| Availability: | |

|---|---|

| Quantity: | |

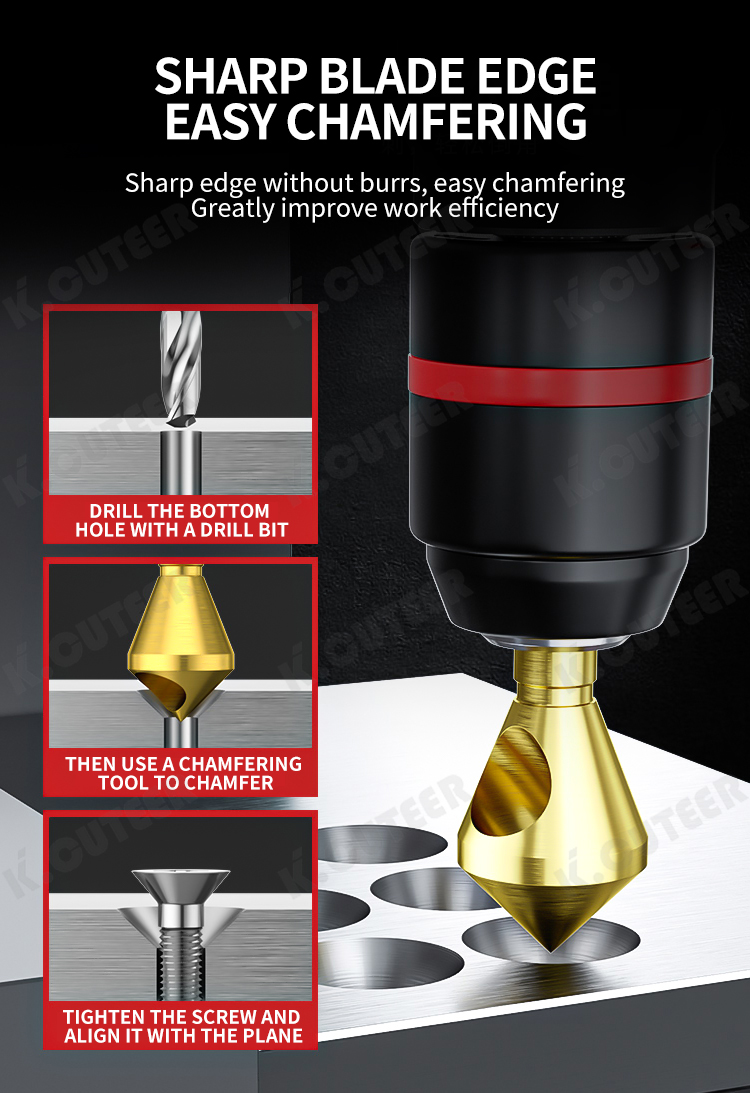

Key Features & Benefits

Standard Angle: The 90-degree angle is the most common standard, making this tool versatile for a wide range of applications. It is perfectly suited for fasteners with 90° countersunk heads, such as flat-head screws, ensuring they sit flush with or below the workpiece surface.

Deburring: Apart from creating chamfers for screws, it is highly effective for deburring—removing the sharp, rough edges (burrs) left on holes after drilling or tapping operations, thereby improving part safety and handling.

Improved Assembly and Aesthetics: It facilitates smoother assembly by providing a lead-in for pins, shafts, or other components. The chamfered edge also gives the product a more finished and professional appearance.

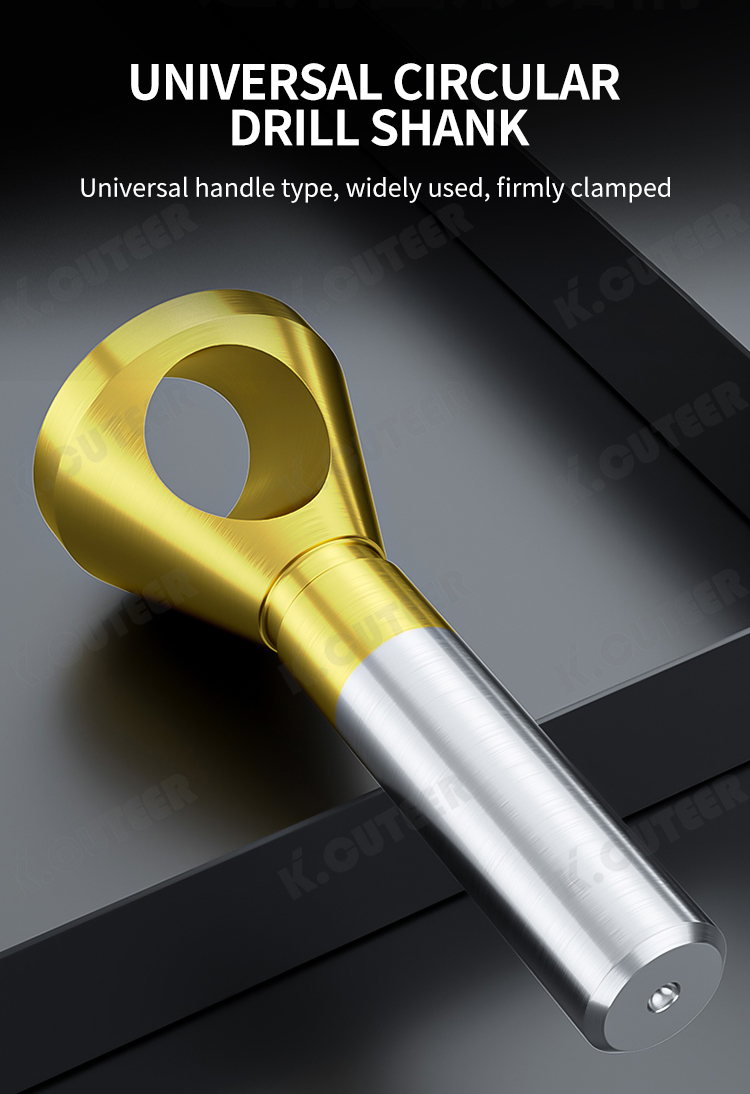

Versatility: Available in various types including fixed-angle countersinks, adjustable countersinks, and inserted-blade countersinks. They can be used in handheld tools like deburring machines or in CNC machining centers.

Multiple Flutes: Typically features multiple cutting edges (e.g., 3, 5, or 6 flutes) for balanced cutting, smoother operation, and enhanced surface finish.

Common Applications

Creating chamfers for flat-head screws.

Deburring holes in sheet metal, plates, and machined parts.

Preparing edges for welding.

Adding finishing touches to components in automotive, aerospace, and general manufacturing.

Materials and Compatibility

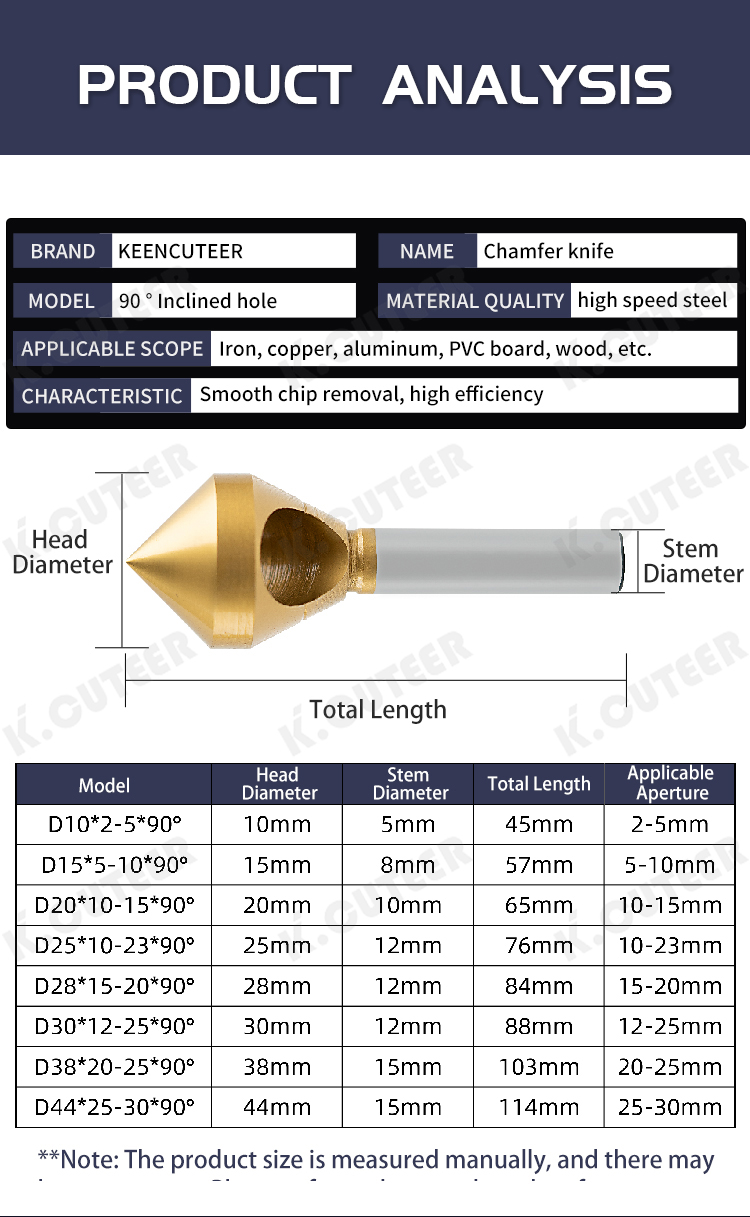

Can be made from High-Speed Steel (HSS), Cobalt Steel (HSS-E), or fitted with Carbide tips for longer life and machining harder materials.

Can be used in a wide range of machines, from simple drill presses to advanced CNC machining centers.