| Availability: | |

|---|---|

| Quantity: | |

Specification:

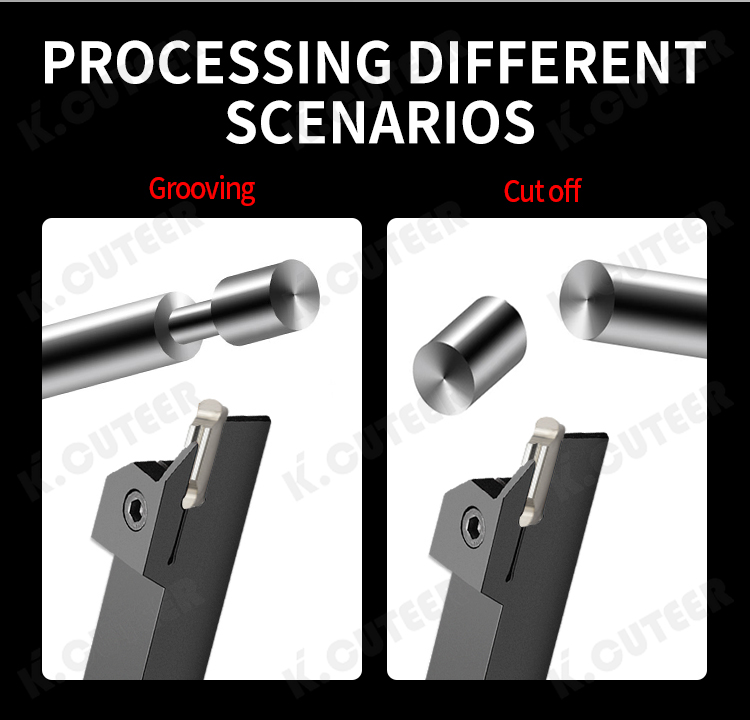

Name: Grooving and cutting CNC blade

Brand: KEENCUTEER

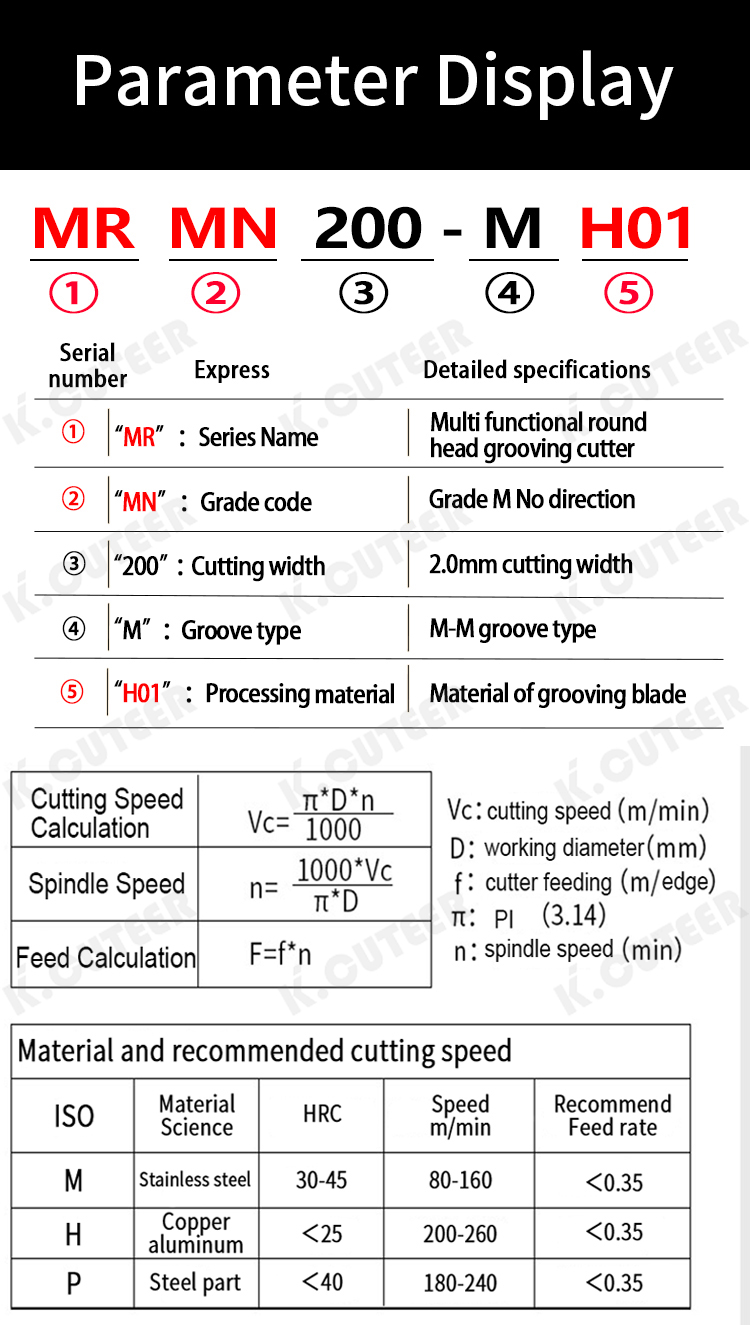

ItemNo.: MRMN/MRGN

Suitable for: MGEHR/L

H01: For aluminum and copper parts processing.

-G:finishing groove type.with strong chip removal capability.

-M:Universal groove type, both fine and coarse can be processed.

Features:

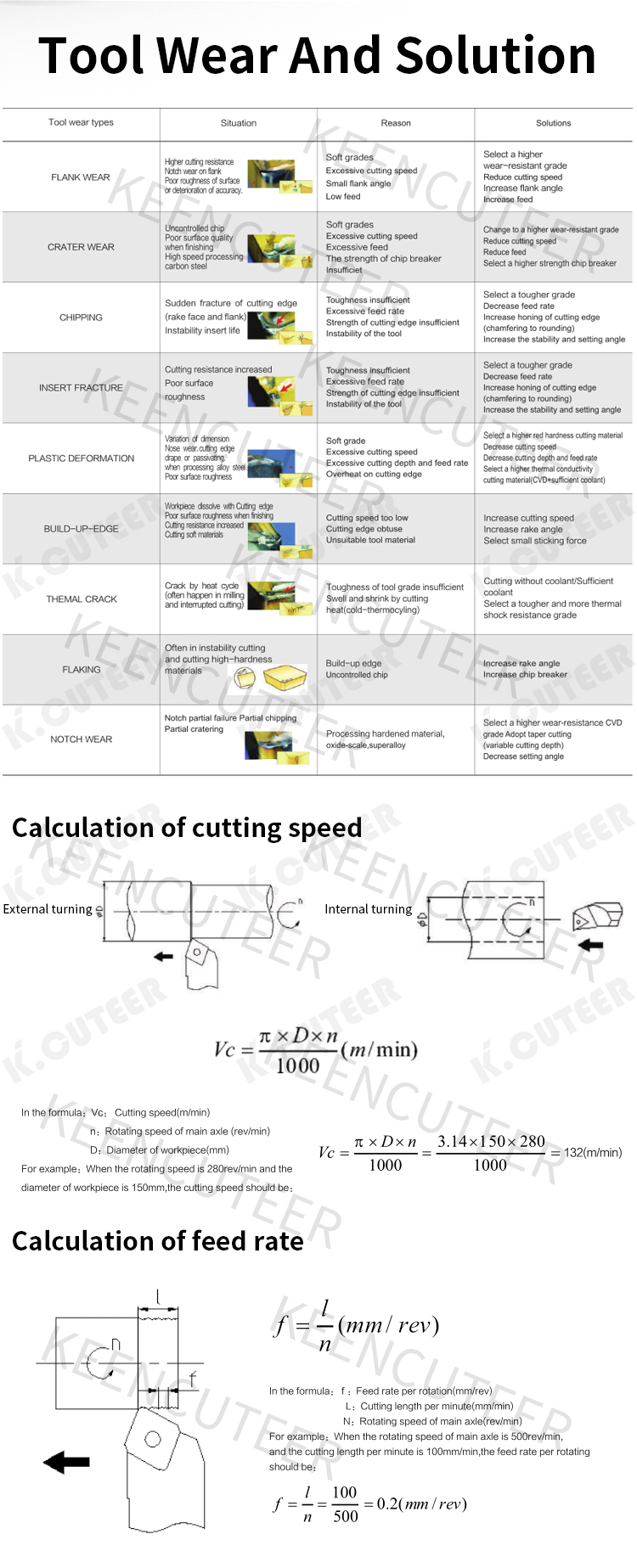

1. Reduces friction between chips and workpieces, resulting in better surface roughness.

2. Good chip removal, less likely to stick to the tool.

3. More wear-resistant, reduces tool replacement, and improves production efficiency.

Insert Geometry (MGGN): The MGGN is a standardized code for a square-shaped, negative rake angle insert designed for grooving and cut-off operations. This geometry is versatile and can also be used for light side-turning (copying).

Grade & Coating (H01): The H01 grade typically refers to a specialized coating and substrate combination. For machining aluminum, it often involves a Titanium Diboride (TiB₂) or similar coating.

This coating is crucial because it has a very low chemical affinity with aluminum, which significantly revents the built-up edge (BUE). BUE is a common problem when machining soft, sticky materials like aluminum, as it degrades surface finish and tool life.

Key Advantages:

Anti-Adhesion: The primary benefit is its non-stick property, ensuring a clean cut and excellent surface finish on aluminum parts.

Sharp Cutting Edge: These inserts are typically ground with a very sharp edge to enable clean shearing of the soft material, reducing cutting forces.

High-Speed Suitability: The combination of geometry and coating makes this insert well-suited for high-speed machining of aluminum.

This type of insert is ideal for manufacturing components in industries like automotive, aerospace, and general machinery where efficient aluminum machining is critical.