| Availability: | |

|---|---|

| Quantity: | |

Specification:

YZ15TF:Used to process stainless steel and reduce tool breakage.

KT1505:Used for processing steel and Stainless iron.

YZ5010A:for machining any superhard material, suitable for 40-60 degrees.

Package includes:

NO insert : there is only one tool bar and wrench in the package.

NO Cutter bar : There are only 10 blades in the kit.

If you choose both blade and holder, you will receive 10pc blades, 1pc holder and wrench.

Key Features & Innovations:

1.Pentagonal Insert Design: Equipped with a 10-cutting-edge, double-sided pentagonal insert. This design significantly reduces cost per cutting edge while providing excellent stability through its double-sided clamping mechanism.

2.Low Cutting Resistance & Anti-Chipping: Features a circular edge geometry that achieves low cutting resistance and an axial rake angle of up to 10°. It incorporates a dual-edge design that helps control vibration and minimizes chipping, ensuring a stable and smooth machining process.

3.Enhanced Chip Evacuation: The cutter is designed to facilitate smooth and efficient chip removal.

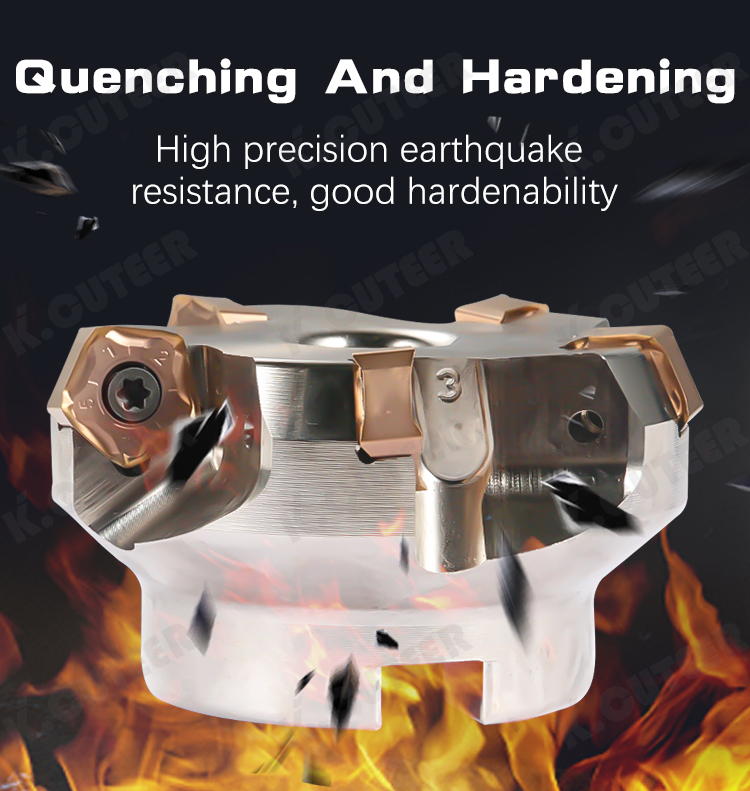

4.Long Tool Life: Utilizes Kyocera's proprietary MEGA Coating technology, which contributes to an extended tool life.

Primary Application:

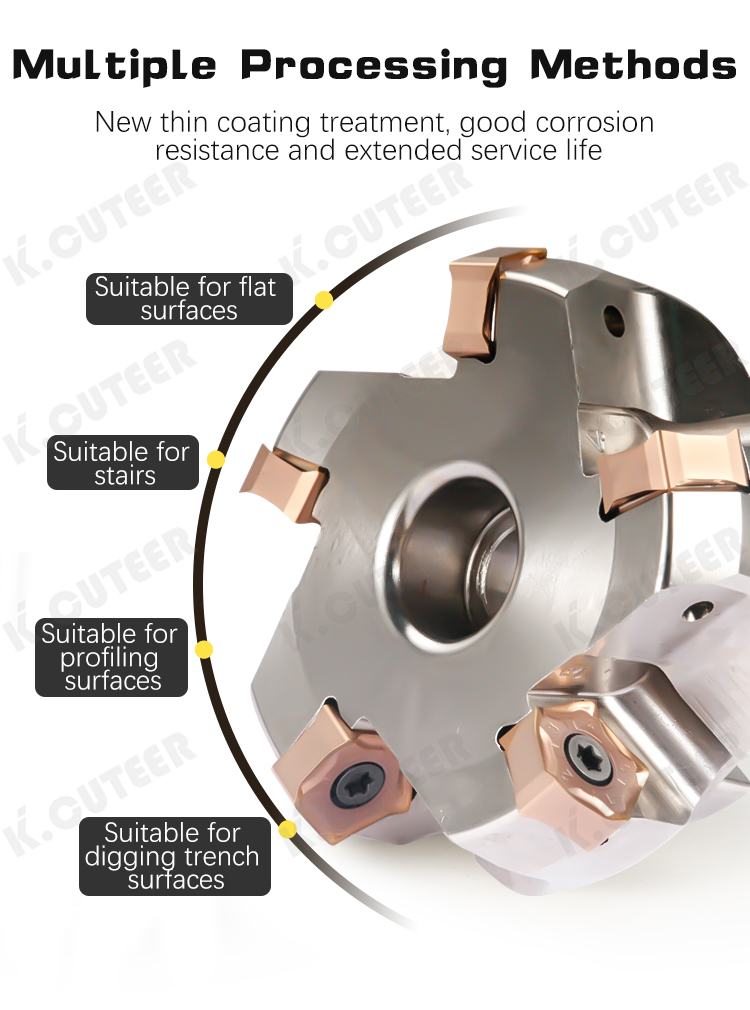

The MFPN cutter is ideally suited for plane milling applications where high efficiency is a primary requirement. Compared to conventional face mills, it can substantially boost production efficiency in high-feed machining.