| Availability: | |

|---|---|

| Quantity: | |

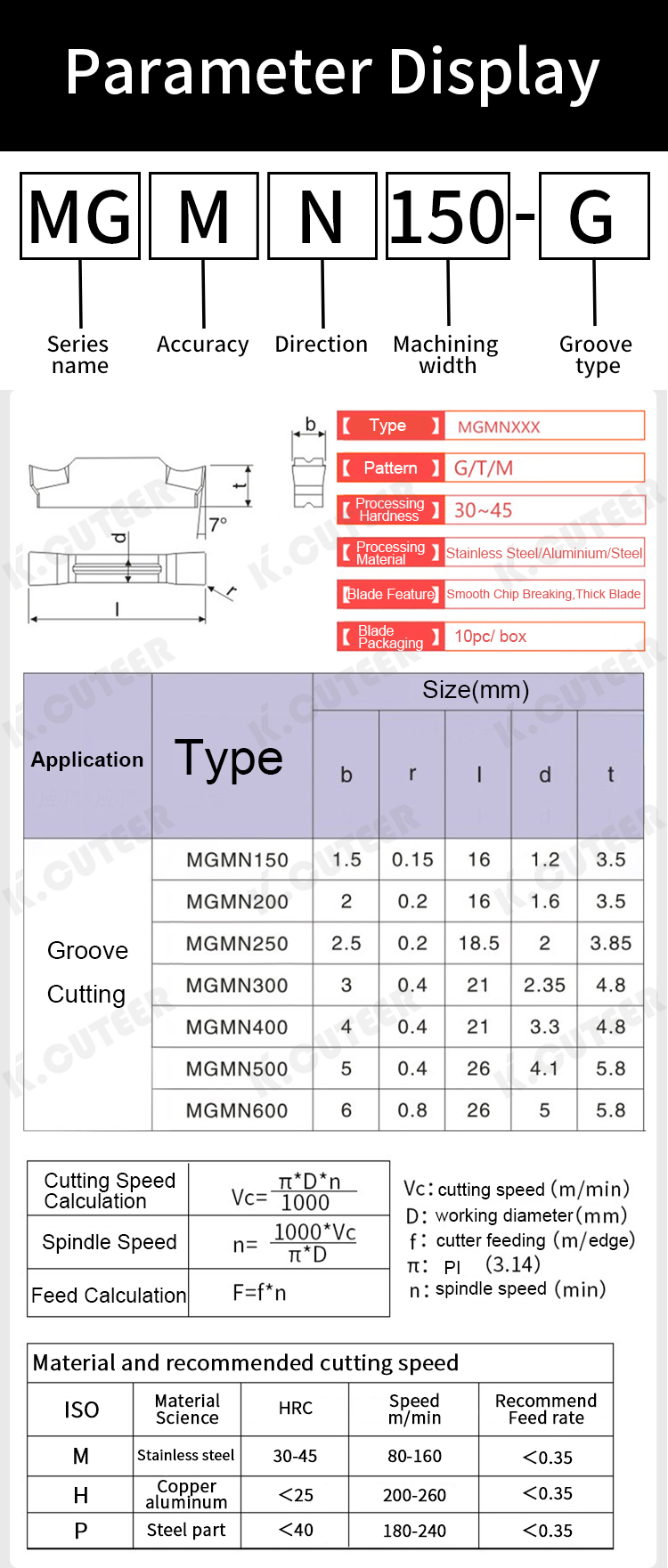

The MGMN code denotes a square-shaped, negative rake insert.

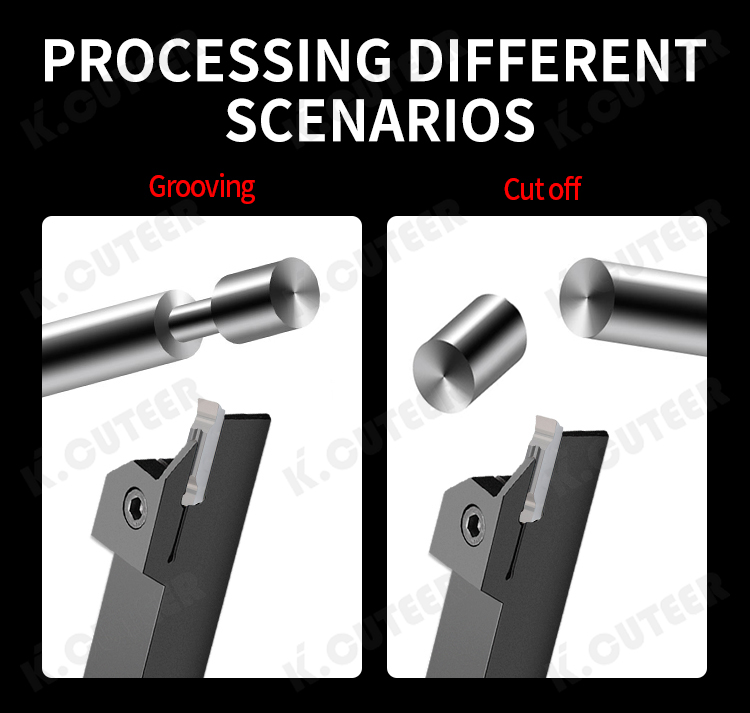

It is a versatile insert used for:

Grooving

Cut-off (parting)

Light side-turning (copying)

KT60 is a silicon nitride (Si₃N₄) based ceramic composite, often reinforced with silicon carbide whiskers. This structure gives it exceptional toughness and thermal shock resistance compared to other ceramics.

It is engineered to maintain its hardness at temperatures where carbide tools would fail.

Extreme Hot Hardness: Can run at surface speeds 10 to 20 times higher than carbide, maintaining its cutting edge integrity at very high temperatures generated by high-speed machining.

Superior Wear Resistance: Highly resistant to abrasive wear, leading to extremely long tool life in suitable applications.

High Productivity: Drastically reduces machining times by enabling very high cutting speeds.

Suitable for Hard Materials: Excellent for machining hardened steels (45 HRC and above) without the need for coolant.

This insert is ideal for:

High-speed grooving and turning of grey cast iron (e.g., in the automotive industry).

Machining hardened steel components.

Finishing superallies (e.g., Inconel), where its hot hardness provides a significant advantage.

Important Note: Ceramic inserts like KT60 are brittle compared to carbide. They require very rigid machine tools, secure workpiece clamping, and often must be used without coolant to avoid thermal shock.

In summary, the MGMN KT60 insert combines a versatile grooving geometry with a high-performance whisker-reinforced ceramic grade, making it a specialized solution for high-productivity, high-speed machining of hard and abrasive materials.