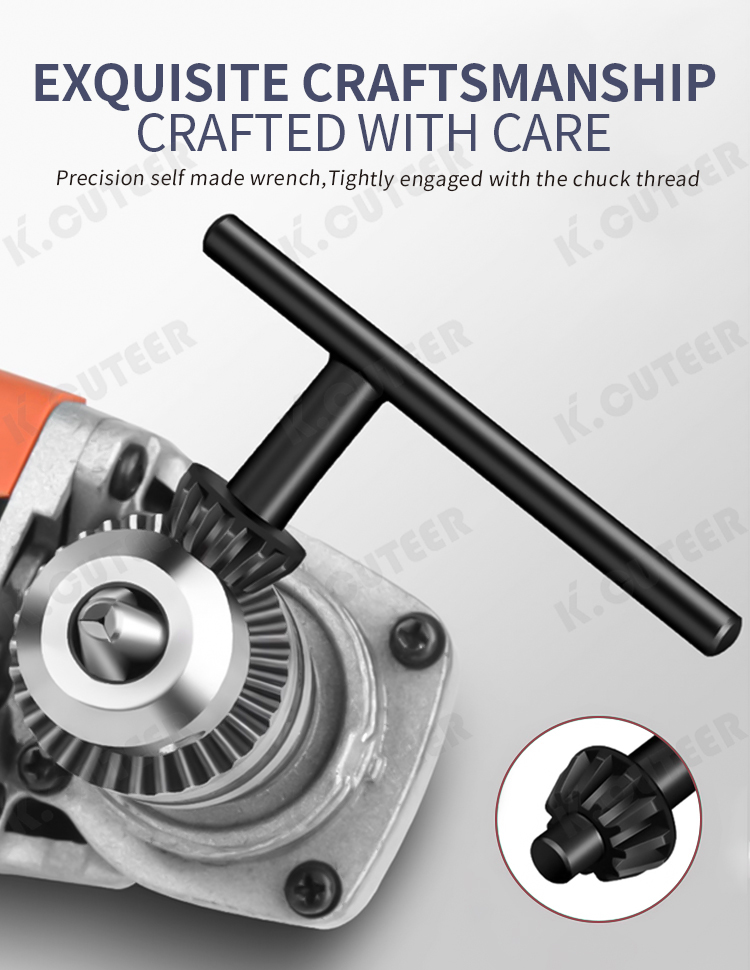

These chucks often feature a modular design, with a central drilling unit (e.g., a collet mechanism for a drill) surrounded by milling inserts or blades on the outer body.

They are typically mounted on machining centers using standard tapers like BT, CAT, or HSK.