| Availability: | |

|---|---|

| Quantity: | |

Key Features

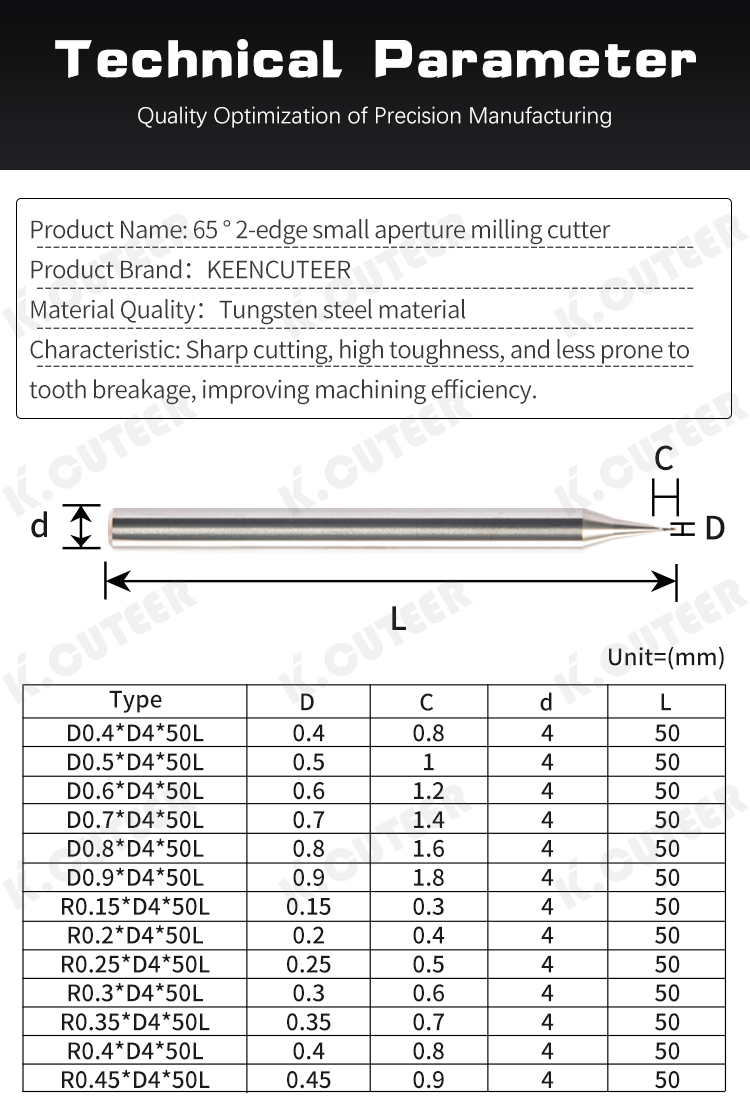

Extremely High Precision: The tools themselves are manufactured to micron-level tolerances to ensure the dimensional accuracy of machined features.

Exceptional Rigidity: To resist cutting forces and prevent breakage at such small scales, they are typically made from micro-grain carbide or powder metallurgy high-speed steel (PM-HSS). They are often coated with wear-resistant coatings (e.g., TiAlN, Diamond-DLC).

Specialized Geometry: Cutting edges are specially strengthened, and core diameters are optimized (e.g., with a variable core design) to achieve the best balance between chip flute space and rigidity. Two-flute designs are common for finishing, while single-flute or three-flute designs are used for specific materials and requirements.

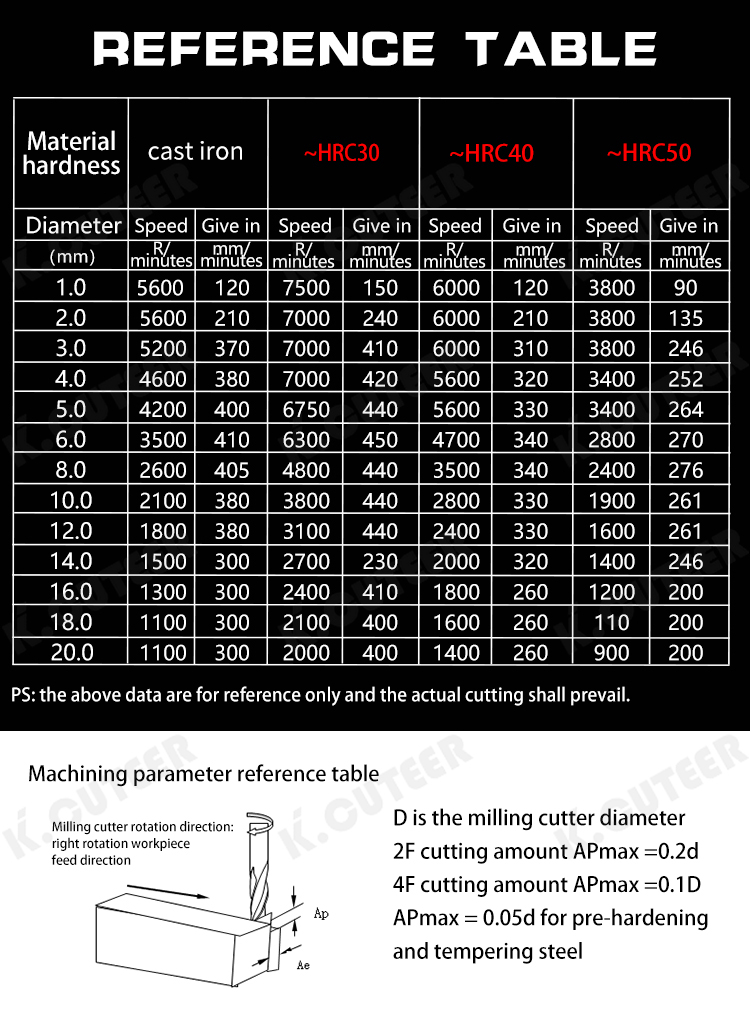

Demanding Application Requirements: They must be used with high-performance CNC machines, high-precision tool holders (e.g., hydraulic or thermal shrink fit holders), and a stable machining environment (vibration-free). High-speed spindles (>20,000 RPM) and precise coolant delivery are often essential.