| Availability: | |

|---|---|

| Quantity: | |

Key Characteristics and Features:

1.Comprehensive Kit:

The set usually includes multiple holders of different types and sizes, offering a ready-to-use solution for a wide range of machining applications without the need to purchase individual holders separately.

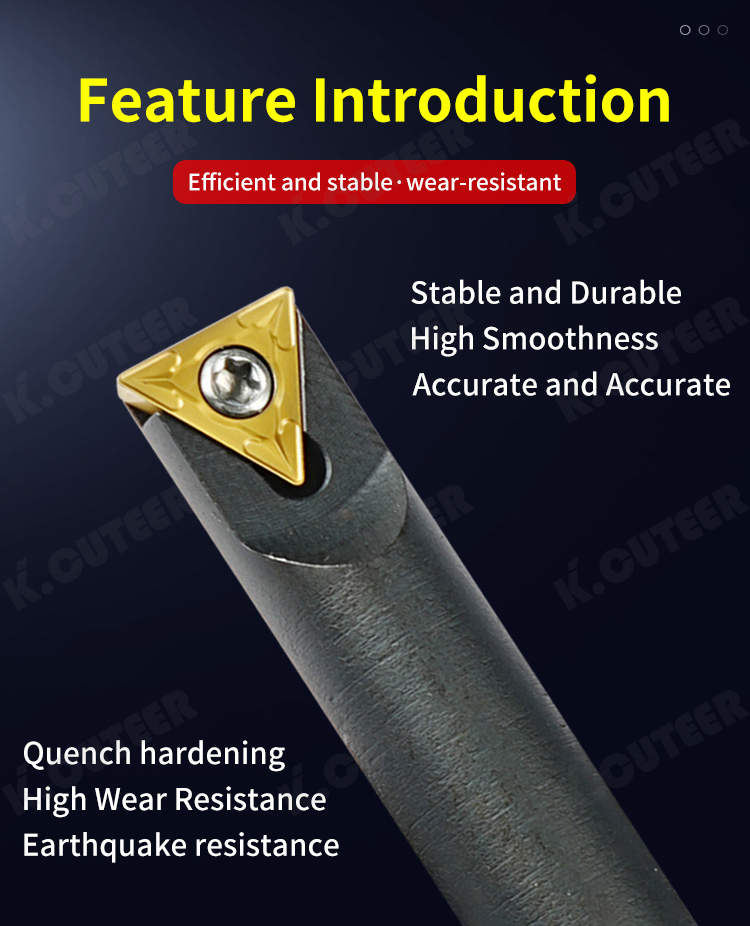

2.Black Surface Finish:

The black color typically comes from a specialized surface treatment, most commonly Nitriding (e.g., QPQ - Quench-Polish-Quench) or a Black Oxide coating.

Primary Benefits of the Finish:

(1)Enhanced Wear Resistance: The hardened surface layer significantly increases the service life of the holders.

(2)Improved Corrosion Resistance: Protects against rust and coolant, ensuring longevity.

(3)Reduced Friction & Galling: The smooth, hard surface minimizes friction with the tool and the machine spindle, facilitating smoother tool changes and better grip.

(4)Aesthetic Appeal: Provides a uniform, professional, and clean appearance.

3.High Precision and Rigidity:

(1)These holders are precision-manufactured to ensure high runout accuracy (e.g., within 0.0005" or less), which is critical for achieving superior machining finish, tool life, and part accuracy.

(2)Robust construction provides maximum rigidity, minimizing vibration during high-speed or heavy-duty cutting.

4.Common Types in a Set:

A typical set may include various holder styles to cover fundamental needs:

(1)ER Collet Chucks: The most versatile type, for holding a wide range of round shank tools.

(2)End Mill Holders: For rigidly holding end mills with set screws.

(3)Tap Holders: For tapping, often with tension/compression float capability.

(4)Shell Mill Holders / Face Mill Arbors: For holding large face milling cutters.

Applications and Advantages:

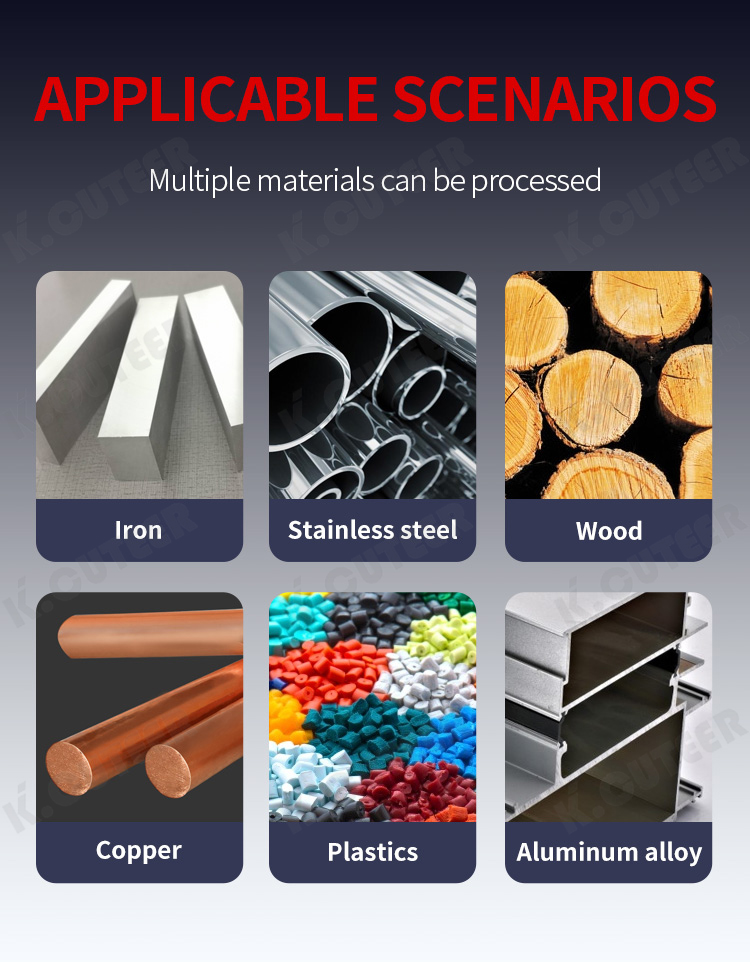

Versatility: Provides a foundational toolkit for CNC machining centers, suitable for operations like milling, drilling, and tapping across various materials.

Convenience: Saves time and effort in tooling setup and procurement.

Performance: The combined benefits of the black finish and precision engineering lead to improved machining performance, reliability, and reduced downtime.

Ideal For: Both workshop startups and seasoned machinists looking for a reliable, all-in-one tool holding solution.

In summary, a black-finish tool holder set represents a premium, high-performance, and practical investment for modern machining. It delivers the essential benefits of precision, durability, and corrosion resistance in a convenient, ready-to-use package.、