| Availability: | |

|---|---|

| Quantity: | |

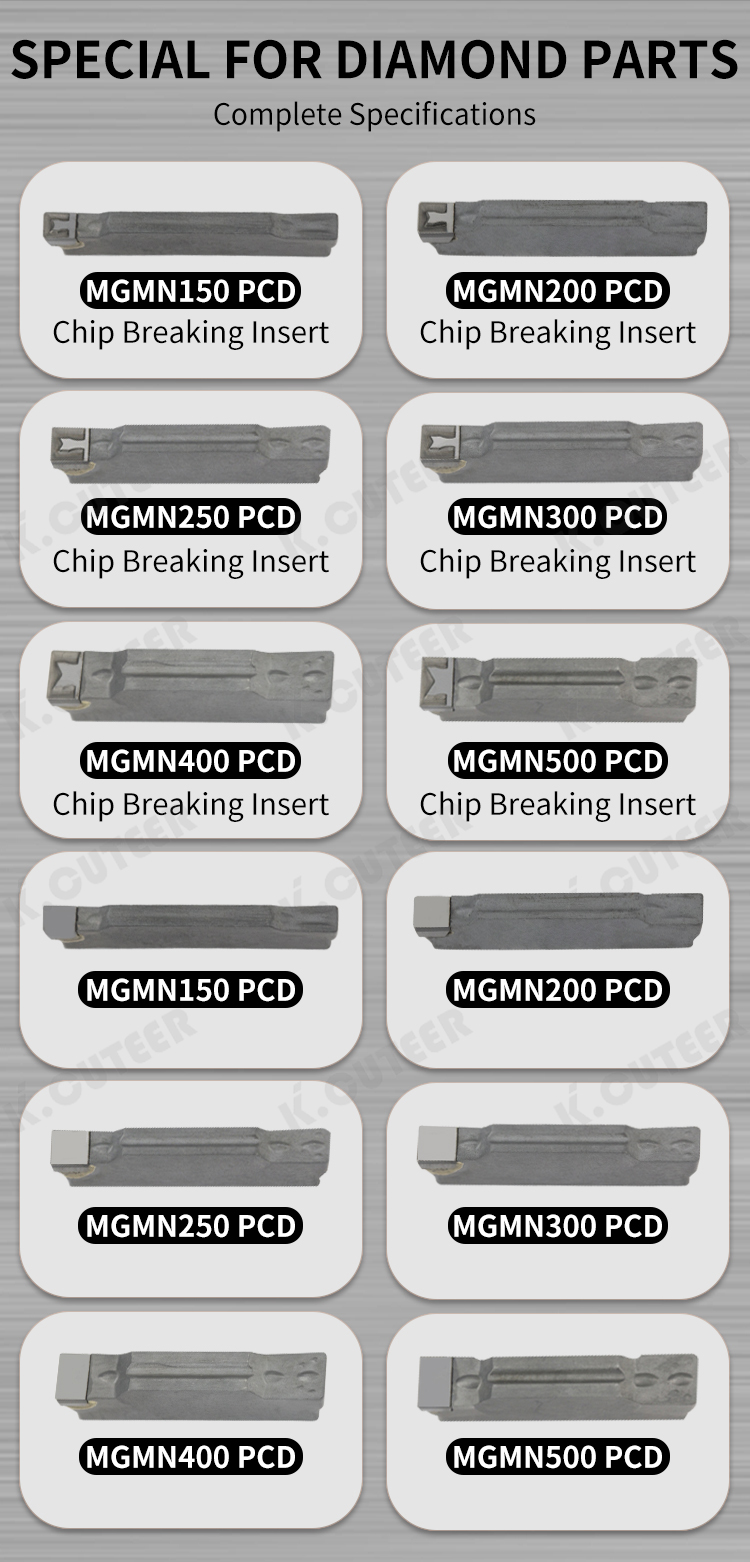

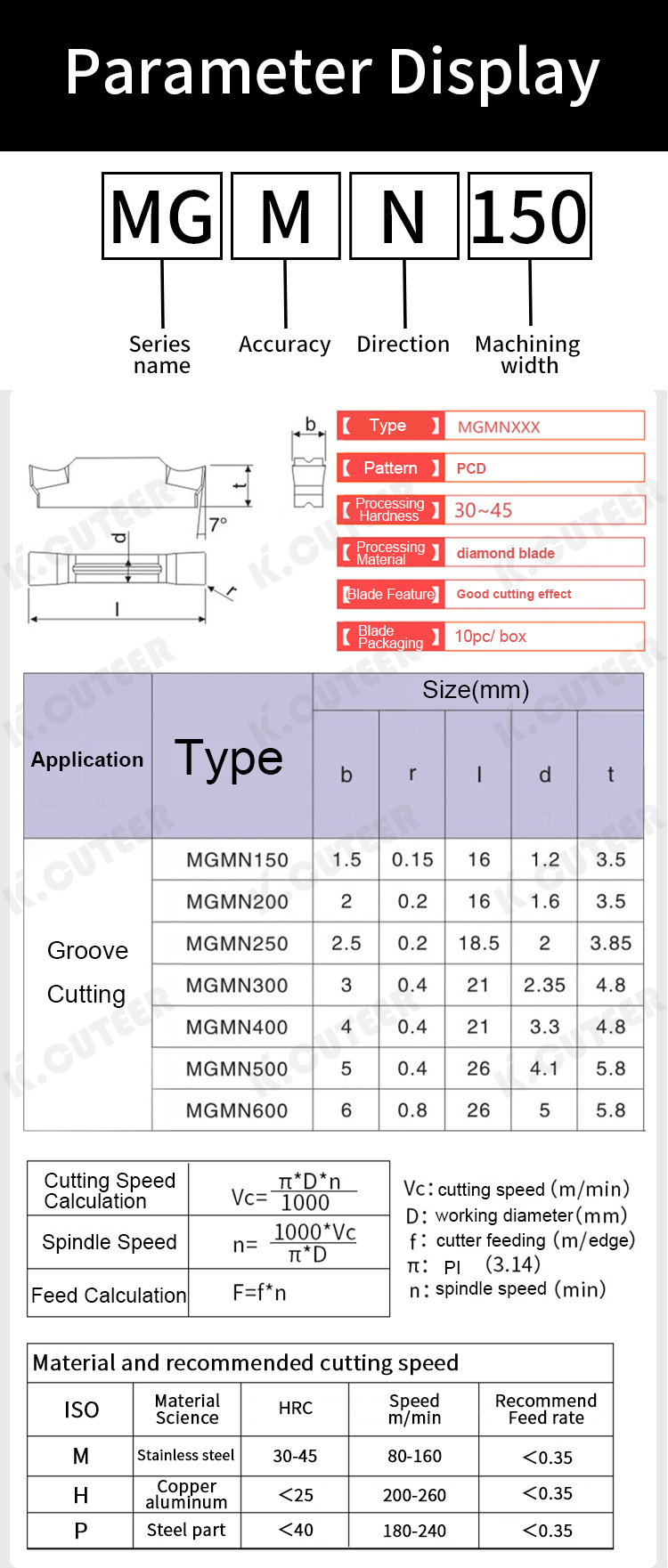

Cutting Material: Features a PCD tip brazed onto a tungsten carbide substrate. PCD consists of synthetic diamond particles sintered together under high pressure and temperature, offering extreme hardness and wear resistance.

Geometry: The MGMN ISO designation indicates a negative-style, square-shaped insert with a very high cutting edge count (typically 8 edges). This geometry provides excellent strength and economy.

Cutting Edge: Can be supplied with a sharp edge for free-cutting or a honed edge (T-land/K-land) for increased strength and chip resistance.

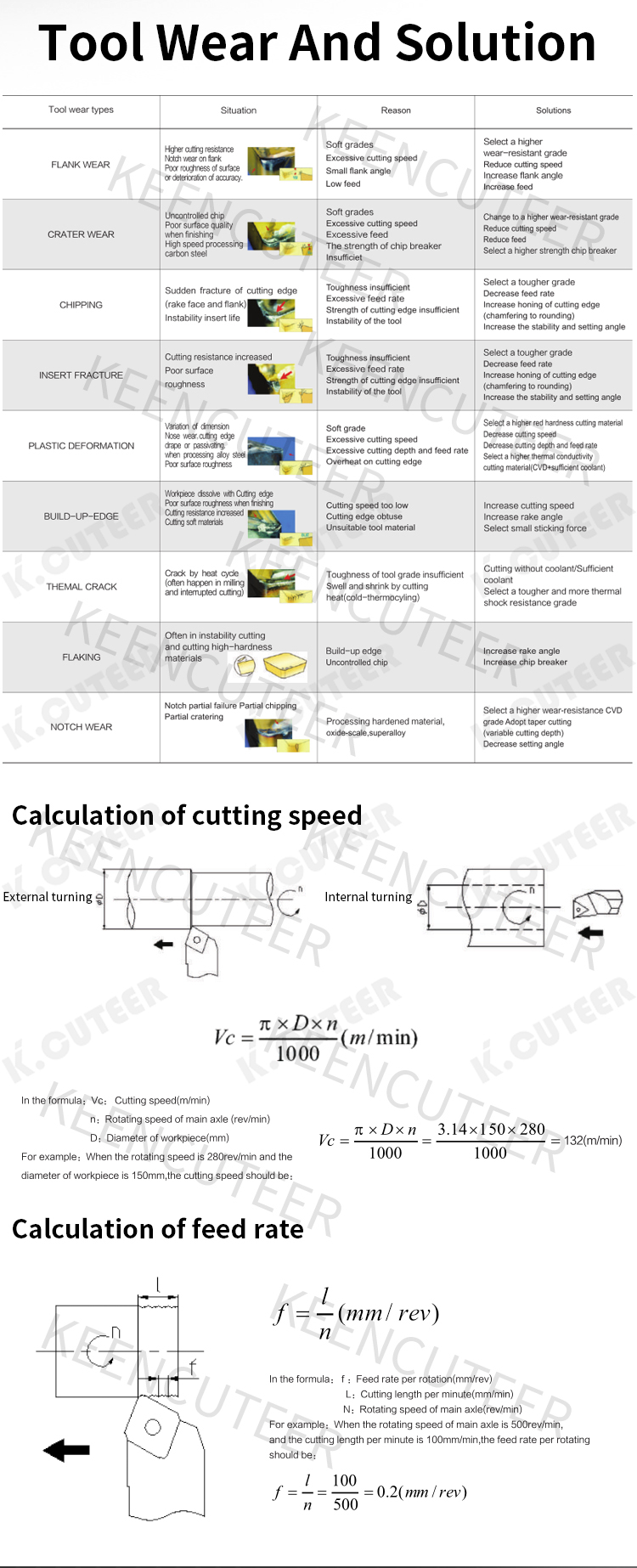

Exceptional Wear Resistance: Significantly outperforms carbide and ceramic tools when machining abrasive materials, leading to a dramatic increase in tool life—often by 50 to 100 times.

High-Speed Capability: Enables very high cutting speeds (Vc), drastically reducing machining cycle times and improving productivity.

Superior Surface Finish: Produces excellent and consistent surface quality, often eliminating the need for secondary finishing operations.

Low Cutting Forces: The sharp, polished edge of PCD generates lower cutting forces, reducing the risk of part deformation, especially in thin-walled components.

These inserts are ideally suited for machining:

High-Silicon Aluminum Alloys (e.g., AlSi12, AlSi17Cu4)

Copper and Copper Alloys

Sintered Tungsten Carbide (pre-sintered state)

Fiber-Reinforced Plastics (FRP) like CFRP and GFRP

Graphite, Wood Composites, and other highly abrasive non-metals.

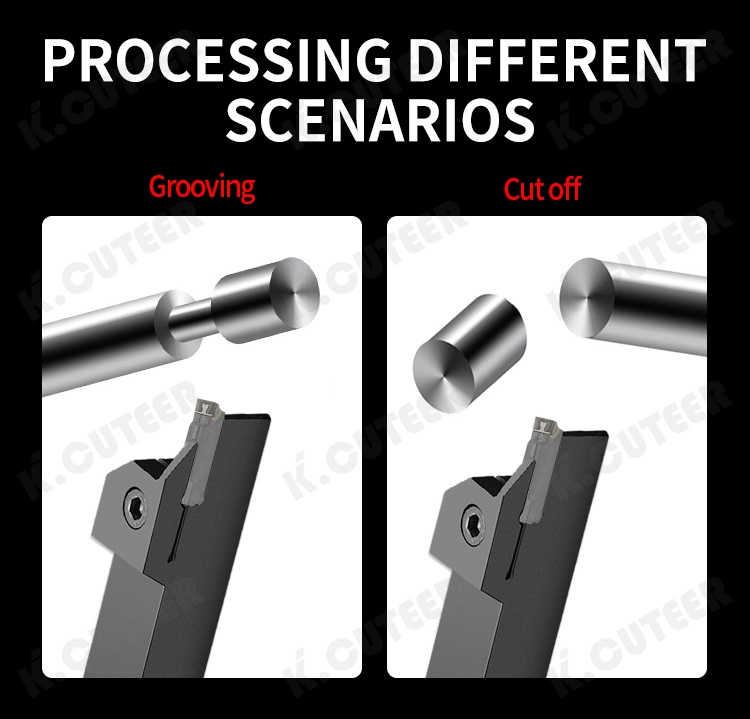

MGMN PCD inserts are primarily used in:

Face Milling

Shoulder Milling

Contour Milling