| Availability: | |

|---|---|

| Quantity: | |

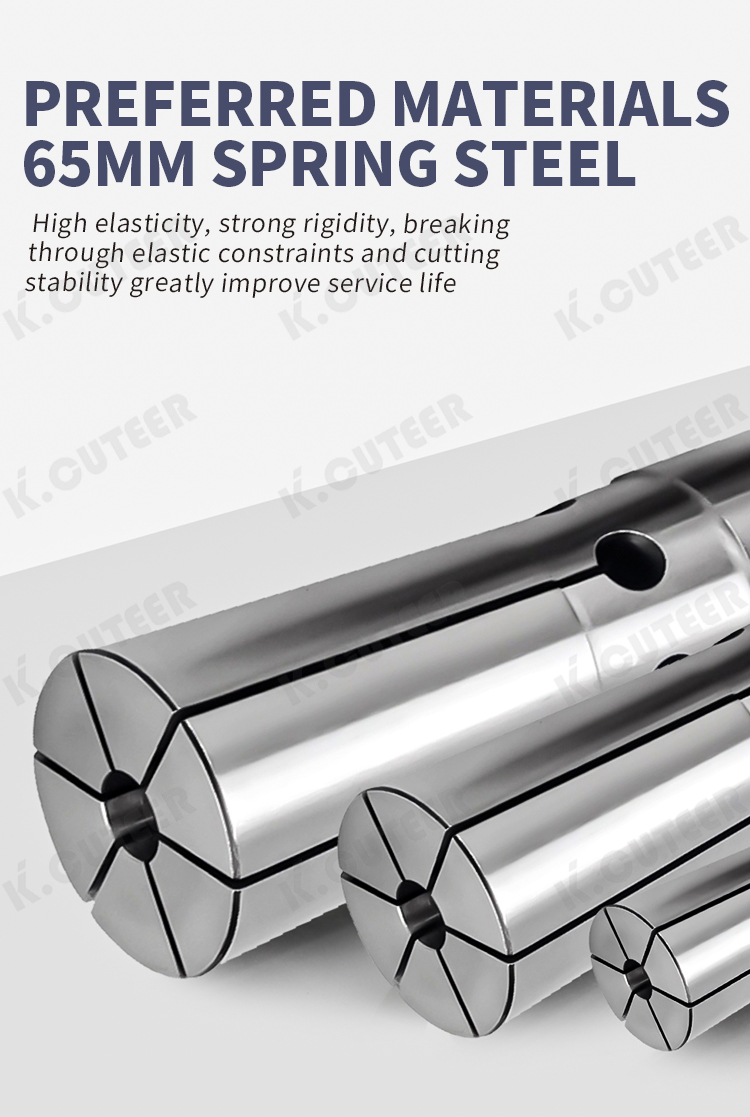

Key Features & Benefits

Dual Contact Interface: Unlike standard BT or CAT holders that only contact at the taper, the DC collet chuck features a special flange design. This allows it to make rigid, metal-to-metal contact at both the 7/24 taper and the spindle face, similar to the principle of HSK tooling.

High Rigidity and Stability: This double-contact design drastically increases the overall rigidity of the toolholder-spindle connection. It minimizes tool vibration and deflection during cutting, which is crucial for heavy machining and high-speed applications.

Improved Accuracy and Repeatability: The enhanced connection provides superior radial and axial runout accuracy, ensuring precise tool positioning and outstanding part quality. It also offers excellent repeatability during tool changes.

Extended Tool Life: By reducing vibration and chatter, the DC collet chuck contributes to longer tool life for both the cutting tool and the collet itself.

Increased Productivity: The stability allows for higher metal removal rates (MRR), deeper cuts, and sometimes higher spindle speed utilization compared to standard single-contact holders.

Common Applications

The DC collet chuck is ideally suited for applications demanding high precision, finish, and stability:

High-Speed Machining (HSM)

Heavy-duty milling and roughing

Finishing operations requiring excellent surface quality

Processes where minimal runout is critical (e.g., micro-machining)

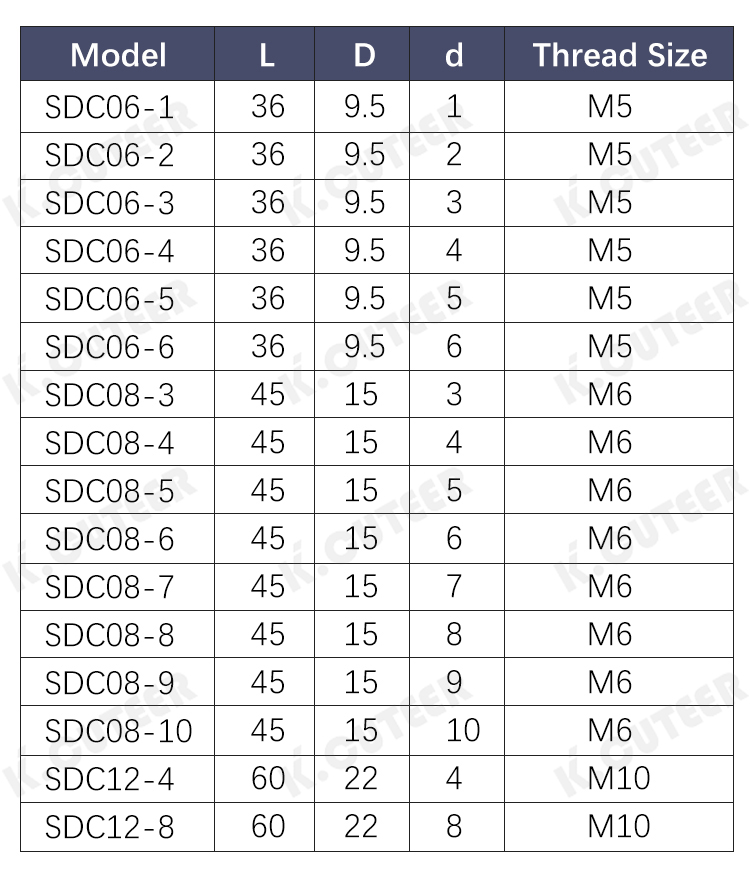

Compatibility

The DC collet chuck system is available in common taper sizes such as DC 40, DC 50, etc. It is compatible with standard collet types (like ER collets) and is designed for use on machining centers equipped with corresponding DC-type spindles.