| Availability: | |

|---|---|

| Quantity: | |

English Introduction:

The MGMN is a widely used insert geometry for grooving and cut-off operations. The JC700 is a specialized substrate and coating grade engineered by ISCAR specifically for high-productivity machining of carbon and alloy steels.

Specification:

Name: Grooving and cutting CNC blade

Brand: KEENCUTEER

ItemNo.: MGMN

Suitable for: MGEHR/L

JC700: upgraded version of JC600,Used for processing steel parts.

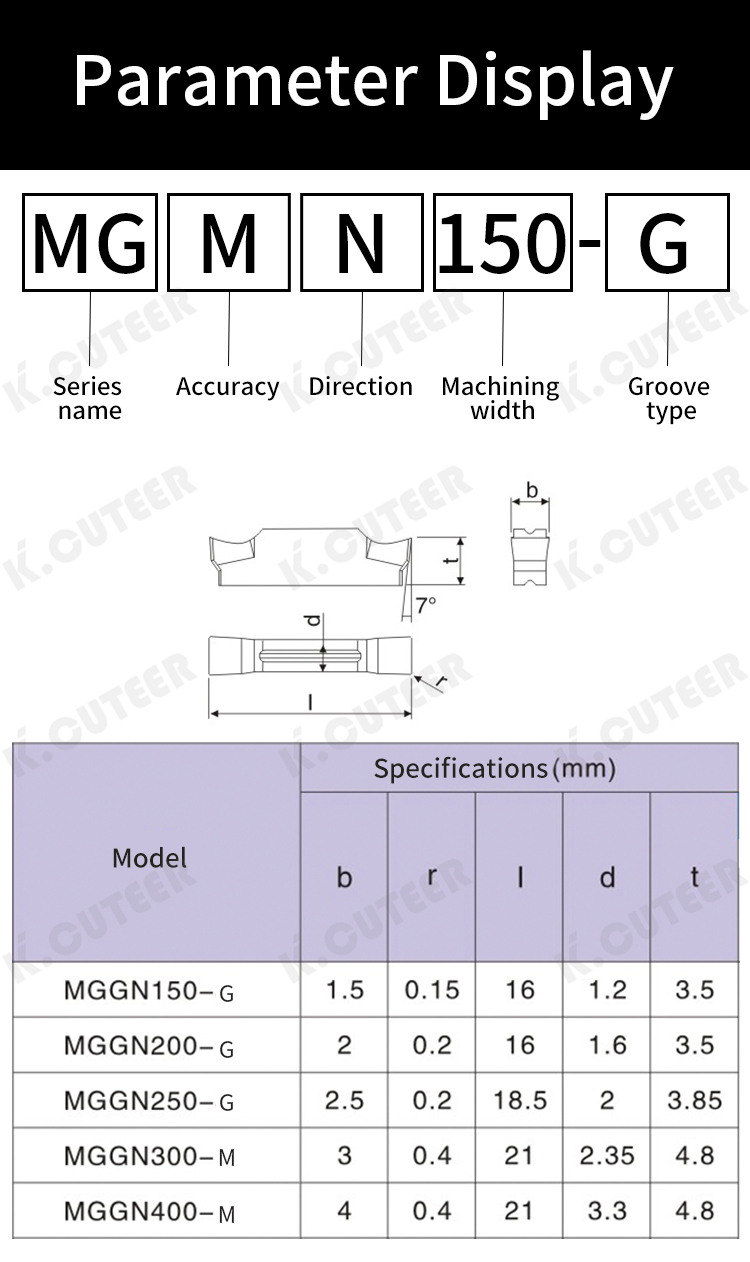

1. Insert Geometry (MGMN)

1)The MGMN code denotes a square-shaped, negative rake insert with a specific clamping hole design.

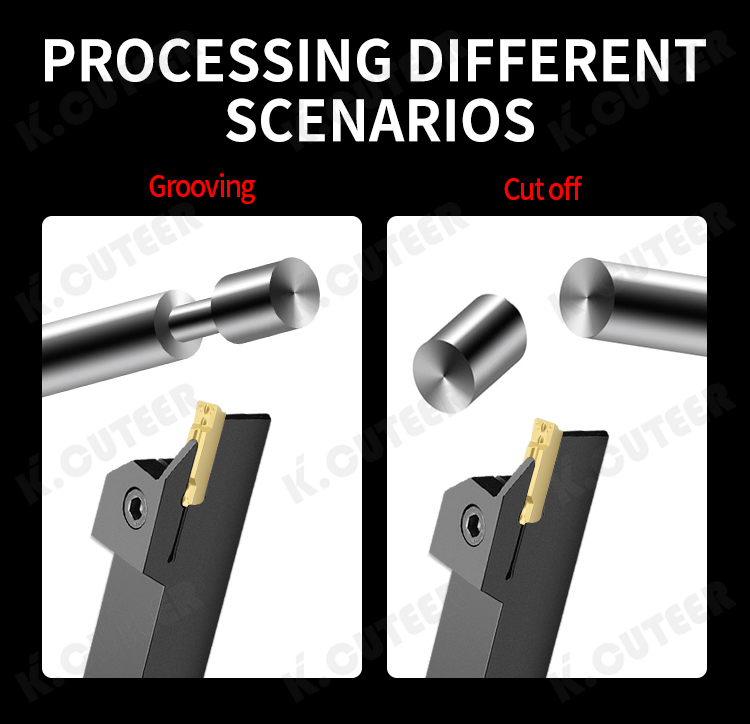

2)It is a versatile insert used for:

①Grooving

②Cut-off (parting)

③Light side-turning (copying)

3)The "M" typically indicates a tolerance class suitable for precision machining.

2. Grade (JC700)

1)JC700 is a premium grade from ISCAR's SUMO TEC coated grade family.

2)It features a micro-grain carbide substrate with a specialized CVD coating and a post-treatment technology that provides a smooth, crack-free surface.

3)This combination is specifically optimized to handle the abrasive nature and continuous cutting forces in:

①Carbon and Alloy Steels

②Cast Iron

③Stainless Steels (certain types)

3. Key Advantages

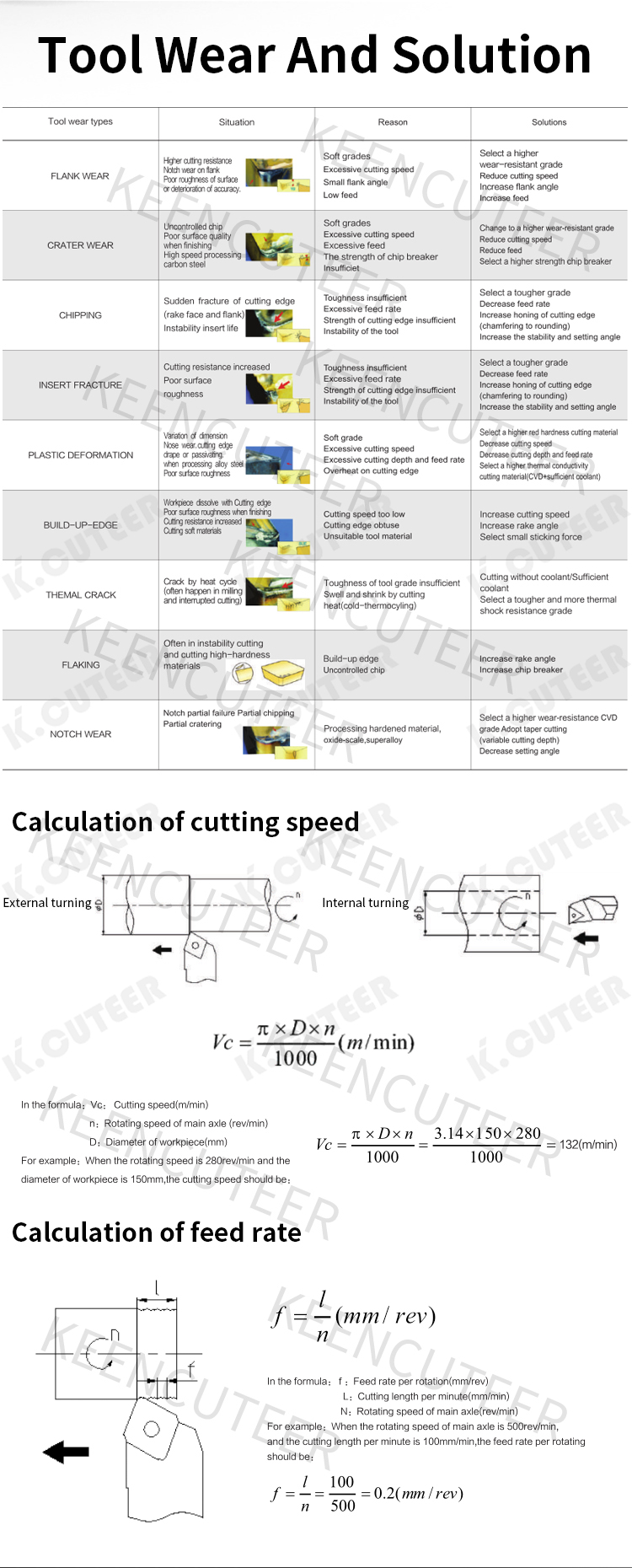

1)Superior Wear Resistance: The advanced CVD coating provides exceptional resistance to abrasive wear, leading to long and predictable tool life in steel machining.

2)Good Edge Toughness: The robust substrate and edge preparation make the insert resistant to chipping and suitable for applications with light interruptions or variations in material hardness.

3)High Productivity: The grade is designed for high-speed and high-feedrate machining, significantly reducing cycle times in mass production.

4)Versatile Application: While optimized for steel, its balanced properties make it a reliable choice for a wide range of general purpose grooving applications.

4. Applications

This insert is ideal for:

1)High-speed grooving and cut-off operations on steel shafts and components.

2)Machining components for the automotive, general machinery, and mold-making industries.

3)Production environments where maximizing metal removal rate and tool life are critical.

In summary, the MGMN JC700 insert combines a versatile grooving geometry with a wear-resistant, tough grade specifically designed for efficient and reliable machining of steel components.