| Availability: | |

|---|---|

| Quantity: | |

1. Face Mills

Product Description: Designed for high-efficiency machining of large, flat surfaces. These cutters feature a large diameter and utilize indexable inserts with multiple cutting edges, enabling high metal removal rates and excellent surface finish.

Key Features: Multiple insert geometries and grades, robust body design, options for fine-pitch and coarse-pitch.

2. End Mills (Solid Carbide & Indexable)

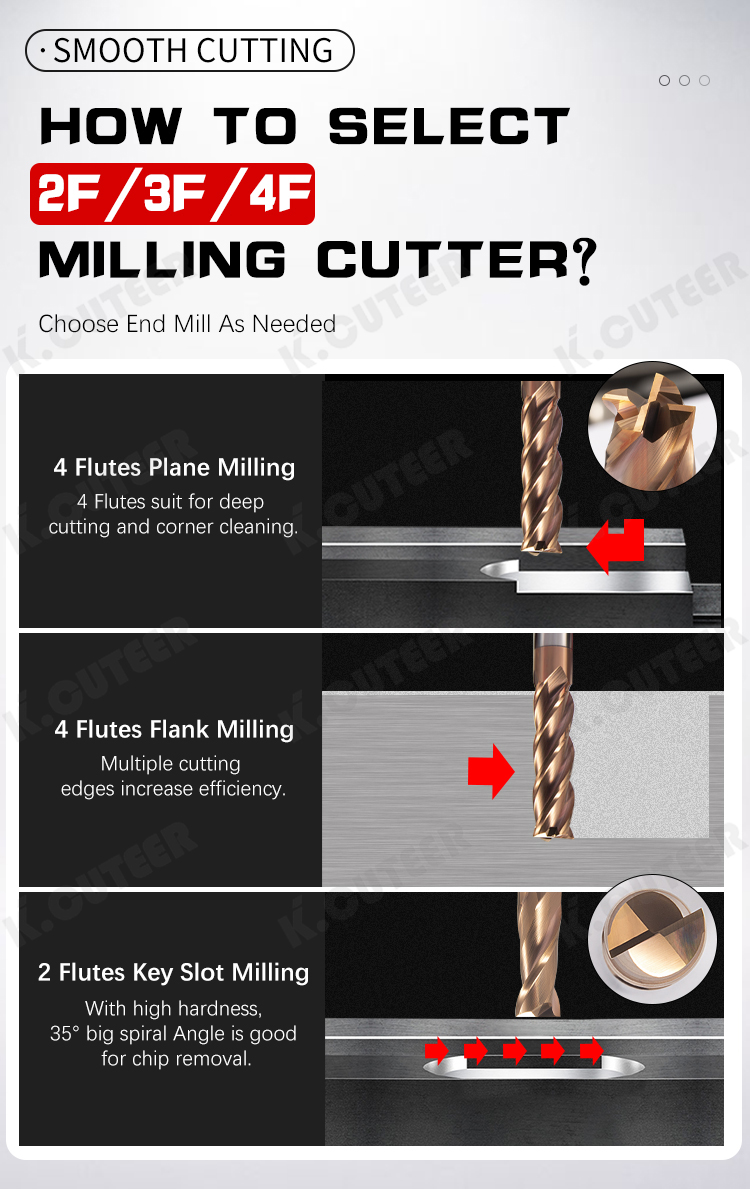

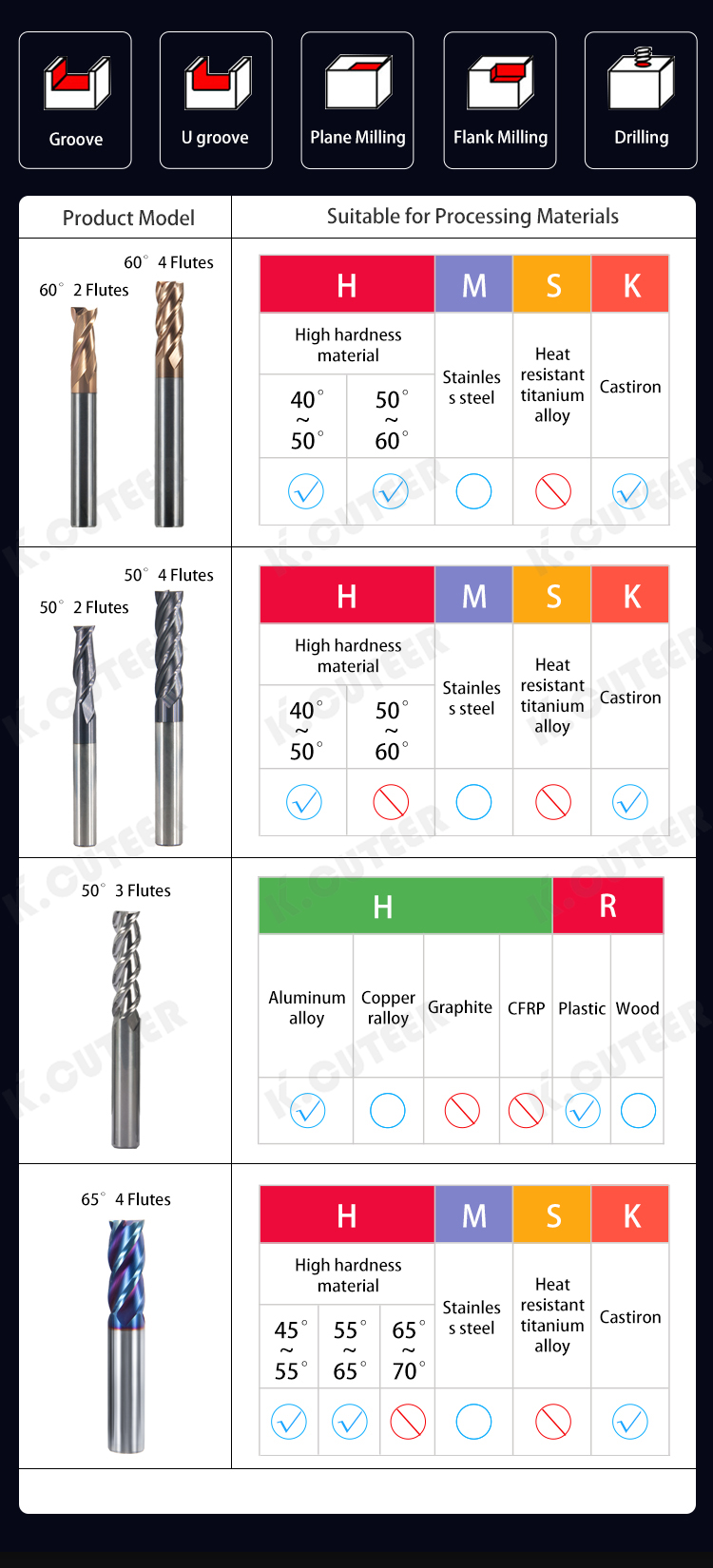

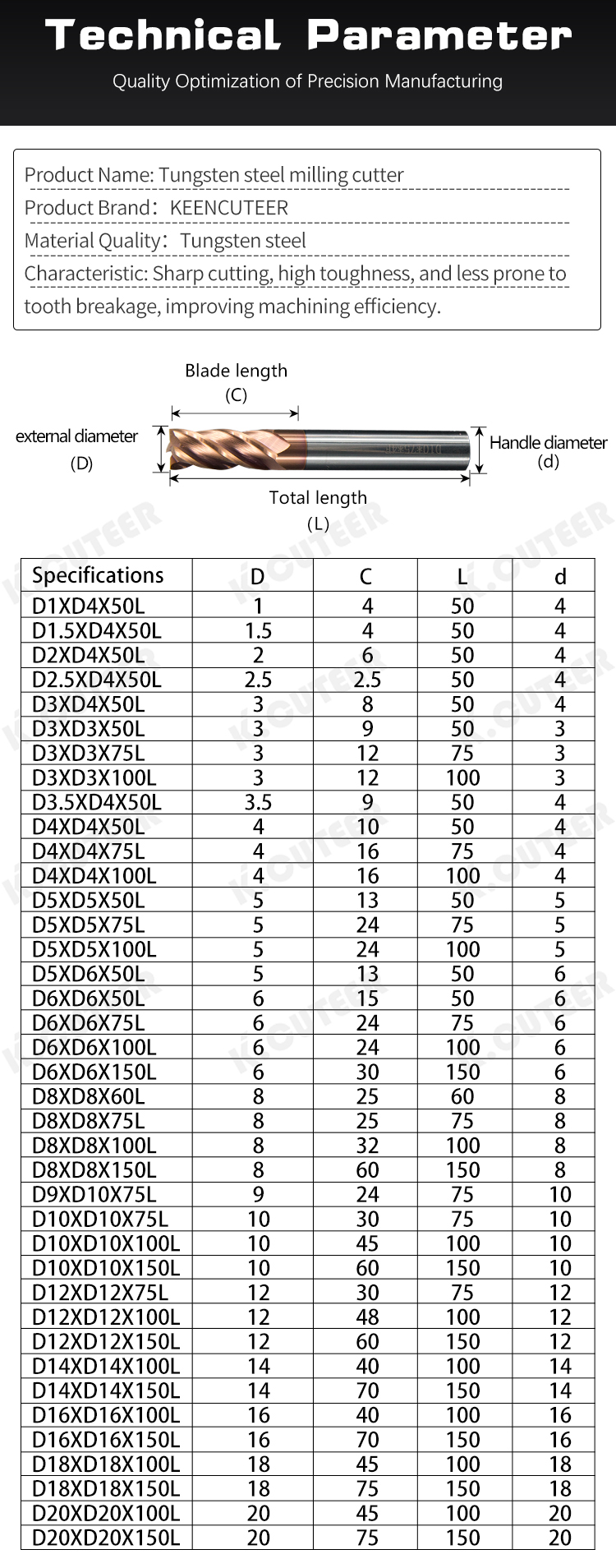

Product Description: The versatile workhorses for machining slots, profiles, pockets, and complex contours. Our range includes square end, ball nose, and corner radius end mills in both solid carbide and indexable designs.

Key Features:

Solid Carbide: Maximum rigidity, high precision, excellent for finishing and high-speed machining.

Indexable: Cost-effective for larger diameters, easy edge replacement, reduced downtime.

3. Shoulder Mills / Square Shoulder Mills

Product Description: Specifically designed for machining accurate 90° shoulders and faces in a single operation. They provide high axial and radial precision, ensuring perfect squareness.

Key Features: True 90° shoulder, high metal removal rates, excellent stability.

4. Slotting Mills / Slotters

Product Description: Used for cutting precise slots and for parting-off operations. They are available in widths for creating standard or custom-sized slots.

Key Features: Precision ground width, high stability to prevent deflection, specialized inserts for efficient chip evacuation.

5. Ball Nose Mills

Product Description: Essential for 3D contouring, die & mold machining, and producing complex curved surfaces. The ball-shaped end allows for smooth material flow and precise geometry replication.

Key Features: Ideal for semi-finishing and finishing, available in long-reach and miniature designs.

6. Roughing End Mills (Hog Mills)

Product Description: Engineered for aggressive stock removal. Their serrated cutting edges break chips into small, manageable pieces, allowing for deeper cuts and higher feed rates.

Key Features: High material removal rate, reduced vibration, extended tool life.

7. Chamfer Mills

Product Description: Used for creating beveled edges, deburring, and chamfering. They are available in various angles, most commonly 45° and 90°.

Key Features: Fast and precise chamfering, eliminates secondary deburring operations.

8. T-Slot Cutters & Dovetail Cutters

Product Description: Specialized tools for machining T-slots for machine vises and dovetail slides for guiding mechanisms.

Key Features: Precise profile, high-strength design for interrupted cuts.

Our Technological Edge:

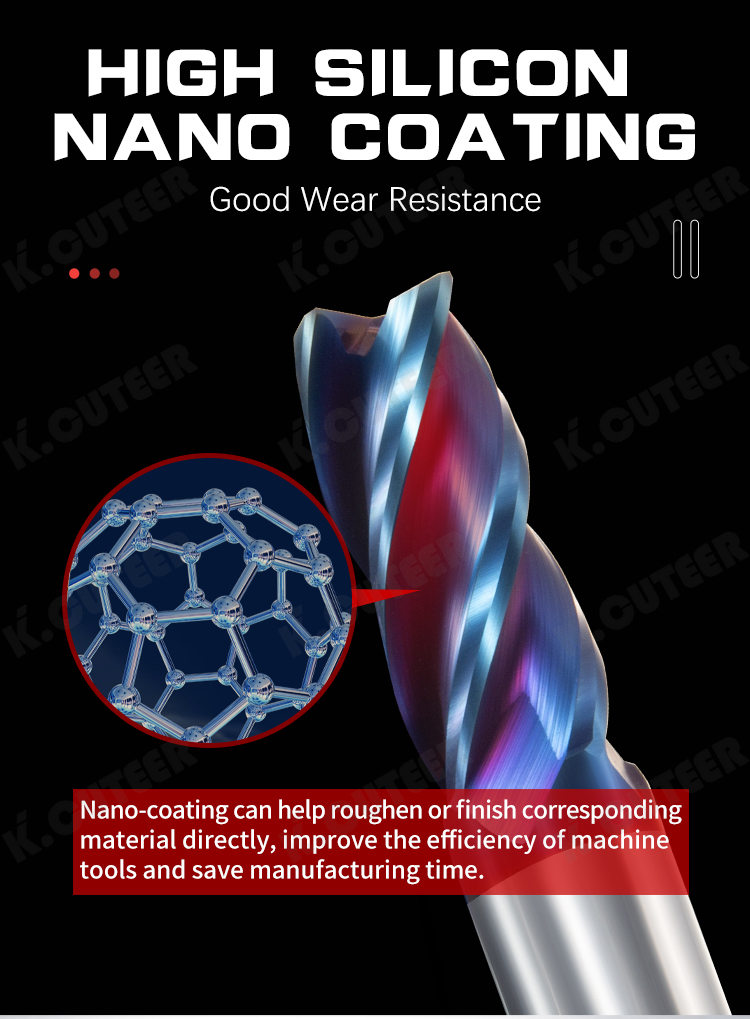

Advanced Substrates & Coatings: We utilize premium micro-grain carbide substrates and state-of-the-art coatings (e.g., TiAlN, AlTiN, DLC) to enhance wear resistance, thermal stability, and tool life.

Optimized Geometries: Each cutter features a geometry optimized for specific materials (e.g., steel, stainless steel, aluminum, heat-resistant alloys) and applications (e.g., roughing, finishing), ensuring optimal chip control and cutting forces.