| Availability: | |

|---|---|

| Quantity: | |

PCD End Mill: Technical Overview

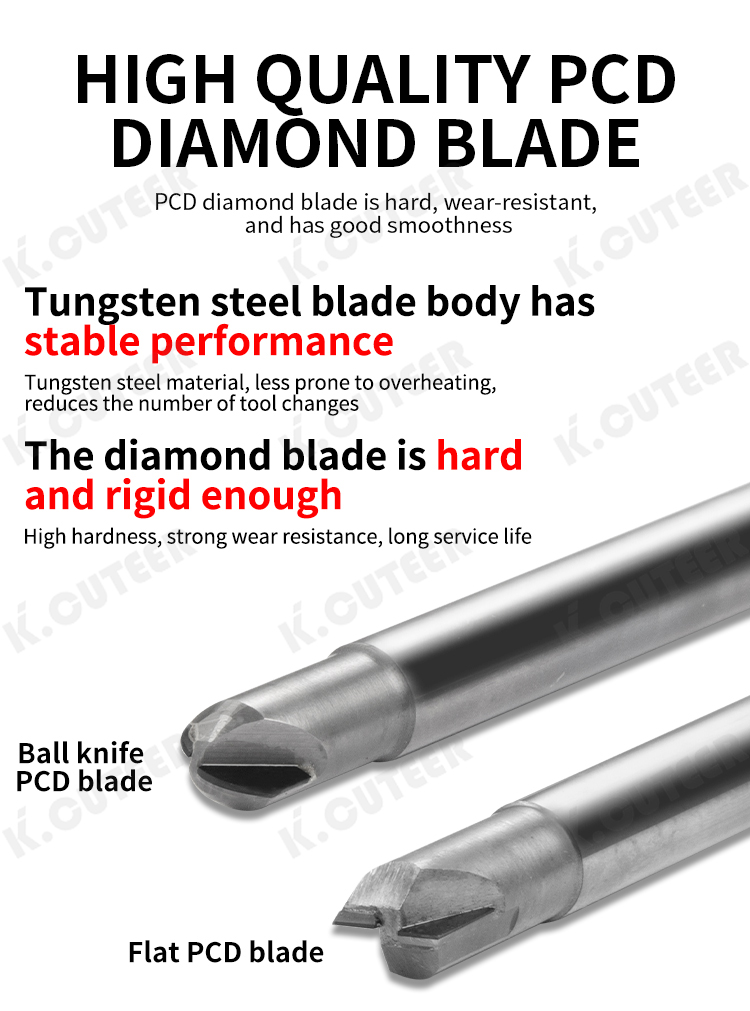

A PCD (Polycrystalline Diamond) End Mill is an advanced cutting tool where the cutting edges consist of a sintered layer of fine diamond grains. This structure gives PCD its unique combination of high hardness and excellent fracture toughness.

Key advantages of using PCD End Mills include:

Exceptional Tool Life: Outlasts carbide tools by up to 100 times in abrasive materials, drastically reducing tool change frequency.

Superior Surface Finish: Allows for high-quality mirror-like finishes, often eliminating the need for secondary operations.

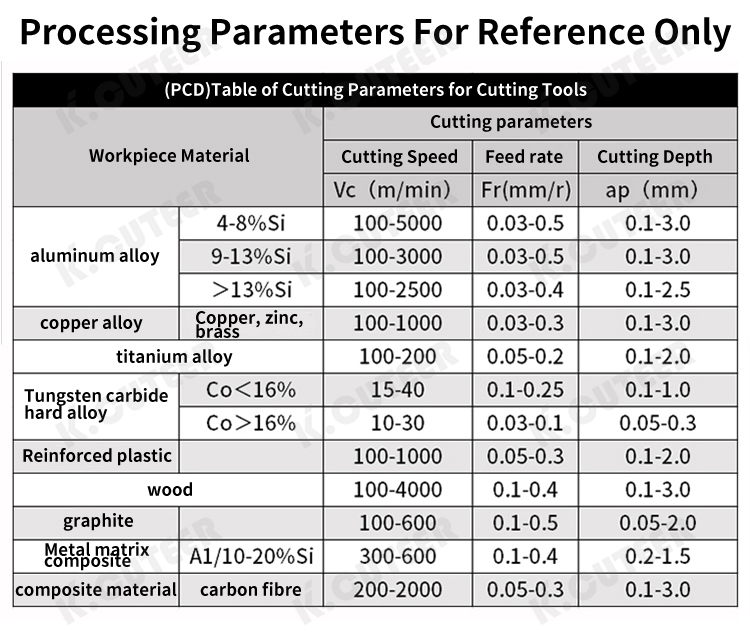

High-Speed Machining: Enables significantly higher cutting speeds than carbide, leading to greater productivity.

Excellent Heat Resistance: Maintains its hardness at high temperatures generated during cutting.

Technical Highlights:

Unmatched Wear Resistance: Ideal for machining highly abrasive materials such as silicon-aluminum alloys, metal matrix composites (MMCs), carbon fiber reinforced plastics (CFRP), and high-silicon aluminum. This results in consistent part quality over very long production runs.

Geometric Stability: The extreme wear resistance ensures that the tool's original geometry and sharpness are maintained, which is critical for holding tight tolerances.

Application-Specific Design: PCD end mills are available in various geometries (e.g., for roughing, finishing, and high-speed machining) to optimize performance for specific materials and operations.

Typical Applications:

Automotive: Machining of engine blocks, cylinder heads (aluminum-silicon alloys).

Aerospace: Machining of composite materials and lightweight aluminum structures.

Electronics: Precise machining of casings and heat sinks.

General Engineering: High-volume production of non-ferrous components.