| Availability: | |

|---|---|

| Quantity: | |

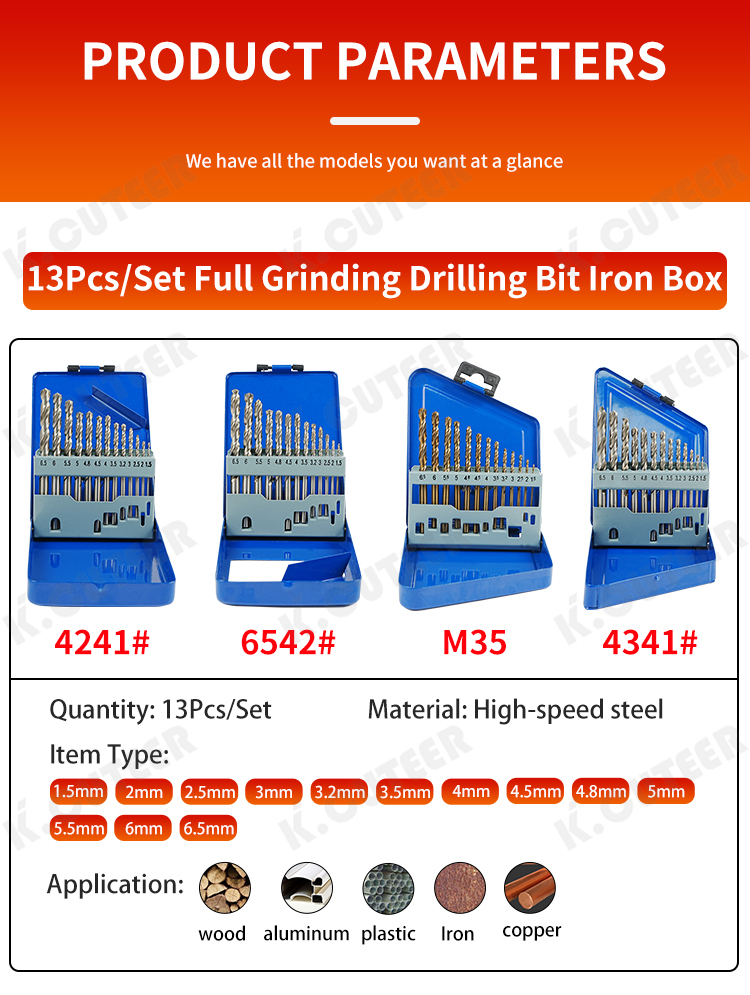

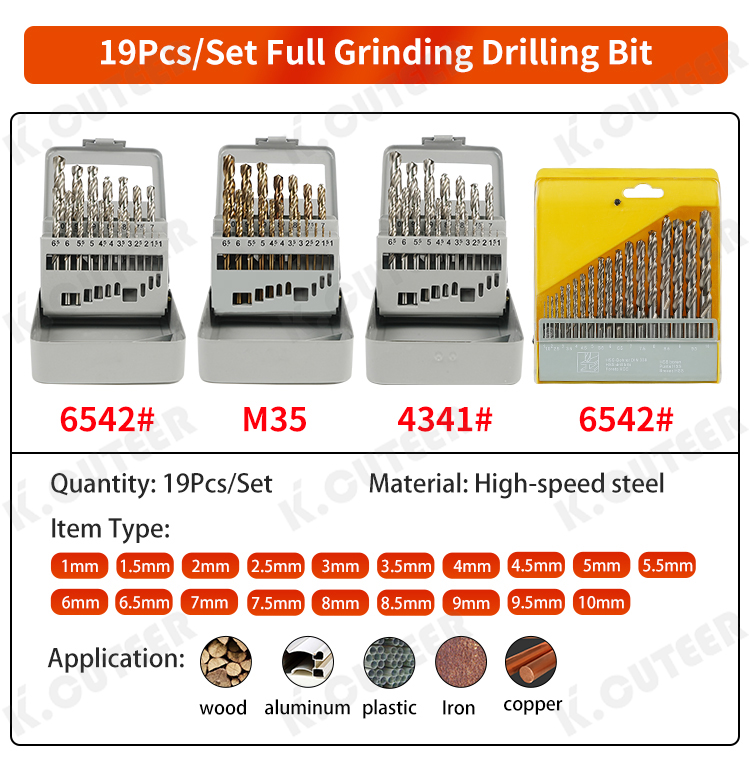

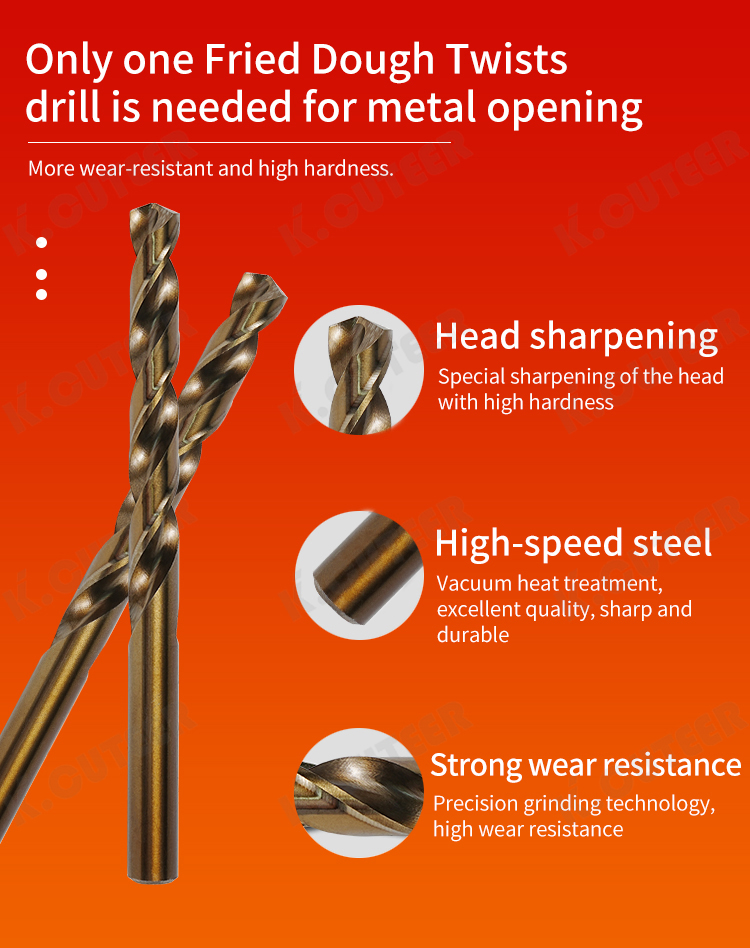

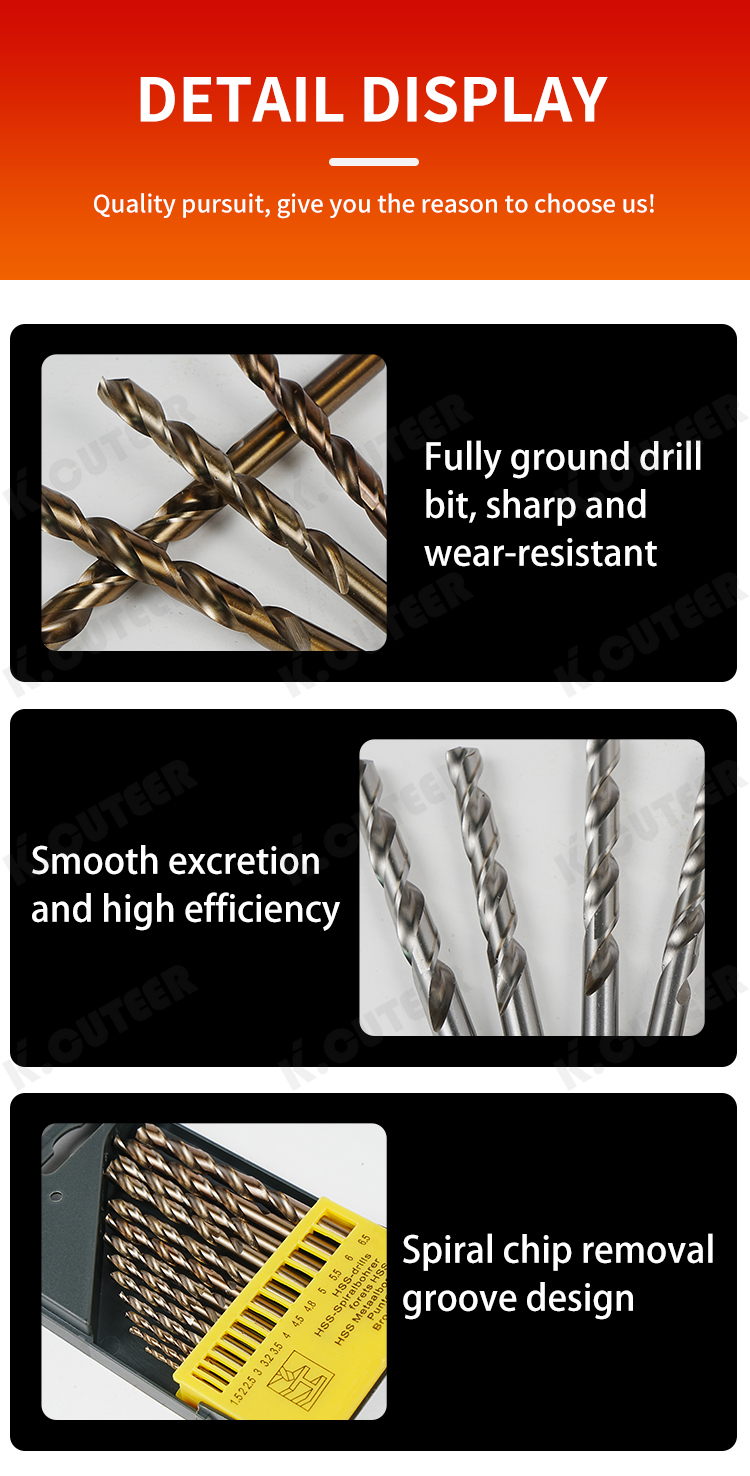

A High-Speed Steel (HSS) twist drill is the most common and versatile metal-cutting tool, named for its helical flutes that resemble a "twist."

Key Features:

Material: Made from High-Speed Steel. HSS is a high-carbon steel alloyed with elements such as tungsten, molybdenum, chromium, and vanadium. After specific heat treatment, it retains high hardness and wear resistance even at elevated temperatures (around 500-600°C), a property known as "red-hardness."

Geometry: Its typical structure consists of helical flutes, cutting edges (lips), a chisel edge (web), and lands. The primary functions of the helical flutes are to remove chips and channel cutting fluid to the cutting area.

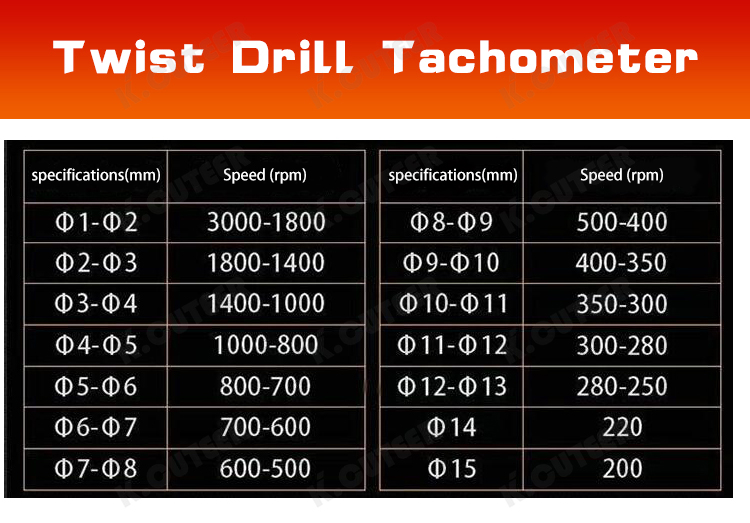

Performance: Compared to carbon steel drills, HSS drills offer higher hardness, better wear resistance, and a longer tool life, enabling higher-speed machining operations.

Coatings: Many HSS drills are coated with surface treatments (such as Titanium Nitride - TiN, Titanium Carbo-Nitride - TiCN, etc.) to further reduce friction, increase surface hardness, enhance heat resistance, and extend service life.

Applications:

Widely used in industries including general machinery manufacturing, automotive, aerospace, and mold & die making, for drilling holes in a wide range of materials such as steel, cast iron, non-ferrous metals (e.g., copper, aluminum), and plastics.

Advantages:

High versatility for machining various materials.

Good toughness, capable of withstanding some impact.

Excellent cost-effectiveness, offering a great balance between performance and price.

Regrindable, allowing multiple sharpening sessions to restore cutting performance.