| Availability: | |

|---|---|

| Quantity: | |

The WCMX U-drill inserts are engineered for high-performance drilling. Their main features include:

High-Efficiency Drilling: Primarily designed for rapid drilling and deep-hole machining. Their U-shaped cutting edge helps distribute cutting force effectively, reducing vibration and deflection for more stable drilling.

Material and Coating: They are typically made from super-fine grain cemented carbide (hard metal), providing a strong base. Many are also available with advanced multi-layer gradient coatings (like TiAlN or TiCN), which significantly enhance wear resistance, impact resistance, and heat dissipation.

Internal Cooling Design: Many WCMX inserts are specifically designed for use with internal coolant systems (center through-tool coolant). High-pressure coolant is directed precisely to the cutting edge through the drill body and insert, which aids in chip evacuation, reduces heat, and prolongs tool life.

Wide Application Range: These inserts are suitable for drilling a variety of materials, including steel, stainless steel, cast iron, aluminum alloys, and even difficult-to-machine materials like high-temperature alloys.

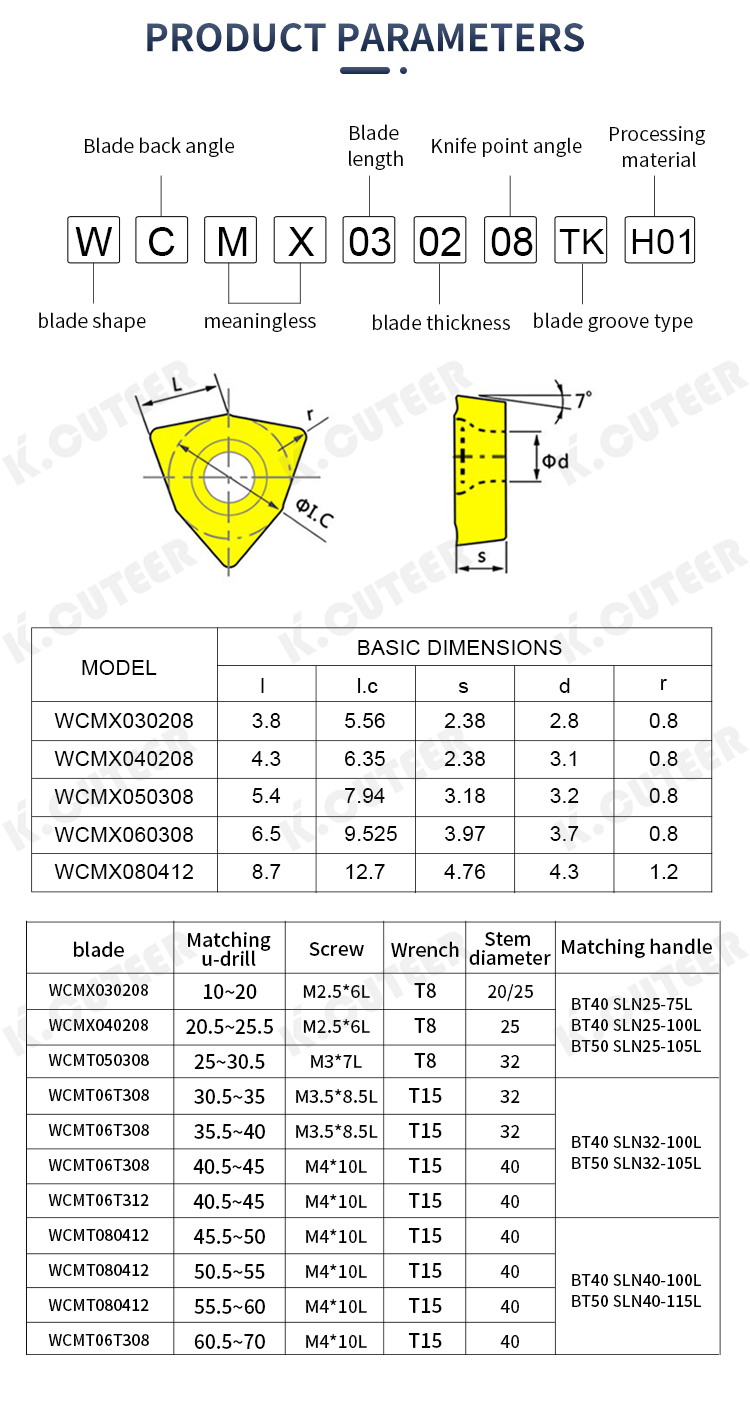

The full model number of a WCMX insert (e.g., WCMX030208) contains specific dimensional and geometric information:

WCMX: The insert series.

03: Often corresponds to the inscribed circle size of the insert (a key mounting dimension).

02: Usually indicates the insert's thickness.

08: Often refers to the corner radius or cutting edge length.

WCMX U-drill inserts are widely used in industries requiring high-precision and efficient hole-making, such as:

Automotive manufacturing (engine blocks, wheel hubs)

Aerospace component machining

General metalworking and mold making